Bambu Lab Bambu Lab Black PA6-CF Filament - 1.75mm (0.5kg)

The Bambu Lab PA6-CF Filament is a high-performance carbon fiber reinforced PA6 (Nylon 6) filament, known for its exceptional thermal resistance and superior stiffness and strength properties in dry environments. It is an ideal choice for printing load-bearing structural components.

- Superior Strength and Stiffness

- Toughness & Vibration Resistance

- Exceptional Thermal Resistance

- Comes with High Temperature Reusable Spool

- Recommended use with a Hardened Steel nozzle sized 0.6mm or larger

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Bambu Lab PA6-CF

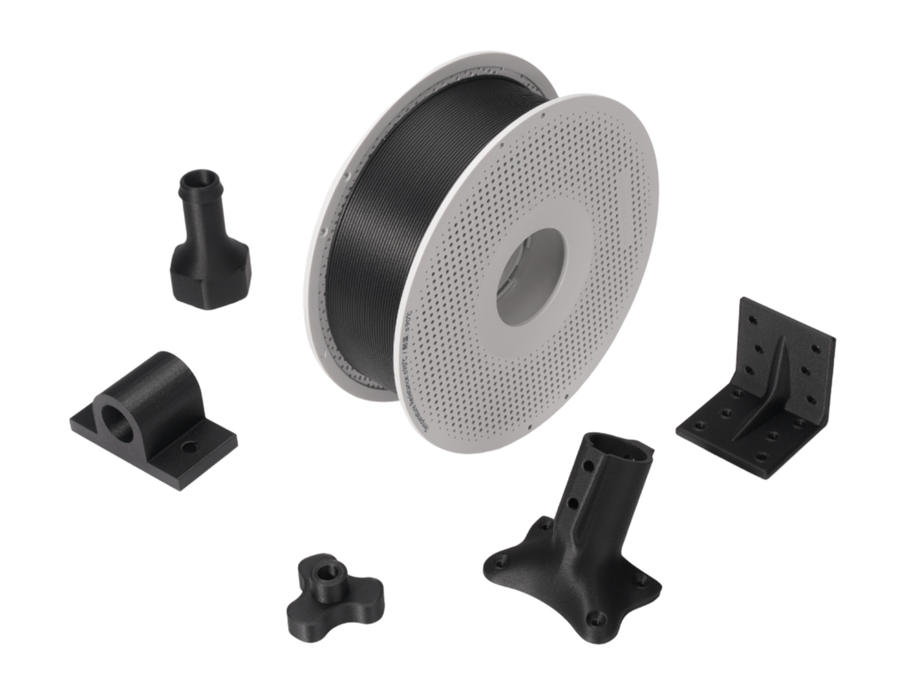

Engineered Strength for Dry Environments

The Bambu Lab PA6-CF delivers significantly enhanced stiffness and strength in dry environments while also offering excellent heat and impact resistance. Similar to other Bambu CF filaments, these exceptional mechanical properties make it an ideal choice for printing fixtures, clamps, automotive and mechanical components, as well as various structural and engineering parts designed for use in dry conditions.

Key Features of the Bambu Lab PA6-CF:

- Excellent rigidity and strength in dry environments

- Offers superior impact and vibration resistance

- Suitable for withstanding impact, collision, and vibration

- Ideal for load-bearing components

- Thermal resistance up to 186℃

- Diameter: 1.75mm +/- 0.03mm

Superior Strength and Stiffness

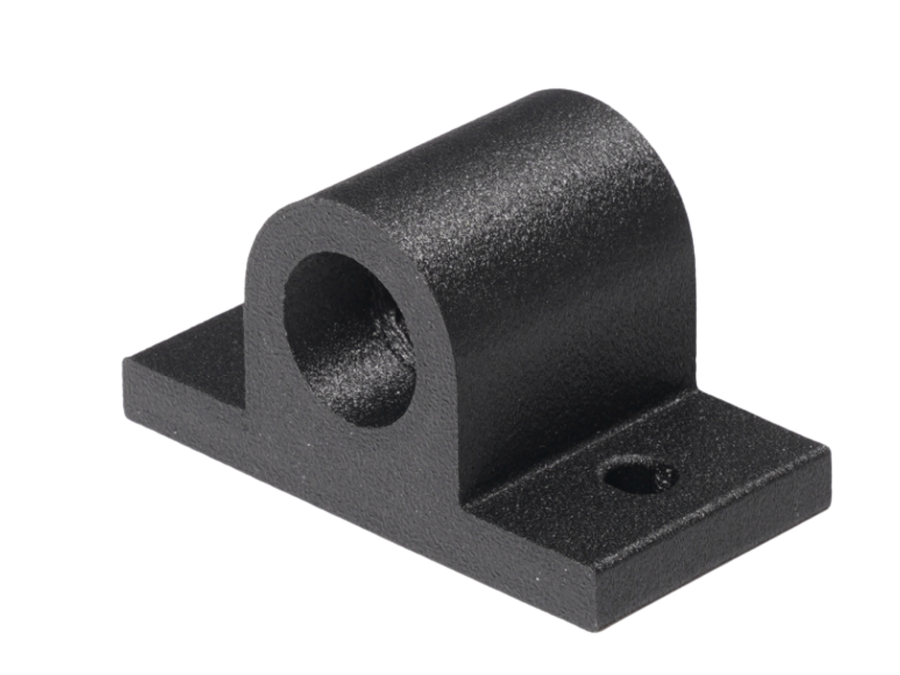

As a high-performance filament, PA6-CF keeps superior stiffness and strength properties in dry environments, making it perfect for printing load-bearing structural components.

