Formlabs Formlabs Form 4B Medical Basic Package

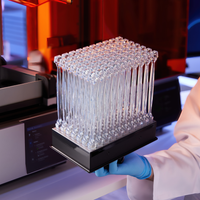

The Form 4B mSLA 3D Printer quickly produces medical-grade parts using Low Force Display™ technology. Its streamlined workflow, fast resin handling, and wide biocompatible materials library enable consistent, high-quality prints—often in under two hours—making it ideal for rapid medical prototyping and production.

- Blazing-fast prints in under two hours

- Wide range of biocompatible materials

- Consistent results with Low Force Display technology

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

| Jump To: | |||

|---|---|---|---|

| • Description | • Features | • What's Included | • Compare Models |

| • Tech Specs | • Compare Tech | • Resources | • FAQ |

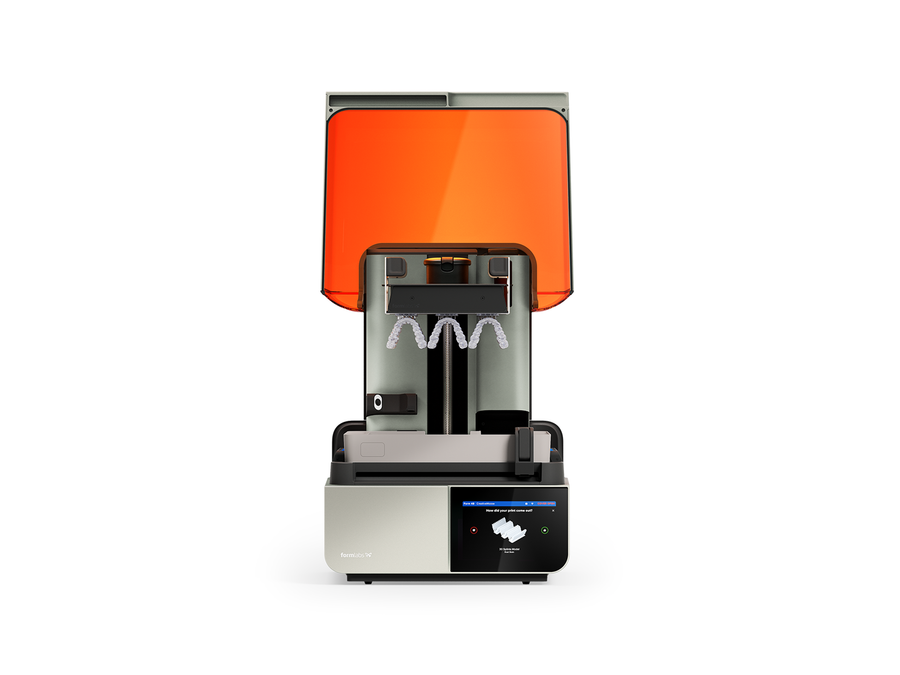

Form 4B mSLA 3D Printer

Medical Parts at Lightning Speeds

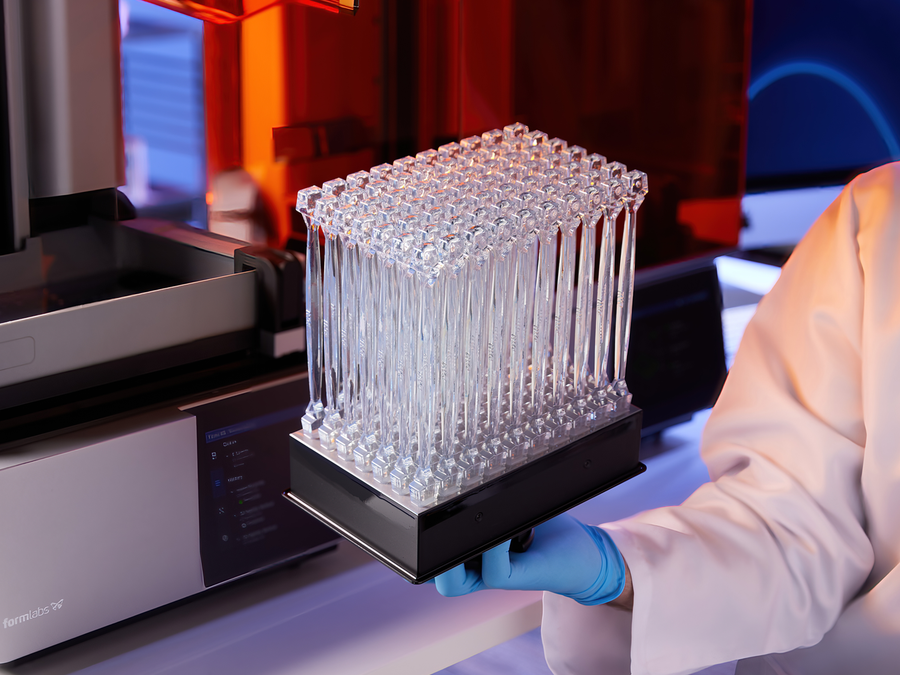

Quickly output biocompatible parts with the Form 4B masked SLA 3D printer. Using a customized print engine trademarked as Low Force Display™ (LFD), Formlabs once again develops a unique resin additive manufacturing system that is reliably capable of blazing-fast production without compromising a materials' quality and performance.

Key Features of the Formlabs Form 4B 3D Printer:

- Access Formlabs' Biocompatible materials library

- Print most parts in less than 2 hours

- Reliably consistent, high-quality prints

- Utilize reliable Low Force Display technology

- Compatible w/ Formlabs' industry-leading materials

- Seamless workflow with Form 4 ecosystem

- Expert access available with Medical Service Plan

- Build Volume: 200×125×210mm (7.9"×4.9"×8.3")

SWIFT PRINT SPEEDS

