UltiMaker UltiMaker Factor 4 Industrial 3D Printer

The UltiMaker Factor 4 is an industrial-grade 3D printer aimed at transforming manufacturing operations with its advanced technology and durable features. It promises precision, reliability, and efficiency, supporting the engineering process from concept to deployment. As a future-proof investment, it ensures accurate, reproducible, and predictable outcomes, ideal for both prototyping and small production batches or optimizing final product components.

Key Features of the UltiMaker Factor 4:

- Industrial-Grade Performance: Designed for the factory floor, offering high precision and reliability.

- Supports Full Engineering Process: From concept through development to deployment, facilitating a seamless transition.

- H-Bridge Gantry System: structural integrity that high accuracy and reproducabiltiy with easy servicability

- Closed Loop Motion Control: Finer control along all axes ensures finer detail in every print

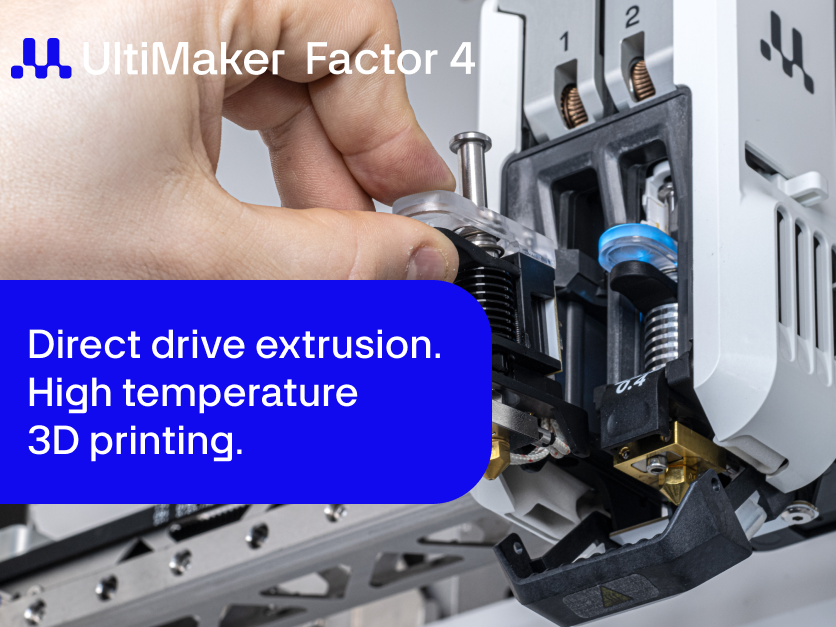

- Direct Drive Extrusion: a shorter filament path eliminates filament feed issues and lengthens uptime

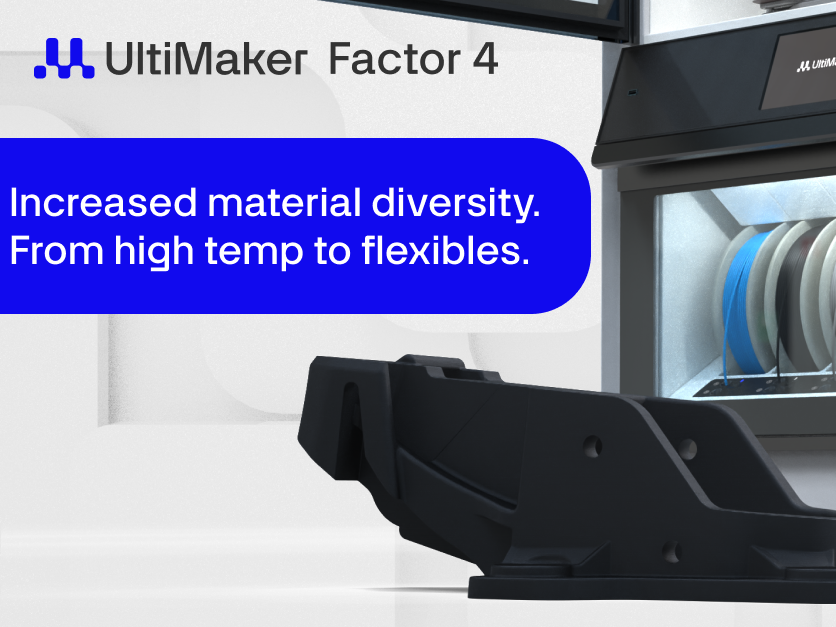

- Integrated Material Station: Automated pre-loading and spool switching, standard on day one