- Carbon fiber reinforcement offers high stiffness, strength, heat, and impact resistance

- Ideal for printing fixtures, clamps, automotive/mechanical components, and structural parts

- Best suited for applications in dry environments

Impact & Vibration Resistance

The prints of PA6-CF usually become tougher and more resistant to impacts, drops, and collisions when they get damp.

- Bambu PA6-CF offers excellent impact resistance, ensuring effective vibration resistance for your prints.

- It is commonly used to print models that need to withstand impact, collision, and vibration.

Exceptional Thermal Resistance

| Filament | Heat Deflection Temperature / ℃ (0.45 MPa) |

| PLA Basic | 57 ℃ |

| PETG Basic | 69 ℃ |

| ABS | 87 ℃ |

| ASA | 100 ℃ |

| PC | 117 ℃ |

| PA6-CF | 186 ℃ |

| PAHT-CF | 194 ℃ |

| PET-CF | 205 ℃ |

Parameter Comparison

| Description | PA6-CF | PAHT-CF |

|---|---|---|

| Composition | Nylon 6, carbon fiber | PA12 and other long-chain PA, carbon fiber |

| AMS Compatibility | NO | YES |

| Dry Out Before Use | Required | Required |

| Printing Speed | < 100 mm/s | < 100 mm/s |

| Printer Type | Enclosure | Enclosure |

| Toughness (Impact Strength - XY, dry state) | 40.3 kJ/m² | 57.5 kJ/m² |

| Toughness (Impact Strength - XY, wet state) | 57.2 kJ/m² | 62.3 kJ/m² |

| Strength (Bending Strength - XY, dry state) | 151 MPa | 125 MPa |

| Strength (Bending Strength - XY, wet state) | 95 MPa | 115 MPa |

| Layer Strength (Bending Strength - Z, dry state) | 80 MPa | 61 MPa |

| Layer Strength (Bending Strength - Z, wet state) | 45 MPa | 49 MPa |

| Stiffness (Bending Modulus - XY, dry state) | 5460 MPa | 4230 MPa |

| Stiffness (Bending Modulus - XY, wet state) | 3560 MPa | 3640 MPa |

| Layer Adhesion (Impact Strength - Z, dry state) | 15.5 kJ/m² | 13.3 kJ/m² |

| Heat Resistant(HDT, 0.45 MPa) | 186 ℃ | 194 ℃ |

| Saturated Water Absorption Rate / % (25 °C,55% RH) | 2.35 | 0.88 |

Recommended Printing Settings

| Description | Value |

|---|---|

| Nozzle Temperature | 260 - 290 °C |

| Bed Temperature (with Glue) | 80 - 100 °C |

| Drying Settings before Printing | 80 °C, 8 - 12 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Printing Speed | < 100 mm/s |

Physical Properties

| Property | Value |

|---|---|

| Density | 1.09 g/cm³ |

| Vicat Softening Temperature | 212 °C |

| Heat Deflection Temperature | 186 °C |

| Melting Temperature | 223 °C |

| Melt Index | 6.8 ± 0.6 g/10 min |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 102 ± 7 MPa |

| Breaking Elongation Rate | 5.8 ± 1.6 % |

| Bending Modulus | 5460 ± 280 MPa |

| Bending Strength | 151 ± 8 MPa |

| Impact Strength | 40.3 ± 2.5 kJ/m² |

Tips & Tricks

- Dry the filament at 80℃ for 10 hours before use for optimal printing performance. Find filament dryers here.

- PA6-CF is sensitive to humidity; dry it before and after storage.

- Use a Hardened Steel nozzle (0.6mm+) instead of Stainless Steel.

- For stronger prints, dampen and soften them beforehand.

- For optimal performance, absorbing water is not recommended for printing models that require high strength, stiffness, and dimensional stability.

- Remove support structures within 2 hours to maximize post-processing.

- If supports are hard to remove, dry and cool prints before removal.

- Use paint, wax, or waterproof coatings to inhibit water absorption and softening.

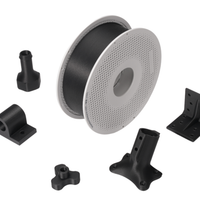

What's in the Box

All Bambu Filaments are shipped in individual packages shown below:

- Filament with Spool(1) & Desiccant(1)

- Package(1)