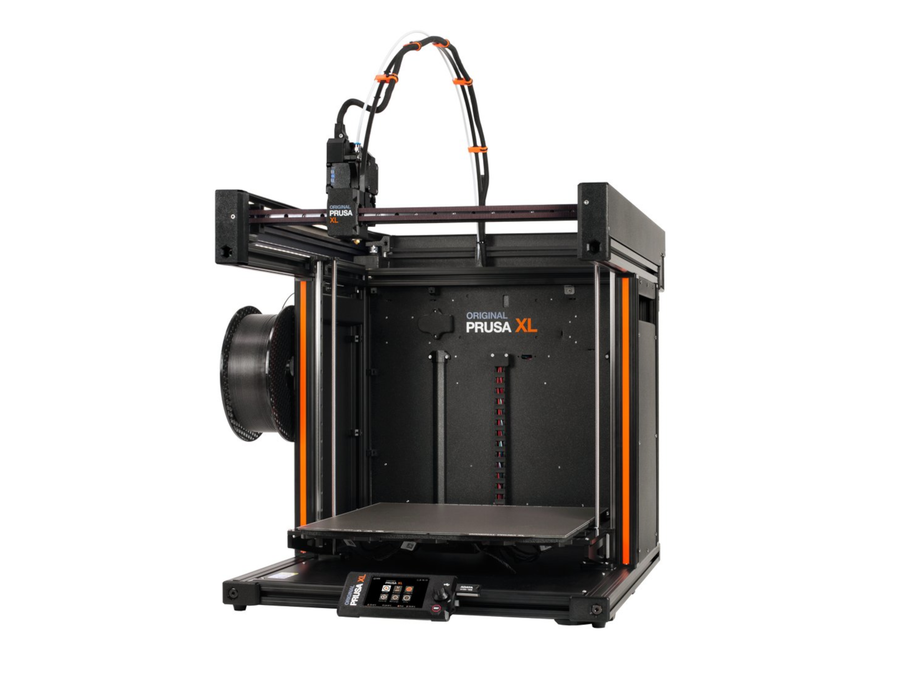

Prusa Research Original Prusa XL 3D Printer

The Original Prusa XL 2025 is a large-format 3D printer with a 360×360×360 mm build volume designed for efficient multi-material production. It features a toolchanger handling up to 5 toolheads and a segmented heatbed that enables zero-waste, wipe-to-infill printing.

- Maximize build volume for big projects

- Accelerate printing with five toolheads

- Eliminate waste with wipe-to-infill printing

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Shop with confidence at MatterHackers – the price you see is the price you pay, with no unexpected tariffs or duties at checkout!

Notice for DoD & Government Customers:

This product ships from an international warehouse. If you are ordering on behalf of a government or military organization, please contact the MatterHackers Sales team at sales@matterhackers.com to discuss delivery requirements prior to placing your order. Additional coordination may be required to ensure successful delivery.

Original Prusa XL 3D Printer

High-Speed, Multi-Material, Large-Format 3D Printing

The Original Prusa XL 2025 is a groundbreaking large-format 3D printer designed for high-speed, multi-material printing with minimal waste. Featuring a state-of-the-art toolchanger capable of handling up to five independent toolheads, this printer enables seamless multi-material and multi-color prints without the hassle of traditional nozzle purging. Its segmented heatbed ensures precise, edge-to-edge printing while optimizing energy efficiency. With advanced features like Input Shaper, Pressure Advance, and Spool Join, the XL delivers superior print quality at record speeds. Built with open-source principles, it supports a wide range of filaments, making it an ideal choice for professionals, hobbyists, and manufacturers alike.

Key Features of the Original Prusa XL 3D Printer:

- Large Build Volume: 360×360×360 mm for big projects

- Advanced Toolchanger: Up to five toolheads for multi-material printing

- Zero-Waste Printing: Eliminates filament waste with wipe-to-infill options

- High-Speed Performance: Input Shaper & Pressure Advance for fast, precise prints

- Smart Connectivity: Wi-Fi, Ethernet, and Prusa Connect for remote printing

Zero-Waste Printing

The XL is designed to minimize filament waste while maintaining efficient multi-material printing, making it a cost-effective solution for 3D printing enthusiasts. Unlike traditional single-extruder printers that generate excessive waste during material changes, the XL optimizes filament use with innovative features like wipe-to-infill printing and minimal priming towers.

