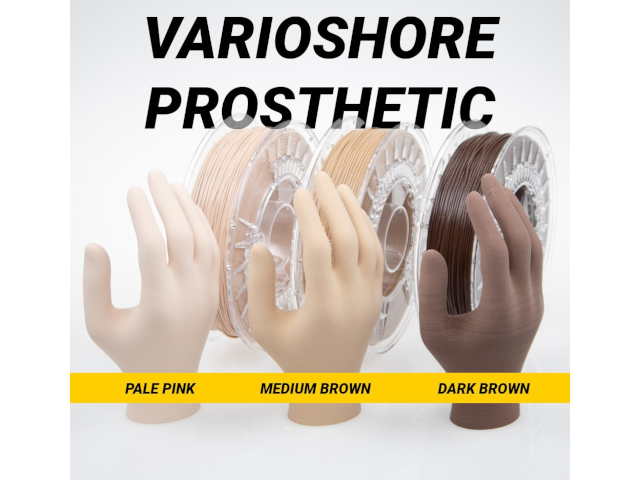

ColorFabb ColorFabb varioShore Prosethetic TPU Filament - 1.75mm (0.70kg) Dark Brown

This revolutionary new material from Colorfabb allows users to vary the density of printed parts by adjusting temperature and material throughput. At temperatures between 200°C and 250°C, the material will start to expand to roughly 1.4 - 1.6 times its original volume. When printed at low flow rates (60-70%, the active foaming properties will cause parts to expand, resulting in very soft printed parts. At temperatures between 190°C and 200°C, the material can be printed without foaming, which results in harder prints when compared to those that utilize Varioshore's active foaming properties.

The base TPU is 92A, which will work with most standard extruder setups.

- Lightweight material

- Soft to the touch finish

- Ideal for prosthetics

- Lower density when foamed, 0.5 to 0.6 g/cm³

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Unique Properties for Printing Prosthetics and Orthotics

This version of varioShore TPU is specially designed for printing prosthetic and orthotic parts. ColorFabb has included silver in our formulation, known for its beneficial properties in these applications.

- Silver inclusion for enhanced properties in prosthetic and orthotic applications

- Available in three skintone colors: Pale Pink, Medium Brown, Dark Brown

- Printing at lower temperatures results in more intense skin tone colors

- Printing at higher temperatures activates the foaming agent, resulting in a softer, less intense powder-like skin tone color

Variable Shore Hardness for Adjustable Density

VarioShore TPU Prosthetic has several distinctive features, including variable shore hardness, reduced weight and density, and a soft touch. Users can adjust the material density by changing the temperature and material throughput, enabling a wide range of printing options. At temperatures between 200 and 250 °C, the materials will start to expand to roughly 1.4-1.6 times their original volume, which reduces the density to 0.7 to 0.9 g/cm³. This means the material can be printed at low flow rates (60-70%) to compensate for active foaming, which, in turn, gives very soft printed parts.

- Reduced weight and density

- Soft touch

- Printing at Temperatures between 200 and 250 °C expands the material to reduce density

FLEXIBLE TO THE TOUCH AND FLEXIBLE IN ITS APPLICATION

Although not quite as lightweight as LW-PLA, ColorFabb varioShore TPU provides users with noticeable weight and density reduction where it matters and the flexibility to use the material in a wide range of other applications. This material is well-suited for producing soft sporting goods, such as bicycle handlebars, or for applications in footwear, such as shoe insoles.

The base TPU is 92A, which will work with most standard extruder set-ups for Bowden and direct drive systems.

By adjusting material flow rates, ColorFabb varioShore enables users to significantly reduces the weight and density of printed parts.

HOW TO SUCCEED WHEN PRINTING WITH VARIOSHORE TPU

The following settings are recommended for successfully printing with this material:

Print Temperature:

- 190°-250°C

Print Speed:

- 20-30mm/s

Print Bed Temperature:

- 20°-40°C

Cooling Fan:

- Users are advised to use the least amount of cooling possible when maximum foaming is desired. For better overhang performance, use 50-100% speed when cooling. Additionally, it is advised to ensure the distance between the nozzle and print surface is not too small, especially if the material is foaming while printing - pressure will need to be released from the hot end to prevent clogging and material feeding issues.

TECHNICAL SPECIFICATIONS

- Spool Size: 0.70kg

- Diameter tolerance: ± 0.1 mm

- Density: 1.2-1.3g/cm-3