ColorFabb ColorFabb Dark Gray LW-PLA-HT Filament - 1.75mm (0.75kg)

ColorFabb's LW-PLA-HT is a specially formulated filament designed for applications that require increased temperature resistance for their printed structures. It offers better heat resistance, lightweight parts due to an active foaming process, dark colors that are less prone to heat deformation, and parts that take paint well and have good strength. It can be calibrated with a 4-step process and is ideal for RC planes, cosplay accessories, and other lightweight items.

- Increased temperature resistance

- Easy to cut, trim, and sand

- Feather-light with good strength

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

ColorFabb LW-PLA-HT

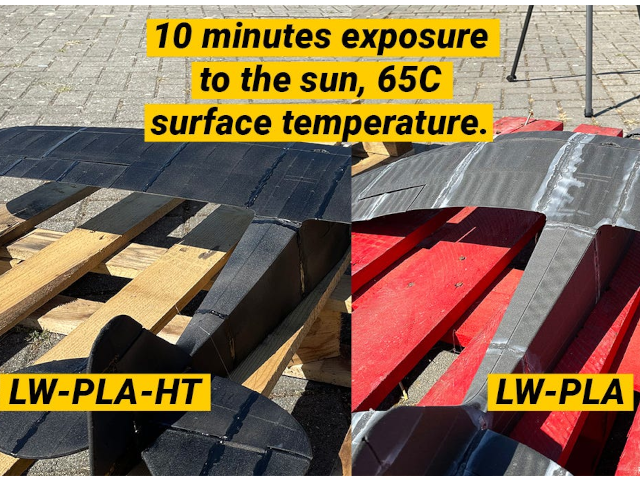

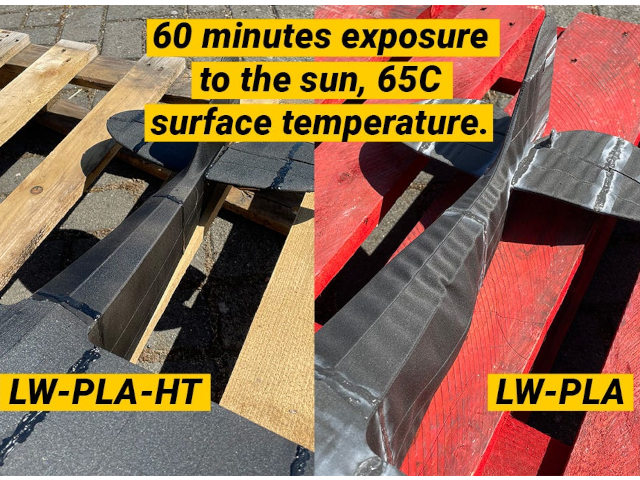

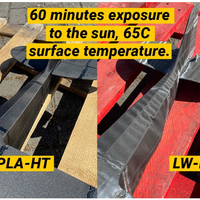

ColorFabb's new and improved LW-PLA-HT filament formulation is specially designed for applications that require increased temperature resistance for their printed structures. Compared to the original LW-PLA, this new formulation offers better heat resistance and can handle external heat sources such as the sun, making it ideal for a range of applications.

LW-PLA-HT is the perfect filament for printing lightweight parts such as RC planes, cosplay accessories, and other lightweight items. The parts printed using this filament are feather-light, yet retain good strength and are easy to cut, trim, and sand.

Here are some of the top features of LW-PLA-HT:

- Increased temperature resistance compared to LW-PLA

- Lightweight parts due to the active foaming process

- Darker colors are less prone to heat deformation

- Takes paint really well

- Feather-light parts with good strength

Upgrading from LW-PLA to LW-PLA-HT

What you need to know when upgrading from LW-PLA to LW-PLA-HT.

CALIBRATE YOUR SETTINGS

YOU ONLY NEED 11 GRAMS OF FILAMENT AND 50 MINUTES PRINTING TIME.

LW-PLA-HT contains a foaming agent which activates around 220C printing temperature (depending on the other settings used). To calibrate your 3D printer settings we developed a simple but effective 4 step process:

- 3D print our calibration cubes.

- Measure the wall thickness of the cubes.

- Enter the values in our Excel file

- Test print to confirm calculated values. Adjust the flow setting until the part has the strength you need.

Step 1.

You can download the files over at Printables click here. Beware that our premade calibration file is for printing at 0.2mm layer height using a 0.4mm nozzle and 40 mm/s print speed. You can change these values to reflect your preferred settings.

Step 2.