Achieve same-day resin 3D printing production with the Formlabs Form 4. When fast turnarounds are a top priority, a printer capable of swiftly outputting most prints in less than 2 hours is a must for your project workflow.

- Max Print Speed: 100mm/hr

- Avg Print Speed: 40mm/hr

- Fast Resin Heater

- Fast Resin Dispenser

LOW FORCE FOR HIGH PERFORMANCE

The Form 4B achieves fantastic print quality and performance thanks to its trademark technology—Low Force Display (LFD). Six hardware systems customized by Formlabs are combined to set the new standard for balancing lightning print speed with unmatched print quality reliability and material performance.

- Backlight Unit - 60 LED's emit powerful light through collimating lenses

- Light passes through 4K LCD masked to form layer shape

- Release texture and flexible tank work together to reduce peel force

- Onboard control sensors work together to ensure your printer operates in successful conditions

- Automatic resin dispenser keeps up with quick production

RELIABLE MATERIALS FOR VERSATILE APPLICATIONS

Print Formlabs' industry-leading materials for use in any industry on the Form 4B. It's compatible with many of Formlabs well-known formulas like High Temp, Silicone 40A, BioMed, and more with bonus Form 4 series exclusives such as...

- Fast Model V1

- Grey V5

- White V5

- Clear V5

- Black V5

LESS STRUGGLING, MORE PRINTING

Not only is the setup intuitive but each step of the resin 3D printing workflow on the Formlabs Form 4B is designed to be accessible for any printer operator on every print job. Seamlessly go from prep to print to process and efficiently use your limited time patients and printing rather than struggling.

