FlashForge FlashForge Guider 3 Ultra 3D Printer

The FlashForge Guider 3 Ultra is an ideal choice for commercial-grade additive manufacturing, offering reliable and efficient performance. Thanks to its CoreXY design, this 3D printer combines FlashForge's renowned technology with high-speed printing, high fidelity, and quiet operation in one convenient package. Whether you need high-precision prints or silent printing, the FlashForge Guider 3 Ultra is the perfect all-in-one solution.

- Auto shutdown once the print is done

- Power loss recovery

- Filament run-out reminder

- Dual Extrusion High speed & quiet printing

- Built-in filament drying chamber & Hepa 13 air filtration system

- Flexible and removable steel plate

Disclaimer* Shipping is only covered within the lower 48 states, the following US territories are not covered; Alaska, Hawaii, Puerto Rico, U.S. Virgin Islands, & American Samoa.

| List Price: | $3,499.00 |

|---|---|

| Price: | $3,499.00 |

| Price: | $... |

| Order Now: | Ships calculating... Free U.S. Shipping |

Features of Flashforge Guider 3 Ultra

The FlashForge Guider 3 Ultra is designed to meet the demands of professional 3D printing with outstanding performance and reliability. This 3D printer delivers exceptional speed and efficiency for your business needs, featuring a CoreXY design that showcases FlashForge's renowned technology.

- High-speed printing achieves a print speed of 500mm/s.

- Sturdy construction equipped with extremely robust Z-axis guides and ball screws, ensuring stability for large models and long print jobs.

- Built-in features include a filament drying chamber and a HEPA 13 air filtration system.

- The high-temperature extruder can reach up to 320°C.

- The quick-release nozzle facilitates easy maintenance and nozzle changes.

- Integrated chambers provide passive filament storage.

Return to top

Optimized Filament Feeding

The optimized filament feeding system enables instant detection of filament runout, ensuring successful prints.

- Detect filament runout to prevent print failures, saving time and materials.

- Continuous monitoring ensures uninterrupted high-quality print results.

- Reduce downtime with immediate alerts for filament issues.

Improved Extrusion

The redesigned extrusion box improves usability, easier assembly, disassembly, and simplified maintenance.

- Easier-to-use extrusion box with intuitive enhancements.

- Design changes simplify maintenance and troubleshooting.

- Streamlined design allows quick assembly and disassembly.

- Improved usability ensures consistent and reliable performance.

Enhanced Temperature Compensation

The latest firmware version provides more precise temperature control for your print bed, ensuring smooth prints with improved adhesion.

- Precise temperature control ensures smooth prints by maintaining optimal conditions.

- Stable temperature control minimizes the risk of warping, leading to more accurate prints.

- Improved temperature regulation provides consistent print outcomes across different projects.

- Reliable temperature control enhances the overall dependability of the printing process.

Automatic Filament Switching

The FlashForge Guider 3 Ultra can automatically switch to a new filament when the current spool runs out. Seamless printing without interruption.

- Auto-switching spools ensure uninterrupted printing.

- Reduces downtime by eliminating manual filament changes.

- Prevents disruptions, maintaining print quality and consistency.

Size & Structure Saves Time

The FlashForge Guider 3 Ultra features a stable dual-extruder and CoreXY structure for exceptional industrial-grade performance. It can accommodate models up to 600mm in height, with dual Z-axis ball screws for high surface quality. With an acceleration of 20000 mm/s² and a printing speed of 500 mm/s, it operates continuously to minimize downtime. Its innovative raft support system uses the same material as the model, simplifying support removal and reducing the number of extruder switches.

- Stable dual-extruder ensures precise nozzle switching for industrial-grade performance.

- The CoreXY Structure enhances precision with high rigidity and independently controlled axes.

- The vast capacity supports large-scale models with a maximum print height of 600mm.

- Efficient raft support saves time with seamless support removal and reduced extruder switching.

