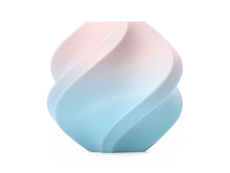

Bambu Lab Bambu Lab Dawn Radiance Silk (Rainbow) Multi-Color PLA Filament - 1.75mm (1kg)

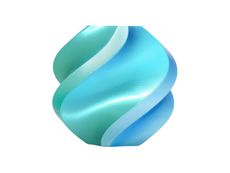

Bambu Lab Silk Multi-Color PLA blends multiple vibrant hues into a single strand, creating smooth, flowing gradients with a glossy, silk-like finish. Each print displays dynamic color shifts, adding depth and sophistication to decorative and artistic projects.

- Seamlessly transitions between colors for visually striking designs

- Produces consistent, high-quality layers from start to finish

- Ideal for decorative models, figurines, and display pieces

- Strongly recommend drying filament before use for best quality prints

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Bambu Lab PLA Silk Multi-Color Filament

Bambu Lab PLA Silk Multi-Color merges multiple silk tones, resulting in a natural multi-tone gradient. Prints maintain the silky smooth surface and high-gloss shine of standard silk PLA while adding a unique multi-color dimension, making it ideal for aesthetic parts and decorative objects.

Key Features of Bambu Lab PLA Silk Multi-Color Filament:

- Multi-color silk blend creates smooth gradients with a glossy, silky finish

- Easy to print with reliable adhesion and consistent results

- Perfect for decorative models, props, and artistic design

- Gradient appearance can be adjusted by rotating the filament orientation

- Dry at 55 °C for 8 hours before printing for best results

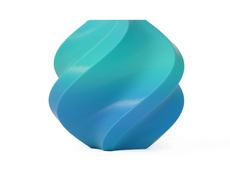

Silky Gradient Finish

Elevate standard prints into visually stunning pieces with a smooth, flawless multi-color gradient. The glossy, silk-like surface of this PLA filament adds depth and elegance, while maintaining ease and reliability.

- Seamless color transitions appear depending on filament orientation

- High-gloss silk appearance with natural color transitions

Achieve Maximum Shine

The glossiness of silk filament prints can be adjusted by tuning temperature and print speed. Higher nozzle temperatures and slower print speeds produce a shinier, smoother surface.

- Recommended Nozzle Settings: 230-240°C

- Recommended Outer Wall Speed: 30-60mm/s

Recommended Printing Settings

| Description | Value |

|---|---|

| Nozzle Temperature | 210 - 240°C |

| Bed Temperature (with Glue) | 35 - 45°C |

| Drying Settings before Printing | 55°C, 8 hrs |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Printing Speed | < 250 mm/s |

Physical Properties

| Property | Value |

|---|---|

| Density | 1.32 g/cm³ |

| Vicat Softening Temperature | 56°C |

| Heat Deflection Temperature | 53°C |

| Melting Temperature | 152°C |

| Melt Index | 20.5 ± 1.2 g/10 min |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 27 ± 4 MPa |

| Breaking Elongation Rate | 3.5% ± 0.6% |

| Bending Modulus | 2370 ± 150 MPa |

| Bending Strength | 66 ± 4 MPa |

| Impact Strength | 24.5 ± 1.7 kJ/m² |

Printing Tips

- Drying filament at 55°C for 8 hrs before ensures consistent print quality. Find filament dryers here.

- To optimize print quality, it is strongly recommended to reduce outer wall speed to 40 mm/s.

- Some filament rotation is possible, resulting in unique gradient effects; non-A-series printers ensure more uniform results.

- Gradient results vary with filament consumption; control the appearance by modifying infill density, print count, or spool start position.

- Color transitions depend on filament length: ~20m (65g+) per color segment, ~40m (125g+) for two-color, and ~80m (250g+) or more for four-color effects.

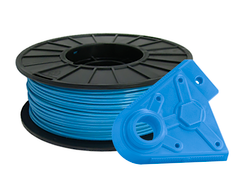

What's in the Box

1 Filament with Spool & Desiccant

1 Package