- The XL reduces filament waste significantly compared to standard single-extruder 3D printers.

- With proper filament drying and wipe-to-infill settings, it can print with virtually zero waste.

- No need for wipe towers or excess purging, keeping the print area clean and efficient.

Combine Materials

The XL's individual toolheads allow seamless integration of multiple materials in a single print, enabling greater design flexibility and cost efficiency. Whether blending flexible filaments with rigid ones or using affordable materials for support structures, the XL makes multi-material printing more accessible and economical.

- Easily combine different materials, such as Flex with PETG or PLA for removable supports.

- Reduce costs by using lower-cost materials for support structures in high-performance prints.

- Achieve complex, multi-material prints with minimal effort and maximum efficiency.

Fastest Multi-Material Printer

The Original Prusa XL is engineered for speed, utilizing its lightning-fast toolchanger, Input Shaper, and Pressure Advance technologies to deliver multi-material prints faster than any competitor. It achieves this speed without sacrificing the premium print quality that has made the award-winning MK4 a favorite among professionals and hobbyists alike.

- Prints multi-material projects faster than any other desktop 3D printer.

- Maintains the same high-quality results as the MK4, even at high speeds.

- Utilizes advanced motion control technologies for smoother, more precise prints.

XL Toolchanger

The heart of the Original Prusa XL is its innovative toolchanger, allowing up to five materials to be loaded simultaneously for fast, efficient multi-material printing. Unlike traditional filament-swapping methods, the XL instantly swaps toolheads, eliminating long material changeovers and boosting reliability. With the ability to load up to five 2kg spools, users can print massive 10kg objects without interruption.

- Swap between up to five toolheads instantly for faster multi-material prints.

- No long filament change procedures—each nozzle is always ready to print.

- Supports large-scale prints with up to 10kg of filament loaded at once.

Keep on Printing with Spool Join

Spool Join ensures uninterrupted printing by automatically switching to a new spool when one runs out, eliminating the risk of a failed print due to an empty filament roll. This feature is perfect for utilizing partially used spools and enabling large, continuous prints without manual intervention. Load up to five 2kg spools, activate Spool Join, and let the printer handle the rest.

- Automatically switches to a new spool when filament runs out.

- Perfect for finishing off partially used spools and reducing waste.

- Enables uninterrupted large-scale printing with up to 10kg of material.

Exceptional Print Quality and Reliability

Speed means nothing without precision, and the Original Prusa XL delivers both with uncompromising quality. Featuring the advanced Nextruder system, it produces flawless prints with impressive overhang capabilities and superior handling of flexible filaments. Every part is printed with exceptional detail, ensuring seamless fit and function.

- Achieves outstanding print quality even at high speeds.

- Handles steep overhangs up to 15° and flexible filaments with ease.

- Prints parts with precision to ensure a perfect fit every time.

High-Speed Printing

When time is critical, the Original Prusa XL rises to the challenge with cutting-edge speed enhancements. Utilizing native Input Shaper and Pressure Advance implementations, the XL significantly reduces print times while maintaining excellent quality. Whether you're printing prototypes or production parts, the XL delivers results faster than any other multi-material printer in its class.

- Features Input Shaper and Pressure Advance for ultra-fast, high-quality prints.

- Reduces print times significantly without sacrificing precision.

- The fastest multi-material desktop printer available today.

Beautifully Quiet

With Phase Stepping technology, the XL automatically fine-tunes its motor response for ultra-quiet operation. Despite its speed, the XL remains silent, allowing you to work without distractions, and Stealth Mode makes it even quieter.

- Advanced motor control ensures minimal noise.

- Perfect for quiet environments like offices and workspaces.

- Stealth Mode further reduces operational sound.

Easy to Use

Automatic calibration, one-click printing, and a flawless first layer make the XL effortless to operate. Say goodbye to manual adjustments and material shortages—the XL simplifies every step of the printing process.

- No need to manually adjust the nozzle or print bed.

- Built-in material monitoring prevents mid-print failures.

- Includes a detailed handbook for seamless multi-material printing.

Perfect First Layer Out of the Box

The XL delivers a flawless first layer on every print, eliminating the need for manual adjustments. Its Loadcell sensor accurately measures offsets, ensuring perfection on any print surface.

