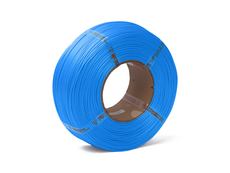

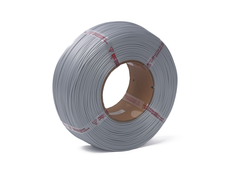

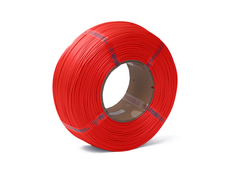

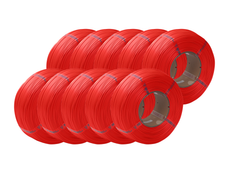

Bambu Lab Cyan PLA Filament Refill 10 Pack - 1.75mm (1kg)

Bambu Lab Basic PLA is a reliable, beginner-friendly 1.75 mm filament designed for smooth, consistent 3D printing. It offers easy printing, an excellent surface quality, and eco-friendly biodegradability. Save with refills and 10-packs options!

- Smooth Surface Finish

- Compatible with RFID Technology

- Compatible with AMS & AMS Lite

- Eco-friendly Refill Option

- Available in spools, refills, and 10-packs

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Bambu Lab PLA Basic

Bambu Lab PLA Basic is a versatile 1.75 mm filament compatible with virtually any 3D printer and fine-tuned for optimal results on Bambu Lab printers. This filament delivers hassle-free, consistent printing with smooth finishes, making it perfect for a wide range of everyday projects. It offers fast printing speeds, strong layer bonding, and impressive durability. Its eco-friendly, biodegradable composition and RFID-enabled smart printing support ensure easy setup and sustainable use. Bambu Lab PLA Basic provides excellent value for users seeking dependable, high-quality 3D prints for beginners and professionals alike.

Key Features of the Bambu Lab PLA Basic 3D Printer Filament:

- Balanced Performance and Value for Everyday Printing

- Compatible with RFID Technology on the Bambu Lab AMS

- Recommended Nozzle Temp: 190 - 230 °C

- Recommended Bed Temperature: 35 - 45 °C

- Glue Stick Recommended

- Available as a Refill for a More Eco-Friendly Option

- Reuse Previous, Print, or Purchase a Bambu Reusable Spool

- Download Here if Printing (also available on your Bambu Lab 3D Printer)

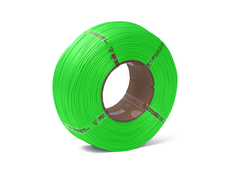

Easy Printing in Every Color

Bambu Lab PLA Basic offers over 20 vibrant colors that maintain consistency across prints for a flawless, uniform finish every time. Designed for ease of use, this filament delivers reliable printing right from the start. Ideal for hobbyists and makers, it ensures dependable, hassle-free results.

- Endless shades with uniform finish

- Beginner-friendly setup and calibration

Durability with Ease

Bambu Lab PLA Basic features an expertly crafted formula that delivers strong layer adhesion, improved impact resistance, and exceptional durability. Supporting high-speed printing, this filament reduces print times without sacrificing quality.

- Strong layer adhesion and durability for long-lasting prints

- Easy to use with reliable, high-quality results

- Supports fast printing speeds without quality loss

Recommended Printing Settings

| Description | Value |

|---|---|

| Nozzle Temperature | 190 - 230 °C |

| Bed Temperature (with Glue) | 35 - 45 °C |

| Drying Settings before Printing | 50 °C, 8 hrs |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Printing Speed | < 300 mm/s |

Physical Properties

| Property | Value |

|---|---|

| Density | 1.24 g/cm³ |

| Vicat Softening Temperature | 57 °C |

| Heat Deflection Temperature | 54 °C |

| Melting Temperature | 160 °C |

| Melt Index | 42.4 ± 3.5 g/10 min |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 35 ± 4 MPa |

| Breaking Elongation Rate | 12.2 ± 1.8 % |

| Bending Modulus | 2750 ± 160 MPa |

| Bending Strength | 76 ± 5 MPa |

| Impact Strength | 26.6 ± 2.8 kJ/m² |

How Do I Refill my Bambu Lab Reusable Spool?

Step 1 - Align Refill with Spool

- Find the locator (a tiny block on the wide piece).

- Align it with the notch on the inner ring of the filament roll.

- Insert the wide piece into the filament roll.

Step 2 - Insert Narrow Piece & Lock In Spool

- Insert the narrow piece and align the groove of each piece inside of the spool until it's pushed firmly into the wide piece.

- Once it's pushed firmly into the wide piece, rotate the narrow piece clockwise until it slides into place and you hear it lock.

Step 3 - Install Shim & Remove Strips

- Install the spacing shim inside the spool (under the triangle)

- Pull out the 4 plastic strips

Accessory Compatibility

| Recommended | |

|---|---|

| AMS & AMS lite | AMS, AMS 2 Pro, AMS HT & AMS lite |

| Build Plate | Cool Plate SuperTack, Smooth PEI Plate, Textured PEI Plate |

| Hotend | All Size / Material |

Printing Tips

- Drying filament ensures consistent print quality. Find filament dryers here.

- In a blast drying oven: 50°C for 8 hrs.

- In an AMS 2 Pro and AMS HT: 55°C for 8 hrs.

- On an X1 printer's heatbed: 60 - 70°C for 12 hrs.

- Store filament in a dry place to prevent moisture absorption to ensure consistent print quality.

- Refills are compatible with MatterHackers Reusable Spool Holder.

Downloads

What's in the Box

*Product received corresponds to the selected option (spool or refill). Images are for reference only.

Filament with Spool

Filament Refill