After printing the calibration cubes, before removing them label each cube with the printing temperature as reflected in your file settings. You need to measure the thickness of the perimeter line at each side of the cube and use our excel file to process the data.

Step 3.

Insert the values into the excel file included in our files (click here) and have a graph plotted of the average values per cube, for each printing temperature.

We also plotted a secondary graph which shows you the relation between Material Flow [percentage] as a function of the printing temperature. In this graph, you can easily see which percentage of flow you would need at a minimum to achieve the expected perimeter wall thickness. For this graph we used the following calculation: New Material flow = (100% Flow / (max perimeter width / perimeter widht at 210C))

Step 4.

Now you can select a part to test the calculated values you found for your set-up.

Usually, the calculated flow value is lower than you would actually use for a sufficiently strong part. You might need to increase the flow rate by 5-10%. For RC planes we found 230C - 0.2mm layer height - 50/60% flow to result in sufficiently strong prints on our Prusa MK3s

Keep in mind if the pre-made files you bought have very different print speed or layer height values than what you’ve tested with our calibration file, the value for the flow percentage will deviate. It would be best to repeat the calibration file with the key settings such as speed and layer height exactly the same as set in the files you bought.

Curious which values we found? Below you can find the values we found for the LW-PLA-HT colors.

| LW-PLA-HT | ||||||

| 210 | 220 | 230 | 240 | 250 | 260 | |

| LW-PLA-HT Black | ||||||

| Average | 0.455 | 0.535 | 0.8475 | 1.0325 | 1.035 | 0.9675 |

| LW-PLA-HT Olive green | ||||||

| Average | 0.46 | 0.535 | 0.8625 | 1.0175 | 1.0275 | 0.9475 |

| LW-PLA-HT White | ||||||

| Average | 0.46 | 0.545 | 0.88 | 1.0275 | 1.0325 | 0.94 |

| LW-PLA-HT Dark grey | ||||||

| Average | 0.465 | 0.5475 | 0.875 | 1.0375 | 1.055 | 1.0425 |

LW-PLA-HT various colors - wall thickness vs print temperature. Sliced at 0.2mm layerheight / 40 mm/s / 0.4mm nozzle.

Calculating the theoretical material flow percentage needed for an extrusion width similar to the width when printed without foaming at 210c:

New Material flow = (100% Flow / (max perimeter width / perimeter widht at 210C))

* Usually the calculated flow value is lower than you would actually use for a sufficiently strong part. You might need to increase the flow rate by 5-10%. For RC planes we found 230C - 0.2mm layer height - 50/60% flow to result in sufficiently strong prints on our Prusa MK3s

Keep in mind if the pre-made files you bought have very different print speed or layer height values than what you’ve tested with our calibration file, the value for the flow percentage will deviate. It would be best to repeat the calibration file with the key settings such as speed and layer height exactly the same as set in the files you bought.

IN CASE YOU BOUGHT PRE-MADE GCODES / FACTORY FILES

If you don't want to go through the process of calibrating your printer, because you bought pre-made Factory files or G-codes, you can use the following tips & tricks to get a smooth transition to LW-PLA-HT.

3MF / FACTORY FILE

If the RC plane you bought includes premade 3MF / Factory files, then you have the possibility to adjust all relevant settings. We suggest adjusting the following settings:

| LW-PLA | LW-PLA-HT | |

| 1st layer temp | Same as other layers | 200-210C |

| 1st layer flow | Same as other layers | 100% flow |

| 1st layer perimeter | Same as other layers | 2 perimeters |

| layerheight | Sometimes sliced at 0.3mm | Maximum 0.2mm (for 0.4mm nozzle) |

| temperature | 230-240C | 230-240C |

| Flowrate | 40-45% | 50-60% |

| Heated bed | 50C | 60C |

| Bed Adhesion | - | Brim for large parts |

| Adhesion promoter | - | 3DLac |

The first layer is partially stuck on the plate. To prevent these issues we recommend the following settings.

- 1st layer print temp – 200/210C

- 1st layer flow – 100% flow (we’re not activating the foaming agent at these temperatures)

- 1st layer perimeter – 2 perimeters for additional strength.

Perfect flat part and is easy to remove. You can download the Simplify3D template file here: LW-PLA-HT template factory file.

GCODE ONLY

If the plane you bought includes premade G-codes only, then you’ll have to adjust the flow rate manually using your 3D printer control panel. How much you need to increase the flow rate depends on the flow rate that has been set in the file. It’s expected that you need to increase anywhere between 10-20% increased flow rate. Try printing a small part and measuring the thickness of the extruded perimeter to see if this matches what it should be.