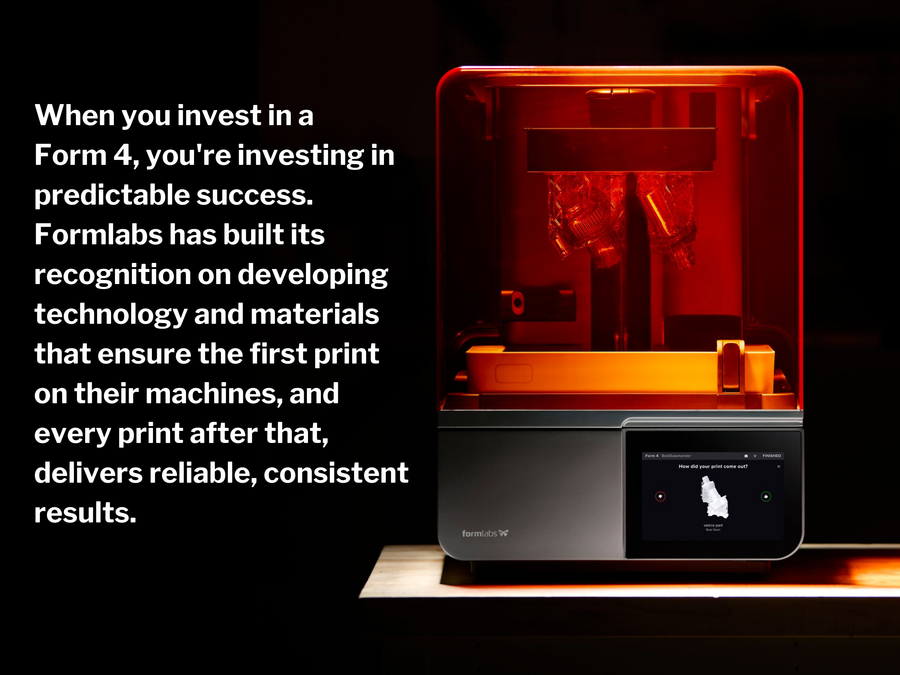

INDUSTRY-LEADING CONSISTENCY

When you invest in a Form 4, you're investing in predictable success. Formlabs has built its recognition on developing technology and materials that ensure the first print on their machines, and every print after that, delivers reliable, consistent results via the following:

- Validate print settings by engineers

- Measure & maintain Form 4 via 6 intelligent systems

- Every Form 4 is calibrated and inspected before shipping

- Avg lifetime of +75K layers with any Formlabs materials

MEDICAL PROS AT YOUR SERVICE

When high uptimes and urgent medical responses are top priorities, access to dedicated phone support, training, and more is crucial. Enter the Formlabs Medical Pro Service Plan, designed to get you the most out of your Form 4B 3D printer by connecting you with a dedicated team of certified medical 3D printing support representatives. Extend your coverage further with the following:

- Expedited replacement during servicing

- Direct 1-on-1 phone support w/ medical printing expert

- 90-minute live customized training

- Priority email support

- Customize—extend warranty up to 3 years

WHY BUY FROM MATTERHACKERS

MatterHackers is where digital fabrication technology meets passion. When you shop here, feel confident knowing that the vast selection of machines, materials, and accessories we've curated in our catalog are guaranteed top-quality products backed by our team of experts. Exceptional customer service, fast & free shipping on orders over $35, a 30-day return policy, and more make us the reliable go-to for professionals, educators, and hobbyists. At MatterHackers, we're more than just a retailer; we're your trusted partner in innovation.

- Diverse, expert-curated catalog

- Top-notch customer service

- Convenient fast & free shipping

- Training and Maintenance Services

- 30-day Returns

- Rewards Program on qualified purchases

What's Included with the Formlabs Form 4B Medical Packages?

| Basic Medical | Complete Medical | Premium Medical |

| $7,699 | $12,006 | $14,294 |

| 1 × Form 4B 3D Printer | 1 × Form 4B 3D Printer | 1 × Form 4B 3D Printer |

| 1 × Form 4 Resin Tank | 1 × Form 4 Resin Tank | 1 × Form 4 Resin Tank |

| 1 × Form 4 Mixer | 1 × Form 4 Mixer | 1 × Form 4 Mixer |

| 1 × Form 4 Finish Kit | 1 × Form 4 Finish Kit | 1 × Form 4 Finish Kit |

| 1 × Form 4 Build Platform Flex | 1 × Form 4 Build Platform Flex | 2 × Form 4 Build Platform Flex |

| Open Material Mode | 1 × Form Wash (Gen 2) | 2 × Form Wash (Gen 2) |

| 1 × Solvent Pump | 1 × Solvent Pump | |

| 1 × Form Cure (Gen 2) | 1 × Form Cure (Gen 2) | |

| Open Material Mode | Open Material Mode | |

| 3 Year Medical Service Plan | 5 Year Medical Service Plan |

What are the Differences Between the Formlabs Form 3+, Form 3L, and Form 4?

| Model | Form 3+ | Form 3L | Form 4 |

| Price | $2,499.00 | $5,999.00 | $3,499.00 |

| Technology | Low Force Stereolithography |

Low Force Stereolithography |

Low Force Display |

| Ideal Application(s) | ✔ Fully Automated Throughput ✔ Quick laser-based SLA Production ✔ Small to Medium Scale Prototyping |

