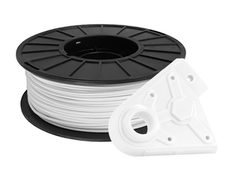

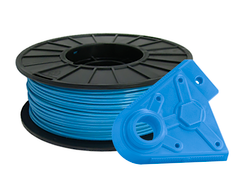

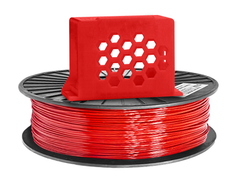

MatterHackers Silver PRO Series Tough PLA Filament - 1.75mm (1kg)

MatterHackers PRO Series Tough PLA 3D printing filament offers superior performance and reliability for designers and engineers. This advanced PLA material boasts higher impact resistance, heat tolerance, and excellent machinability, making it perfect for functional prototypes and end-use parts. By using Ingeo PLA 3D870, Tough PLA outperforms standard PLA in every way.

• Exceptional strength, akin to ABS

• Optimized for complex geometries

• Easily machinable and compatible with water soluble support

• Explore Wholesale Pricing and Bulk Purchases Here

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Achieve Unmatched Reliability with PRO Series Filament

Experience superior quality with MatterHackers PRO Series filament, designed to excel in any 3D printing project. When your 3D printed component's performance is of utmost importance, trust in a material that consistently delivers. Our PRO Series filament undergoes rigorous refinement and testing to ensure outstanding results across various applications. Our material experts have crafted a diverse array of high-performance thermoplastics, capable of maintaining dependability from initial prototyping stages to polished, end-use designs. With PRO Series filament, bring your envisioned parts to life with unwavering precision.

REMARKABLY TOUGH 3D PRINTING FILAMENT

PRO Series Tough PLA 3D printing filament is engineered to outperform standard PLA in every way. PRO Series Tough PLA consistently demonstrates a higher level of detail in 3D prints, exceptional first layer adhesion, improved adhesion between layers, and an overall reduction in warping, curling, and failed 3D prints. PRO Series Tough PLA is made using Ingeo PLA 3D870, creating the perfect material for engineers who create product-ready 3D printed parts on any scale.

PRO Series Tough PLA provides the strength of ABS filament, but it's easy to use like regular PLA

RELIABLE PRINTING FOR DESIGNERS AND ENGINEERS

With little to no warping or delamination, Tough PLA is more impact-resistant than standard PLA, and even has higher stiffness, making it a great choice for tooling and manufacturing aids. Tough PLA is optimized to work with PVA support material to create highly detailed parts with complex geometries. Model-making and printing large, functional parts has never been easier. Do not hesitate to print large or complex parts - Tough PLA is optimized for reliability when printing large scale parts without any enclosures or setting adjustments. Complex geometries for functional parts have never been easier because Tough PLA is compatible with water-soluble PVA support material.

PRINT COMPLEX PARTS WITH EASE

PRO Series Tough PLA is optimized for reliability when printing large scale parts without any enclosures or setting adjustments. Complex geometries for functional parts have never been easier because Tough PLA is compatible with water-soluble PVA support material.

PRO Series Tough PLA started as a basic PLA material. We then added Ingeo PLA 3D870 and engineered in advanced properties with the goal of creating functional and durable end-use 3D printed parts. The results were stunning - a fully functional PLA that's just as easy to print with as regular PLA, but with higher impact resistance and heat tolerance.

PRO Series Tough PLA and PVA support material is the perfect combination for 3D printing larger, complex prototypes.

A POWERFUL 3D PRINTING FILAMENT

Just like regular PLA, Tough PLA is easy to use - with little to no warping or delamination, successful printing is guaranteed - no matter how large or small the project.

This advanced PLA is perfect for designers or engineers that need to produce prototypes quickly and efficiently. Anyone can now use the reliability of PRO Series Tough PLA to ensure that their functional prints turn out just the way they are intended.

PRO Series Tough PLA 3D Printing filament is the go-to option of designers and engineers for creating functional 3D printed parts.

ULTIMATE MACHINING CAPABILITIES

PRO Series Tough PLA's advanced properties provide the ultimate experience for machining, tooling, and tapping. It's a versatile material that can be used in many settings, including creating custom jigs and fixtures. Don't hesitate to use Tough PLA for projects that require tapped threads and bolts - it can even be sanded and finished just as easily as regular PLA for presentation-ready parts.

PRO Series Tough PLA 3D printing filament is the best option for creating functional prototypes.

