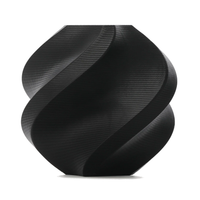

Bambu Lab Bambu Lab Black ABS Filament - 1.75mm (1kg)

Bambu Lab ABS is engineered for strength, durability, and heat resistance. It is compatible with most 3D printers and optimized for use with Bambu Lab X1 series and P1 series printers. This filament features RFID technology for seamless integration with the Bambu Lab AMS, ensuring automatic material recognition and optimal printing settings.

- Compatible with RFID Technology

- Durable, High-Temperature Material

- Nozzle Temp: 220 - 250 °C

- Bed Temp: 85 - 100 °C

- Enclosure Recommended for Best Results

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Bambu Lab ABS

Bambu ABS is a reliable 3D printing filament known for its strength, durability, and high impact resistance. It also offers excellent heat and water resistance, making it perfect for projects that require stability at moderate temperatures and in humid or wet environments. Ideal for a variety of 3D printing applications.

Strong & Durable ABS Filament

Bambu Lab ABS is a top choice for makers needing tough, reliable prints. With superior mechanical properties, it outperforms standard PLA and PETG, making it perfect for functional parts and engineering projects.

- Excellent strength and durability

- Ensures long-lasting, reliable prints

- Ideal for functional parts, prototypes, and engineering components

Water-Resistant Performance

Bambu Lab ABS offers excellent water resistance, making it a great choice for prints exposed to moisture or wet environments. Enjoy added durability and longevity for your projects.

- Suitable for use in wet or humid environments

- Enhances durability and lifespan of printed parts

- Ideal for outdoor or moisture-prone applications

Tough & Impact Resistant

Bambu Lab ABS delivers outstanding toughness and can withstand repeated impacts, collisions, and drops. It maintains impressive impact resistance even in low-temperature conditions.

- Exceptional toughness for demanding applications

- Withstands impacts, collisions, and falls

- Maintains strength and durability at low temperatures

| Recommended Print Settings | |

|---|---|

| Drying Settings (Blast Drying Oven) | 80 °C, 8 hours |

| Printing and Storage Humidity | < 20% RH (sealed with desiccant) |

| Nozzle Temperature | 240 – 270 °C |

| Bed Temperature (with glue) | 80 – 100 °C |

| Printing Speed | < 300 mm/s |

| Physical Properties | |

| Density | 1.05 g/cm³ |

| Vicat Softening Temperature | 94 °C |

| Heat Deflection Temperature | 87 °C |

| Melting Temperature | 200 °C |

| Melt Index | 34.2 ± 3.8 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 33 ± 3 MPa |

| Breaking Elongation Rate | 10.5 ± 1.0% |

| Bending Modulus | 1880 ± 110 MPa |

| Bending Strength | 62 ± 4 MPa |

| Impact Strength | 39 ± 3.6 kJ/m² |