✔ Large-scale Prototyping |

✔ Blazing Fast Throughput ✔ Small to Medium Scale Prototyping |

| Build Volume (W × D × H) |

145×145×193mm (5.7"×5.7"×7.6") |

335×200×320mm (13.2"×7.9"×12.6") |

200×125×210mm (7.9" x 4.9" x 8.3") |

| Printer Dimensions (W × D × H) |

405×375×530mm (15.9"×14.8"×20.9") |

770×520×740mm (30.3"×20.5"×29.1") |

398×367×554mm (15.7"×14.5"×21.9") |

| Weight | 17.5kg (38.5lb) | 54.4kg (120lb) | 18.3kg (40.4lbs) |

| Light Source | One 250 mW laser | Two 250 mW laser | 60 LED's |

| XY Resolution | 25 microns | 25 microns | 50 microns |

| Layer Thickness* | 25 - 300 microns (.001" – .012") |

25 - 300 microns (.001" – .012")** |

25 - 300 microns (.001" – .012") |

| Resin Cartridges | 1 | 2 | 1 |

| Open Platform Materials |

Yes (License Coming Soon) |

Yes (License Coming Soon) |

License ETA TBD |

| 24/7 Printing Capabilities | Optional - Form Auto | No | No |

** The Form 3L is capable of printing at 25 micron layer heights, but only one 25 micron print setting is available for Formlabs' large format 3D printers.

What are the Technical Specifications of the Form 4B 3D Printer?

| GENERAL | |

|---|---|

| Machine | Resin 3D Printer |

| Technology | Low Force Display (LFD)™ / mSLA |

| Light Source | LED's |

| Assembly | Fully-Assembled |

| Machine Dimensions (W × D × H) |

398mm×367mm×554mm (15.7"×14.5"×21.9") |

| Weight | 18.3kg (40.4lb) |

| PRINTER PARAMETERS | |

| Build Volume (W × D × H) |

200m×125mm×210mm (7.9" x 4.9" x 8.3") |

| XY Resolution | 50 microns |

| Layer Thickness | 25 - 300 microns (.001" – .012") |

| Light Source Specifications | 1 Light Processing Unit (LPU); LPU 4 uses a high-resolution LCD to mask powerful, uniform projection of light coming from the Backlight Unit (60 LED's on a PCB emitting light through collimating lenses) |

| PRINTER FEATURES | |

| Resin Cartridges | 1 |

| Automatic Resin Dispenser | Yes |

| Built-In Camera | Yes; can be turned off, covered, or removed |

| Print Monitoring | ✔ |

| Resin Level Sensor | ✔ |

| Resin Temperature Sensor | ✔ |

| Printer Leveling Sensor | ✔ |

| Mixer Debris Sensor | ✔ |

| [Print] Force Sensor | ✔ |

| MATERIAL COMPATIBILITY | |

| Formlabs Materials | General Purpose Resin(s) Black V5, Clear V5, Grey V5, White V5, Fast Model V1, PRecision Model, Color Base Tough & Durable Resin(s) Durable, Tough 1500, Tough 2000 Rigid Resin(s) Rigid 4000, Rigid 10K Engineering Resin(s) ESD, Flame Retardant, High Temp, Silicone 40A V1, Alumina 4N V1 Flexible & Elastic Resin(s) Elastic 50A Resin V2, Flexible 80A Jewelry Resin(s) Castable Wax, Castable Wax 40 |

| Biocompatible | Yes; BioMed Durable, BioMed Flex 80A, BioMed Elastic 50A, BioMed Clear, BioMed Amber, BioMed Black, BioMed White |

| Open Platform | Access to PreForm Print Settings Editor coming soon Open Material License required, ETA TBD |

| SOFTWARE | |

| Compatible Program(s) | PreForm |

| OS Compatibility | Windows 7 (64-bit) and up Mac OS X 10.12 and up |

| Additional System Requirements |

OpenGL 2.1 C++ runtime library from Microsoft (Windows only) 4GB RAM (8GB recommended) |

| Supported Input File Type(s) | STL, OBJ, and 3MF |

| Supported Output File Type(s) | FORM |

| Print Setup Features | One-Click Print, Remote Print Rotate, scale, duplicate, and mirror Auto-mesh repair, Auto-generation of supports Auto-orient for optimal print position Adaptive layer thickness for faster printing with fine details Layer slicer for path inspection Available in multiple languages |

| Dashboard Printer Management Features |

Manage prints and printers via the cloud Track resin and tank usage over time SMS and email alerts Create enterprise group accounts with admins to more easily share printers and control access |

| WARRANTY | |

| Warranty Period | 1 Year if purchasing the 2 Year Pro Service Plan, 2 Years if purchasing the 3 Year Pro Service Plan, 3 Years |

What's Different Between SLA and SLS on Formlabs Machines?

