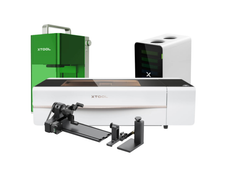

Laser cutters and engravers are machines that use a high-powered laser beam to cut, engrave, or etch various materials. laser cutters and engravers are versatile and precise machines that are widely used in industries such as manufacturing, prototyping, and design. They are also popular among hobbyists and makers, who use them to create a variety of projects and products.

Here are some top laser cutter features:

- Versatile capabilities

- High precision

- Speed - engrave and etch quickly

- Non-contact cutting

Laser Cutters & Engravers Collections

All Laser Cutters & Engravers

About Laser Cutters & Engravers

What is laser cutting and engraving?

Laser cutting and engraving are processes that use a high-powered laser beam to cut or engrave various materials. Here's a brief overview of each process:

Laser Cutting: Laser cutting is a process in which a high-powered laser beam is used to cut through a material. The laser beam is directed at the material, and the intense heat of the beam vaporizes or melts the material, creating a clean and precise cut. Laser cutting is used for a wide range of materials, including metals, plastics, woods, fabrics, and more. It is often used in manufacturing, prototyping, and fabrication applications to create precise, complex shapes and patterns.

Laser Engraving:

Laser engraving is a process in which a high-powered laser beam is used to remove material from the surface of a material, creating a permanent marking. The laser beam is focused on the surface of the material, and the heat of the beam causes the material to vaporize or melt, leaving behind a permanent mark. Laser engraving is commonly used to create logos, serial numbers, and other identifying marks on products and components. It is also used in the art and craft industry to create intricate designs on a wide range of materials.

How do laser cutters and engravers work?

Laser cutters work by using a high-powered laser beam to cut through a material. Here's a step-by-step overview of how a laser cutter works:

- The material to be cut is placed on the cutting bed of the laser cutter. The cutting bed is usually a flat surface that can be moved up and down or side to side to position the material under the laser beam.

- The laser cutter is programmed with the desired cutting pattern, which is typically created using specialized design software.

- The laser beam is generated by a laser tube or other laser source and directed onto the material by a series of mirrors or lenses.

- As the laser beam comes into contact with the material, it heats up the material and vaporizes or melts it, creating a clean and precise cut.

- The laser cutter continues to move the laser beam over the material, following the programmed cutting pattern, until the entire design is complete.

- Once the cutting is complete, the material is removed from the cutting bed.

What materials can you cut with a laser cutter?

Laser cutters are capable of cutting a wide range of materials, including wood, acrylic, plastic, fabric, and more. Some desktop laser engravers are capable of etching metals, too. They are often used in manufacturing, prototyping, and fabrication applications to create precise, complex shapes and patterns. The precision and accuracy of laser cutting make it an attractive option for creating parts and components that require high tolerances and tight specifications.

How much does a laser cutter cost?

The cost of a laser cutter can vary widely depending on several factors such as size, power, features, and brand. Here are some general price ranges for different types of laser cutters:

- Desktop laser cutters can range in price from around $1,000 to $10,000. These are smaller machines typically used for hobbyists and small businesses.

- Mid-range laser cutters typically range in price from $10,000 to $25,000. These machines are larger and more powerful than entry-level machines and are suitable for medium-sized businesses.

- Industrial laser cutters can range in price from $25,000 to over $150,000, depending on the size, power, and features. These machines are large and powerful and are designed for heavy-duty cutting applications.