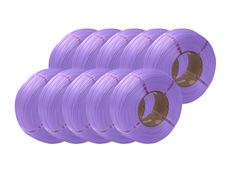

Bambu Lab Bambu Lab Matte PLA Filament - 1.75mm (1kg)

Bambu Lab Matte PLA is a reliable, beginner-friendly 1.75 mm filament designed for smooth, consistent 3D printing. It offers easy printing, an excellent matte surface quality, and eco-friendly biodegradability. Save with refills and 10-packs options!

- Matte Surface Finish

- Compatible with RFID Technology

- Compatible with AMS & AMS Lite

- Eco-friendly Refill Option

- Available in spools, refills, and 10-packs

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Bambu Lab PLA Matte

Bambu Lab PLA Matte is a versatile 1.75 mm filament compatible with virtually any 3D printer and fine-tuned for optimal results on Bambu Lab printers. This filament delivers hassle-free, consistent printing with matte finishes, making it perfect for a wide range of everyday projects. It offers fast printing speeds, strong layer bonding, and impressive durability. Its eco-friendly, biodegradable composition and RFID-enabled smart printing support ensure easy setup and sustainable use. Bambu Lab PLA Matte provides excellent value for users seeking dependable, high-quality 3D prints for beginners and professionals alike.

Key Features of the Bambu Lab PLA Matte 3D Printer Filament:

- Ideal for Clean, Aesthetic Prints with Performance and Value

- Compatible with RFID Technology on the Bambu Lab AMS

- Recommended Nozzle Temp: 190 - 230 °C

- Recommended Bed Temperature: 35 - 45 °C

- Glue Stick Recommended

- Available as a Refill for a More Eco-Friendly Option

- Reuse Previous, Print, or Purchase a Bambu Reusable Spool

- Download Here if Printing (also available on your Bambu Lab 3D Printer)

Soft Matte Color Palette

Bambu Lab PLA Matte features a refined selection of over 20 soft, muted colors with a smooth, matte finish. Each shade delivers a clean, minimalistic look that is perfect for aesthetic prints, fashion designs, and decor pieces.

- Soft, subtle matte shades

- Minimalist look for design and decor prints

High Quality Prints with Ease

Bambu Lab PLA Matte delivers precise, reliable printing at high speeds.

- Easy to use for all skill levels

- Print up to 270 mm/s with excellent results (tested settings with 0.4 mm nozzle, 0.4 mm line width, 0.2 mm layer height)

Recommended Printing Settings

| Description | Value |

|---|---|

| Nozzle Temperature | 190 - 230 °C |

| Bed Temperature (with PVP Glue) | 35 - 45 °C |

| Drying Settings before Printing | 50 °C, 8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Printing Speed | < 300 mm/s |

Physical Properties

| Property | Value |

|---|---|

| Density | 1.31 g/cm³ |

| Vicat Softening Temperature | 63 °C |

| Heat Deflection Temperature | 52 °C |

| Melting Temperature | 163 °C |

| Melt Index | 18.0 ± 3.2 g/10 min |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 30 ± 5 MPa |

| Breaking Elongation Rate | 14.8 ± 4.2 % |

| Bending Modulus | 2360 ± 250 MPa |

| Bending Strength | 53 ± 6 MPa |

| Impact Strength | 19.2 ± 3.7 kJ/m² |

How Do I Refill my Bambu Lab Reusable Spool?

Step 1 - Align Refill with Spool

- Find the locator (a tiny block on the wide piece).

- Align it with the notch on the inner ring of the filament roll.

- Insert the wide piece into the filament roll.

Step 2 - Insert Narrow Piece & Lock In Spool

- Insert the narrow piece and align the groove of each piece inside of the spool until it's pushed firmly into the wide piece.

- Once it's pushed firmly into the wide piece, rotate the narrow piece clockwise until it slides into place and you hear it lock.

Step 3 - Install Shim & Remove Strips

- Install the spacing shim inside the spool (under the triangle)

- Pull out the 4 plastic strips

Accessory Compatibility

| Recommended | |

|---|---|

| AMS & AMS lite | AMS, AMS 2 Pro, AMS HT & AMS lite |

| Build Plate | Cool Plate SuperTack, Smooth PEI Plate, Textured PEI Plate |

| Hotend | All Size / Material |

Printing Tips

- Drying filament ensures consistent print quality. Find filament dryers here.

- In a blast drying oven: 50°C for 8 hrs.

- In an AMS 2 Pro and AMS HT: 55°C for 8 hrs.

- On an X1 printer's heatbed: 60 - 70°C for 12 hrs.

- Store filament in a dry place to prevent moisture absorption to ensure consistent print quality.

- Refills are compatible with MatterHackers Reusable Spool Holder.

Downloads

| Technical Data Sheet | Safety Data Sheet | RoHS | Hex Code |

|---|

What's in the Box

*Product received corresponds to the selected option (spool or refill). Images are for reference only.

Filament with Spool

Filament Refill