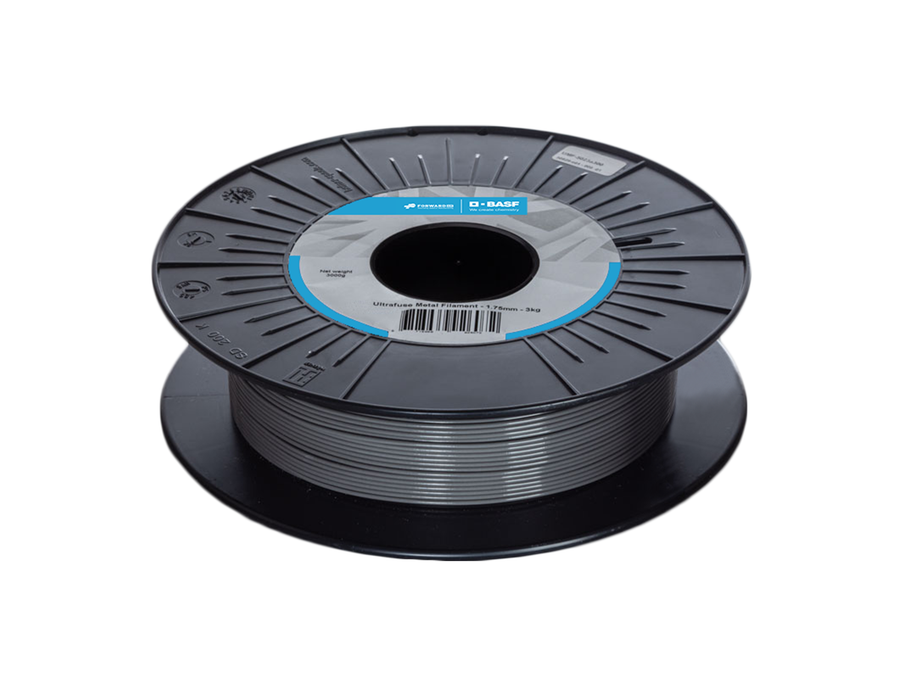

Forward AM Forward AM Ultrafuse 17-4 PH Metal 3D Printing Filament - 2.85mm (3kg)

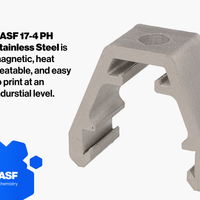

BASF's Ultrafuse 17-4 PH Metal 3D Printing Filament is an industrial material that makes it easy to produce metal-polymer parts on a desktop 3D printer. It is nearly 100% solid 17-4 PH stainless steel.

- 3D printed parts made of nearly 100% solid 17-4 stainless steel

- Reliable metal production via desktop 3D printing

- Convenient and cost-effective

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

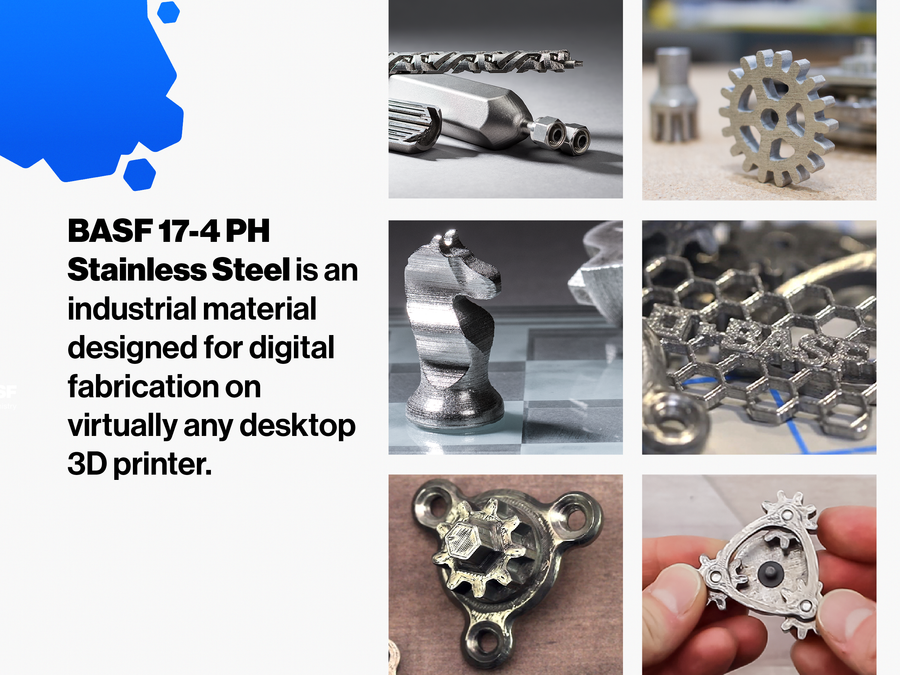

BASF Ultrafuse 17-4 PH Metal 3D Printing Filament is an industrial material designed for digital fabrication on virtually any desktop 3D printer. When debound and sintered, users are left with a 3D printed part made of nearly 100% solid 17-4 stainless steel. For best bed adhesion results, we recommend a glass bed with Dimafix. Learn how to 3D print with metal filament by checking out our article here or watching the video below.