- No manual Z adjustments or leveling screws required.

- Works on all surface textures, including reflective and textured sheets.

- The sensor operates with unmatched precision, independent of visual data.

Tackle Any Type of Filament

From PLA and PETG to ASA and carbon-filled filaments, the XL prints a vast range of materials—including flexible filaments—with ease. Its direct drive Nextruder simplifies flexible material printing, while the optional enclosure supports more advanced filaments.

- Direct drive Nextruder enhances flexible filament printing.

- Compatible with a wide variety of standard and engineering-grade materials.

- Enclosure available for advanced materials requiring temperature stability.

Wi-Fi and Prusa Connect

The Original Prusa XL supports wired and wireless connectivity, allowing you to manage prints remotely via the secure Prusa Connect system. Upload a G-code and start printing in seconds.

- Control your printer from anywhere via encrypted Prusa Connect.

- Schedule and monitor prints remotely, even with a webcam.

- Supports both wired LAN and Wi-Fi connections for flexibility.

Color LCD Touch Screen

Operate the XL your way—using either the intuitive touchscreen or the tactile knob for precise control. The color LCD screen offers easy navigation, G-code previews, and advanced features.

- Choose between touchscreen control or a physical knob.

- Access G-code previews, QR codes, and Cancel Object functionality.

- User-friendly interface simplifies operation and troubleshooting.

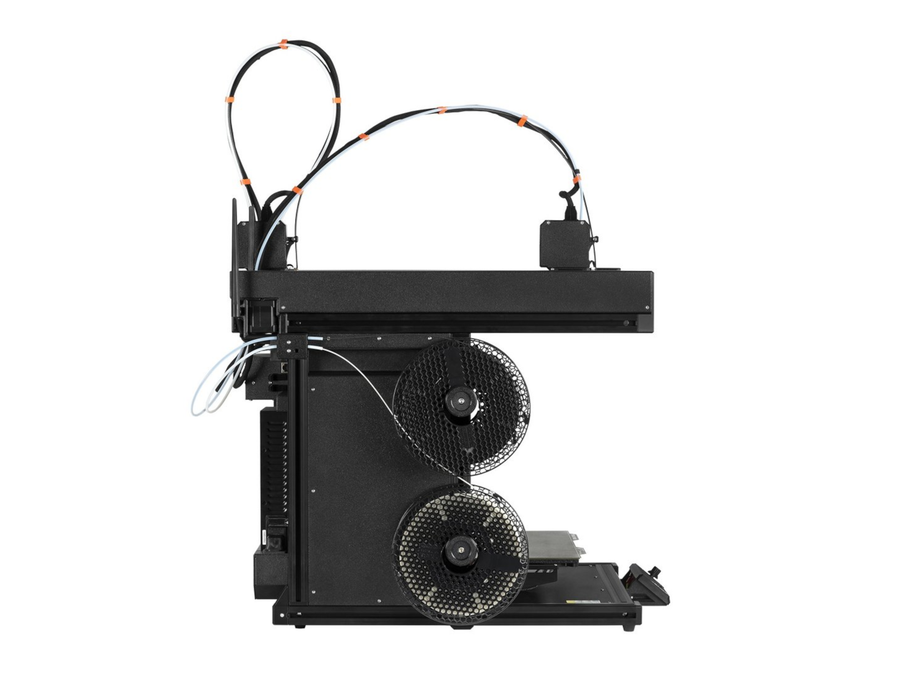

Unique Segmented Heatbed

The XL’s segmented heatbed consists of 16 independently controlled tiles, preventing warping and ensuring uniform heating. The modular design also allows for energy-efficient operation.

- Individual heatbed segments minimize thermal distortion.

- Proven double-sided print sheets optimize adhesion.

- Unused segments can be switched off to save power.

Power-Loss Recovery

The XL protects your prints from unexpected power failures with hardware-based power-loss recovery. If an outage occurs, the printer resumes exactly where it left off.

- Saves extruder position during power failures.

- Seamlessly resumes prints upon power restoration.

- Works even for network-initiated prints.

Actively Updated

Prusa continually releases firmware updates that introduce new features and optimizations. Even years after launch, the XL remains at the cutting edge of 3D printing.

- Regular firmware updates enhance performance and capabilities.

- Long-term support ensures your printer stays up to date.