| Model(s) | Form 3+ / Form 3L / Form 4 | Fuse 1 / Fuse 1+ |

| Starting Price | $2,499 / $5,999 / $4,499 | $23,499 / $33,489 |

| Technology | Stereolithography Laser-based - Form 3+ / 3L LCD-based - Form 4 |

Selective Laser Sintering (SLS) |

| Pros | Great value High accuracy Smooth surface finish Range of applications |

Strong functional parts Design freedom (no supports) Simpler post-processing |

| Application(s) | Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Modelmaking |

Functional prototyping Short-run, bridge, or custom manufacturing |

| Maximum Part Size (W × D × H) |

335mm × 200mm × 320mm (13.2" × 7.9" × 12.6") (Form 3L) |

159mm × 159mm × 295mm (6.3" x 6.3" x 11.6") (Nylon 12 Powder) |

| Max Printer Dimensions (W × D × H) |

405mm × 375mm × 530mm (15.9" × 14.8" × 20.9") (Form 3L) |

770mm × 520mm × 740mm (30.3" × 20.5" × 29.1") |

| Machine Form Factor | Desktop | Benchtop / Free-standing |

| Compatible Facility | Office Workshop |

Workshop |

| Printing Environment | Ambient conditions. Only PU Resins require a dry cabinet for humidity control. |

Air environment, with the option to print in a nitrogen atmosphere for enhanced material properties and lower refresh rates. |

| Material Type | Resin | Powder |

| Materials | 20+ functional resins for prototyping and producing end use parts |

6 high-performance industrial- grade materials, including nylon 11, nylon 12, TPU, polypropylene, and glass & carbon-filled nylon composites |

| Biocompatible Materials | Available on the "B" version | Yes |

| Layer Thickness | 25 - 300 microns (.001" – .012")* |

110 microns (0.004") |

| Resolution | ★★★★★ | ★★★★☆ |

| Accuracy | ★★★★★ | ★★★★★ |

| Surface Finish | ★★★★★ | ★★★★☆ |

| Supports | Auto-generated Light-touch removal |

None required |

| Throughput | ★★★★☆ | ★★★★★ |

| Output | Excellent (3+ / 3L) Superior (4) |

Excellent |

| Ease of Use | ★★★★★ | ★★★★☆ |

| Training | Minor training on build setup, maintenance, machine operation, and finishing. Plug and play. |

Moderate training on build setup, maintenance, machine operation, and finishing. |

| Training Included | Optional | Yes; more options available |

| Ancillary Equipment | Washing station Post-curing station Finishing tools |

Post-processing station (part cleaning & material recovery) |

* Layer Thickness varies based on materials when resin 3D printing.

What Resources are Available for the Form 4 3D Printer?

FAQ

Why should someone buy a Form 4B?

To print with any of Formlabs' 14 biocompatible materials. Form 4B is mainly targeted towards dental and medical users.

Can I upgrade from a Form 4 to a Form 4B in the field if I find that I need a biocompatible material in the future?

No. Customers need to purchase a Form 4B to use biocompatible materials.

How do I purchase, setup, and use a Form 4B?

Purchase one of the Medical printer packages. During printer onboarding, you will be prompted to temporarily connect to your printer to the internet. Once connected, the printer will silently download a software license and transform itself into a Form 4B. If they don’t connect, the printer will remain a Form 4. Once the printer transforms to a Form 4B, the top bar on the Touch UI will become blue and say “Form 4B”. Now you can print with Formlabs' 14 biocompatible materials.

What happens if I order a Form 4B but do not connect to the internet?

You will not be able to print with Formlabs' biocompatible materials. PreForm and the printer will explain the error and ask you to connect to the internet. Keep in mind that you are able to hotspot from a cell phone.

Is the Medical Service Plan (MSP) required with the Form 4B?

Yes, similar to the Form 3B, the Medical Service Plan is mandatory. The MSP provides you with unlimited access to a dedicated Medical Service Team, and also includes replacement parts and a hot swap free of charge, which means that if there is an issue with your printer that can’t be resolved remotely or with replacement parts, a replacement printer will be sent to you in order to minimize your downtime.

Does the Light Processing Unit (LPU) need to be replaced frequently?

No. The LPU is a long-lasting consumable tested to deliver consistent print performance throughout its lifetime. The LPU 4 has an expected lifetime of 600k - 2.7M layers, depending on the material and layer height printed.

Why does Form 4 use 4K resolution, not 8K or 12K?

Form 4 uses a 50um pixel size, highly collimated light, and advanced pixel smoothing to produce razor-sharp detail and smooth surfaces. The number of pixels is only one small factor for producing great parts. Based on internal testing and beta feedback, the Form 4 is expected to deliver the same print quality as printers with a higher resolution LCD.