RELIABLE METAL PRODUCTION VIA DESKTOP 3D PRINTING

Combining the processes of Fused Filament Fabrication (FFF) and Metal Injection Molding (MIM), metal additive manufacturing on a desktop 3D printer is now even easier and more attainable for advanced makers with BASF's Ultrafuse 17-4 PH Metal 3D Printing Filament! Use any FFF 3D printer like the BCN3D Epsilon W50, Ultimaker S5 or Pulse to produce metal-polymer parts that are industrially debound and sintered, leaving a final product that is nearly 100% solid 17-4 PH stainless steel. Print your parts at your office. Ship them out to be debound and sintered using the BASF Ultrafuse Processing Ticket. Receive a functional metal part ready to go. Investing in BASF's Ultrafuse 17-4 PH Metal 3D Printing Filament is the ideal convenience and cost-effective choice for any maker interested in advancing their prototypes to the next level through metal desktop 3D printing. Note that the processing ticket expires after three months from the date of purchase.

INDUSTRIAL MATERIALS FOR INDUSTRIAL PROJECTS

Interested in dabbling with industrial metal materials for your projects? Ultrafuse 17-4 PH Metal 3D Printing Filament is the solution for you. Made out of over 80% 17-4 stainless steel particles with a polymer base, this metal-polymer filament is specifically engineered to provide fantastic reliable metal 3D printed results for industrial projects via FFF printing. Easily produce a functional metal prototype of your advanced projects starting right from your desktop 3D printer. What kind of projects can you dive into with BASF's Ultrafuse 17-4 PH Metal 3D Printing Filament?

Applications for Stainless Steel Include (but are not limited to):

- Functional Prototyping

- Automotive Parts

- Pipes, pumps and valves for chemicals, gas, and oils

- Parts for tooling and mold inlays with near-surface cooling

- Magnetizable surfaces

LOW INVESTMENT FOR HIGH RETURN

Makers substantially save producing metal prototypes via desktop 3D printing and materials like Ultrafuse 17-4 PH Metal 3D Printing Filament by BASF 3D Printing Solutions. Purchasing entry-level industrial machines and materials can be an expensive commitment for the general public, which is why we're happy to introduce a more affordable option for anyone passionate about small scale, industrial metal production. Take any FFF 3D printer with the appropriate components and upgrades, use cost-effective specialty materials like Ultrafuse 17-4 PH, and ship out your newly 3D printed parts with a processing ticket to be debound, sintered, and quickly returned for the final functional metal product. With BASF's Ultrafuse 17-4 PH Metal 3D Printing Filament, you can do this for any number of projects you have in mind, anytime with your desktop 3D printer.

|

316L |

17-4 PH |

|

|

QUICK AND EASY DEBIND AND SINTER PROCESS

When you order a processing ticket, our staff works together with experts from DSH to have your BASF Ultrafuse 17-4 PH metal parts debound and sintered quickly, with minimal effort on your end. Every spool comes with one BASF Ultrafuse Processing Ticket, with more you can purchase either as an add on or through here. Once your printed green parts (metal-polymer parts that have not been debound or sintered) are delivered to DSH, they work quickly to process your order on a scheduled run over a two day period and ship out your now solid 17-4 PH stainless steel parts back to you the following day. Just make sure to use the ticket within a three month period from when it was purchased.

Purchase a processing ticket. Ship your Ultrafuse green prints, processing ticket code, and form. Receive your now metal parts. All completed quickly and easily with MatterHackers' BASF Ultrafuse Processing Ticket. For details on how to prepare your printed parts for outsource processing, check out our "How to Prepare 3D Printed BASF Ultrafuse 316L Parts for Debinding and Sintering."

PROCESSING SCHEDULE

DSH has Debinding and Sintering runs scheduled the first Tuesday of every month, and parts need to have arrived to DSH on the Friday before. See the schedule below for the days when they will run any properly packaged and shipped Ultrafuse 316L and 17-4 PH parts they have received. What counts as properly packaged and shipped parts? Check out our "How to Prepare Ultrafuse 316L Parts for Debinding and Sintering" guide.

TECHNICAL SPECIFICATIONS

- Requires one BASF Ultrafuse Processing Ticket

- Within 48 business hours of purchase, please expect a follow-up email from a MatterHackers' support team member with your unique processing ticket code, packaging instructions, and form.

- This processing ticket comes with Standard Return Delivery. Parts will return to the customer between 2 - 5 business days AFTER green parts have been debound and sintered. Time of delivery will be based on the sender address' location in proximity to DSH's facility.

- This processing ticket only covers return delivery within the U.S. Additional shipping charges may be applied to customers outside of the U.S. If you want to use a processing ticket and live outside of the U.S., please contact support@matterhackers.com for options.

- Processing tickets expire three months from the date of purchase.

- Recommended Extrusion Temperatures: 230 - 250 °C

- Recommended Bed Temperature: 100 - 120°C

- Recommended Print Surface: Glass Bed with Dimafix Bed Adhesive

- Recommended Nozzle: Any Abrasion Resistant Nozzle

- Make sure your nozzle is 100% purged of other filaments before printing

- Density: 7800kg/m³

- Filament Diameter: 1.75mm / 2.85mm

- Spool Size: 3kg

- Print Speed: 15 - 40mm/s

- Part Cooling: None

Click here to download the Ultrafuse 17-4 PH TDS.