- Past models have received major updates even years after release.

Designed for Offline Use

The XL is fully functional without an internet connection, offering complete offline control. There are no mandatory network requirements or limitations.

- Operate the printer without requiring internet access.

- No forced connectivity ensures privacy and security.

- All features work natively offline.

Multi-Material Supports – Perfect Surface

Combine PLA and PETG for cost-effective, easily removable supports, achieving a flawless surface finish.

- PLA supports peel off PETG easily, eliminating post-processing hassle.

- Reduces material costs compared to soluble supports.

- Ideal for achieving smooth, professional-looking prints.

Multi-Material Supports – Perfect Surface

Combine PLA and PETG for cost-effective, easily removable supports, achieving a flawless surface finish.

- PLA supports peel off PETG easily, eliminating post-processing hassle.

- Reduces material costs compared to soluble supports.

- Ideal for achieving smooth, professional-looking prints.

PCCF Screwdriver with PETG Infill

Optimize cost and performance by using premium PCCF filament for external layers and durable PETG for infill.

- Maintains the premium look of PCCF while reducing material costs.

- Ensures strong, functional prints.

- Ideal for high-performance tools and parts.

OPTIONS

Additional Toolheads

Upgrade your Original Prusa XL over time by adding more toolheads for multi-material and multi-color printing.

- Start with a single toolhead and expand as needed.

- Available upgrades include dual- and five-head configurations.

- Enables complex prints with different materials or colors.

XL Enclosure

The official enclosure stabilizes the printing environment, reduces noise, and supports advanced materials.

- Improves temperature stability for engineering-grade materials.

- Features an integrated filtration system for cleaner air.

- Not required for PLA, PETG, and similar materials.

WHAT'S INCLUDED?

- Original Prusa XL Semi-Assembled OR Assembled 3D Printer

+ Single, 2, or 5-Toolhead(s) (Depending on Selection) - Satin Powder-Coated Steel Sheet

- Prusament PLA Prusa Galaxy Black (1kg)

- Prusa Lubricant for Bearings

- Alcohol-Saturated Wipes & Acupuncture Needle

- Toolset: Uni-wrench, 13-16 wrench, Nose pliers, Allen and Torx keys

- USB Drive with Sample Prints (G-codes)

- 3D Printing Handbook

Warranty Note

Consumable parts, such as print sheets, are not covered under warranty due to expected wear over time, except in cases of manufacturing defects upon delivery. Cosmetic damage is also excluded.

TECHNICAL SPECIFICATIONS

Measurements

- Build Volume: 360×360×360 mm (14.17’’×14.17’’×14.17’’)

- Filament Diameter: 1.75 mm

- Layer Height: 0.05-0.30 mm

- Printer Dimensions: 700 mm (W) × 900 mm (H) × 720 mm (D) (27.5’’×35.5’’×28.5’’)

- Weight: 27.9 kg (single-tool), 29.3 kg (dual-head), 33.7 kg (five-head)

Electronics

- Mainboard: Custom 32-bit xBuddy electronics with STM32

- Stepper Drivers: Trinamic 2130

- Stepper Motors: 1.8°

Extruder

- Type: Nextruder, Direct Drive, E3D V6 compatible (with adapter)

- Filament Path: Aluminum heatsink, all-metal hotend

- Drive System: Planetary Gear System, 10:1 gearbox ratio

Nozzle

- Max Nozzle Temperature: 290 °C (554 °F)

- Max Heatbed Temperature: 120 °C (248 °F)

Controls

- LCD Screen: 3.5″ color touchscreen

- Connectivity: USB drive / LAN / Wi-Fi (via Prusa Connect)

Sensors

- Filament Sensor: Yes

- Loadcell Sensor: Yes

- Power Panic: Yes

- Thermistors: 4 high-precision Semitec thermistors

Print Surface

- Heatbed: Segmented with 16 independently controlled zones

- Build Plates: Removable magnetic steel sheets with various textures

Calibration

- Bed Leveling: Automatic Mesh Bed Leveling (only on print area)

Supported Materials

- Standard: PLA, PETG, Flex, PVA, PC, PP, CPE, PVB

- With Enclosure: ABS, ASA, HIPS, PA

Power

- PSU: 240W custom Delta PSU with Power Panic

- Consumption: PLA ~80W / ABS ~120W