Return to top

Material Application Comparisons

| PPA-CF | PAHT-CF | PETG-CF |

|---|---|---|

| Size: 247 x 225 x 580 mm | Size: 188 x 123 x 471 mm | Size: 314 x 325 x 349 mm |

| Weight: 855 g | Weight: 732 g | Weight: 835 g |

|

Printing Time: 61 hours |

Printing Time: 15 hours, 12 minutes | Printing Time: 103 hours |

|

Challenge: Creating customizable, lightweight, and durable automotive fixtures with high strength and precision (±0.2 mm) to meet specific inspection needs. |

Challenge: Traditional subtractive manufacturing results in material waste, high costs, and long processing times. |

Challenge: Verify structural designs and test operation processes, offering high strength and resistance to deformation for outdoor use in high-temperature environments. |

|

Solution: The Guider 3 Ultra integrates 3D printing to merge parts into a single piece using PPA-CF for high strength and precision, achieving an 85% reduction in production time, a 25x increase in inspection speed, and over 90% in overall cost savings. |

Solution: The Guider 3 Ultra utilizes 3D printing technology with Black PAHT-CF for high strength and temperature resistance, eliminating material waste, reducing costs, shortening production cycles, and cutting printing time by 70% with valve layer support printing. |

Solution: The Guider 3 Ultra uses PETG-CF with 10% chopped carbon fiber for a high strength-to-weight ratio, offering lightweight durability, overcoming limitations of traditional and SLA methods, and providing excellent mechanical properties for outdoor and high-temperature applications. |

|

Result: A lightweight, durable, and cost-effective inspection fixture that meets stringent automotive requirements. |

Result: A cost-effective, high-performance prototype that meets rigorous aerospace requirements. |

Result: A robust, lightweight prototype that meets rigorous testing requirements, enabling efficient design verification and operational testing. |

Choosing between the Flashforge Guider 3 Printer options

| Guider 3 | Guider 3 Plus | Guider 3 Ultra | |

|---|---|---|---|

| Build Volume | 300 x 250 x 340 mm | 350 x 350 x 600 mm | 330 x 330 x 600 mm |

| Print Speed | 250 mm/s sprint speed | 250 mm/s print speed and under 50 dB noise level | 500 mm/s print speed, Up to 20,000 mm/s² acceleration, Quiet operation |

| Max Build plate temperature |

110°C |

120°C | 120°C |

| Max Extruder Temperature | 320°C | 320°C | 350°C |

| Number of Extruders | Single Extruder | Single Extruder | Dual Extruder |

Return to top

Technical Specifications

Printing

| Printing Precision | ±0.15mm or 0.002mm/mm |

| Position Precision | X/Y axis: 0.011 mm; Z axis; 0.0025 mm |

| Layer Thickness | 0.05-0.4mm |

| Build Volume | 330(L) x 330(W) x 600(H) mm |

| Nozzle Diameter | 0.4 mm Standard (Optional 0.6 mm/0.8 mm) |

| Maximum Extruder Temperature | 350°C (608°F) |

| Adjustable Heated Build Plate Temperature | Up to 110°C (230°F) |

| Filament Diameter | 1.75 mm |

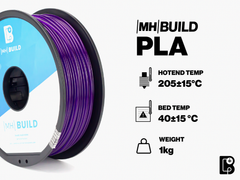

| Filament Compatibility | PA-CF, PA-GF, PETG-CF, PETG-GF, PA, PC, ABS, ASA, HIPS, PLA-CF, PETG, PLA |

| Print Speed | 10-500 mm/s |

Mechanical & Dimensions

| Number of Extruders | One |

| Printer Dimensions | 496 (L) x 436 (W) x 696 (H) mm (19.5 x 17 x 27 in) |

| Packaging Dimensions | 585 (L) x 530 W) x 760 (H) mm (23 x 21 x 30 in) |

| Net Weight | 60 LBS (27 KG) |

Electrical

| Power Supply | AC100-240V / DC24V / 20.8A, 650W |

| HD Touch Screen | 4.3 inch |

| Connectivity | USB Cable, USB Stick, Wi-Fi, Ethernet |

|

Certification |

CE / FCC / RoHS |

Software

| Software | FlashPrint |

| Compatible Slicing Software |

|

| File Input Format | STL / 3MF / OBJ / FPP / BMP / PNG / JPEG |

| File Output Format | GX / G / gcode |

|

Supports (OS) |

Windows XP/Vista/7/8/10, and Mac OS |