Bambu Lab Bambu Lab Support for PA / PET Filament - 1.75mm

Bambu Lab Support for PA & PET is used as a support interface for easy breakaway, specifically developed for PA, PET, and their carbon fiber reinforced composites. With quick removal, this material allows for prints to be immediately used after printing and simplifies the printing process from beginning to end.

- Easy support removal with no tools needed

- Smooth support interface

- Comes with a high-temperature reusable spool

- Compatible with AMS and RFID Technology

- Incompatible with AMS lite

- Best results achieved with an enclosed printer and drying filament before use

| List Price: | $51.99 |

|---|---|

| Price: | $51.99 |

| Price: | $... |

| Order Now: | Ships calculating... Free U.S. Shipping |

Bambu Lab Support for PA & PET

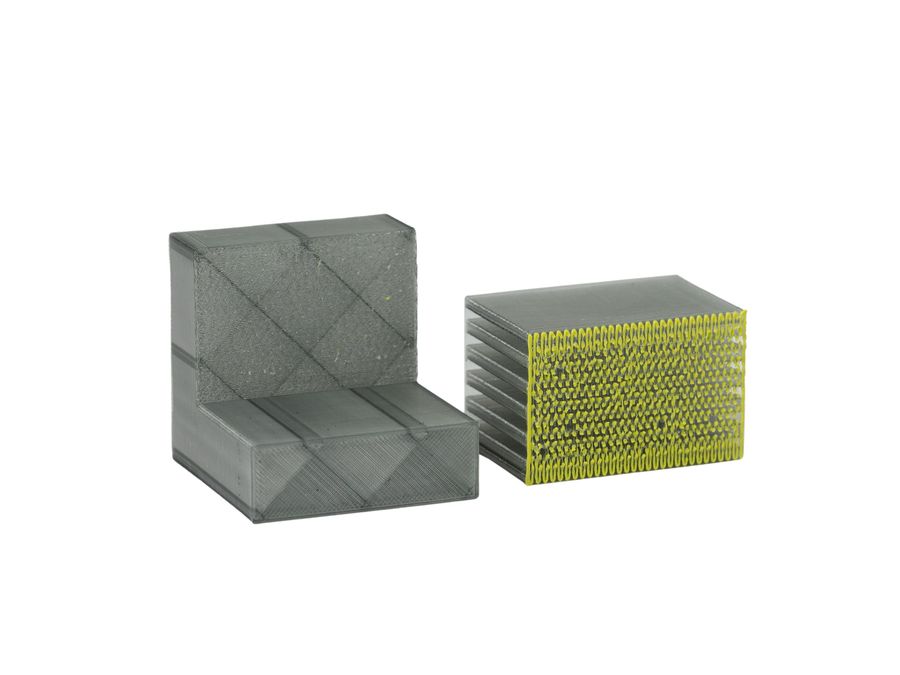

Easy Support Removal

Bambu Lab Support Filament for PA & PET is specially formulated to minimize fusion with PA and PET, allowing for easy support removal. Due to the polarity of the support filament being different from PA or PET, the support material provides precision and reliability, allowing you to print even the most complex designs with ease.

Key Features of the Bambu Lab Support Filament for PA and PET:

- Easily removable by hand

- Provides a smooth, reliable support interface

- Optimized use on PAHT-CF, PA6-CF, PET-CF, and PA6-GF

- Designed only for support usage

- Comes with a high-temperature reusable spool

- Compatible with AMS (not AMS Lite) and RFID technology

- Best results achieved with an enclosed printer and drying filament before use

Superior Support Interface Quality

Support for PA and PET bonds weakly with PA and PET by acting as an interface, ensuring precision and reliability when peeling away.

- Peels away easily without damaging the model

- Contact areas remain smooth, requiring no further post-processing

- Ensures better print accuracy since the model sits on a stable, well-bonded support

Recommended Printing Settings

| Description | Value |

|---|---|

| Nozzle Temperature | 280 - 300°C |

| Bed Temperature (with Glue) | 80 - 110°C |

| Drying Settings before Printing | 80°C, 12 hrs |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Printing Speed | < 100 mm/s |

Physical Properties

| Property | Value |

|---|---|

| Density | 1.17 g/cm³ |

| Vicat Softening Temperature | N/A |

| Heat Deflection Temperature | N/A |

| Melting Temperature | 255°C |

| Melt Index | 29.2 ± 2.1 g/10 min |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | N/A |

| Breaking Elongation Rate | N/A |

| Bending Modulus | N/A |

| Bending Strength | N/A |

| Impact Strength | N/A |

Printing Tips

- Drying support filament ensures consistent print quality. Find filament dryers here.

- In a blast drying oven: 80°C for 8 hrs.

- On a printer's heatbed: 90°C for 10 hrs.

- It is recommended to remove the support structures within 2 hours of printing to avoid sticking caused by moisture absorption. If needed, dry the model to ease removal.

What's in the Box

1 Filament with Spool & Desiccant

1 Package