ANNEALING FOR MAXIMUM TOUGHNESS

While Tough PLA is already much stronger compared to regular PLA right off the printer, maximum strength and heat resistance can be achieved through the post-print annealing procedure. The easiest way to achieve this is by placing your print on a cookie sheet or other oven-safe surface and putting it in a conventional oven at a temperature range of 176-266°F (80-130°C) for 30-60 minutes. After this process is complete, carefully remove the print from the oven and allow it to cool back to room temperature.

PRO Series Tough PLA prints that have been annealed will demonstrate over 4 times the impact strength of standard PLA!

PROFESSIONAL QUALITY FILAMENT - SUCCESS GUARANTEED

MatterHackers PRO Series Filaments are engineered to highlight the strengths of each type of 3D printer filament. Manufactured to the tightest tolerances on the market and made in the USA, PRO Series Filaments include PLA, ABS, PETG, Nylon, Flex and now Tough PLA. So no matter what kind of 3D printing project you’re working on, MatterHackers has the filament to get it done.

Print with confidence thanks to the MatterHackers' Success Guarantee. We are passionate about helping you succeed in all your 3D printing endeavors. That's why if you're not satisfied, neither are we. Check out the Success Guarantee here.

PLA, aka Polylactic Acid, is a multipurpose material commonly used in 3D printing. PLA is a bioplastic, which means it is made from renewable natural resources such as corn starch and tapioca products. As a biodegradable material, it is much better for the environment, especially compared to petrochemical-based alternatives. This product is a 1 Kg (2.2 lbs) spool of PRO Series Tough PLA filament. All PRO Series filament is vacuum sealed with desiccant for storage and freshness.

Check out the whole line of MatterHackers PRO Series 3D printing materials.

Quality Assurance: Why Filament Diameter and Ovality Matters

With PRO Series materials, you know you’re getting the most accurate filament diameter and ovality available. Having a consistent diameter of 3D printing filament is very important - it directly impacts the print quality of your designs. The slicing engine calculates the volume of filament that will be deposited on each layer. The critical value that is input into the slicing engine for that volume is the diameter of the material (either 1.75mm or 2.85mm). Therefore, any variation in that diameter can cause the print to over or under extrude. In terms of raw materials - the filament diameter is one that requires a high level of confidence that you KNOW what you’re using.

MatterHackers Maintains Diameter Tolerance In Every Spool using Laser Gauges

Since we know diameter matters, we obsess over ensuring that PRO Series materials are on the mark so you can create perfectly printed parts. MatterHackers uses two and three-axis laser systems to measure and maintain the accuracy of the filament diameter at 40 hertz (40 times per second) - that way we know the filament diameter is consistent and within our 0.02mm diameter tolerance guarantee. Not only that, but the data for each production run is recorded and stored so we have traceability on all PRO Series materials to establish further confidence in each batch we produce.

Vibrant Color Consistency You Can Rely On

Rest assured knowing that MatterHackers controls and actively analyzes the compounding and coloration of each filament batch, ensuring that your projects are the same from spool to spool. Color continuity between batches is controlled and confirmed with a color-analyzing spectrometer running in line during filament production. Your PRO Series filament will always be the same color PRO Series filament.

TECHNICAL SPECIFICATIONS

- Printing Temperature: 220±10°C

- Print Bed Temperature: 60°C

- Spool Dimensions Spec Sheet

- True Diameter: 1.75mm or 2.85mm

- Dimensional Accuracy: ±0.02mm

- Density: 1.25 g/cm³

- Volume: 0.80 L

- Length: 332.6m (1.75mm) or 125.4m (2.85mm)

- Download the Technical Data Sheet

- Download the Safety Data Sheet

- RoHS & REACH Compliance

PRO Series Tough PLA 3D printing filament - strength and ease combined.

At MatterHackers, to bring you new and exciting products, we occasionally shift some of our quality stock to the Clearance section.

Reasons for Clearance Items:- New Product Versions: When manufacturers release updated versions of printers, CNC machines, filament, etc., the older versions typically go to Clearance.

- Overstock: Items we have in excess are moved to Clearance to free up warehouse space.

- Discontinuation: Discontinued product lines often end up in Clearance to expedite the sale of remaining stock.

- Packaging Changes: When packaging updates occur, we shift the older packaged items to Clearance.

- Poor Quality: Clearance items meet our rigorous quality standards and often brand new, unopened products.

- Limited Support: You'll receive our excellent customer service for Clearance items. Note, all Clearance purchases are Final Sale and not covered by the MatterHackers Return Policy.

Note, all Clearance purchases are Final Sale and not covered by the MatterHackers Return Policy.