How does the peel force on the Form 4 compare to the Form 3?

Formlabs developed a specialized print engine and resin tanks to minimize peel forces. This allows the Form 4 tanks to last longer, the prints run faster, and the parts look better.

Can I use my Form Wash (1st generation) with Form 4?

Yes, you can remove the parts from the Form 4/B build platform and use your existing Form Wash. However, the Form Wash (2nd Generation) is required to fit the new Form 4 build platform has a larger build area (and therefore larger

build volume). The maximum part size that can fit in the legacy Form Wash is 145mm × 145mm × 175mm.

Form Wash (2nd Generation) also has 3x more agitation and improved longevity allowing you to wash 67% more parts before

replacing your solvent.

Do Form 3 cartridges, resin tanks, and build platforms work on Form 4?

No. The cartridge, resin tank, and build platform have been redesigned to achieve significantly better performance, lifetime, and cost for the Form 4. To make those improvements, it wasn’t possible to make Form 4 printers backwards compatible with Form 3 series consumables.

Do Form 4 cartridges, resin tanks, and build platforms work on Form 3?

No. Improvements to these consumables are possible exclusively to the Form 4.

What makes the new Form 4 Resins specific to the printer?

The new print engine on Form 4 is vastly different from Form 3, so the new formulations were designed to take advantage of the new mSLA hardware.

How does Tank lifetime vary per material – do we have the same aggressive, moderately aggressive and not aggressive categories for different materials?

Tank lifetime is now the same for all materials. The tank design has been updated and is no longer degraded by the components present in some of Formlabs' resins.

Does Form Auto work with Form 4?

No, it is only available for Form 3 series. printers. While 24/7 automation is not available at this time, Form 4/B is still a great option for customers with high throughput applications, offering higher throughput and lower cost per part than Form 3 and other solutions on the market.

Does the Resin Pumping System work with Form 4/B?

No.

My tallest parts (or the number of parts per job) I printed on my Formlabs Form 4 don’t fit on the current Form Cure. What can I do?

At this time, it is recommended to use Form Cure L to cure parts printed on your Form 4 if the part or number of parts don't fit in the Form Cure.

Will the Formlabs Form 4/B be open or closed in terms of third-party materials?

Formlabs will ultimately bringing their SLA Open Platform to Form 4/B, including: Certified materials, Print Settings Editor, and Open Material License. They'lll start by adding Form 4/B to the PreForm Print Settings Editor late May 2024. Open Materials License to come.

Can I turn off or remove the camera on the Formlabs Form 4?

Yes. There are a few options for disabling the camera depending on your requirements.

- Disable the camera using the Touch UI.

- Physically cover the camera with a 3D printed part (STL file coming soon) or any other cover.

- Physically remove the camera from the printer. This is a 5-10 minute service loop. A simple guide is being prepared by Formlabs for any customer who wants to do this.

Can I use the printer offline?

Yes, Form 4 can be used offline. For Form 4B, you will need to connect to the internet at least once to activate the capability of printing with Formlabs' biocompatible resins.

Do I need to buy a Form 4 Mixer for each Resin Tank?

For convenience, it is recommended to have 1 mixer for every different type of material you intend to print with. Otherwise, you will need to wash the Mixer in IPA using Form Wash before every material switch.

- Ex: If you plan to print Grey v5 and Tough 2000 resins on a single Form 4 3D printer, having two resin tanks and two mixers on hand is recommended for the fastest and easiest workflow.

What is the lifetime of the Form 4 Mixer?

You can use a Form 4 Mixer indefinitely.

Is Form 4 TAA compliant?

Contact support@matterhackers.com to ask about the TAA compliant version of the Formlabs Form 4.

How often should I be inspecting my resin tank?

Form 4 resin tanks should be inspected monthly.

How can I tell my resin tank is past its lifetime?

Replace a Form 4/B resin tank as soon as you notice:

- Punctures, cuts, wrinkles, or gouges in the film

- Wear on the film that begins to affect print quality or reliability.

- Repeatedly printing

the same model in the same location on a tank can cause the tank film to wear more

quickly.

- Repeatedly printing

Do Form 4/B printers have built in tank usage monitoring?

Yes. You can check how many layers, prints, and liters have been printed on a resin tank at any time.

- When a tank reaches >=75,000 layers and is inserted into a printer, the printer will prompt you to inspect the tank and consider replacing it.