- Temperature Controlled Chamber: Ensure perfect layers with engineering grade materials in the 70C build volume

- New Core HT Compatible: Print advanced materials at up to 340C

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Upgrade to Carbon Fiber Printer for FREE

- 2x Spools of PET CF: High strength, high stiffness, and excellent heat resistance.

- 1x Print Core CC 0.60mm: Designed specifically to handle abrasive composite filaments with minimal degradation.

ULTIMAKER FACTOR 4

ACCURATE, REPEATABLE INDUSTRIAL 3D PRINTING

The UltiMaker Factor 4 3D Printer transforms manufacturing operations with its advanced technology and durable construction. It promises precision, reliability and efficiency, supporting the engineering process from concept to deployment.

Key Features of the UltiMaker Factor 4 3D Printer:

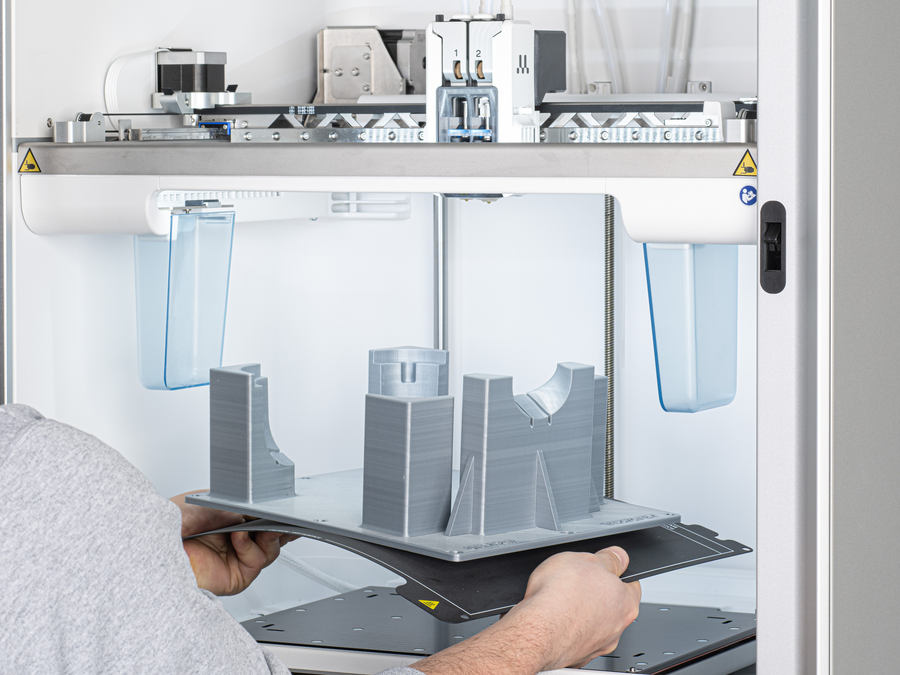

- Large Build Volume of 330 x 240 x 300mm

- 14+ UltiMaker materials and 250+ from the UltiMaker Marketplace

- 6-bay Material Handling System

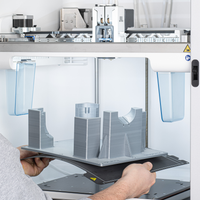

- PEI-coated flexible build plate and actively controlled build volume temperature

- HDR camera for print monitoring

- HEPA H13 filtration system for microparticulate control

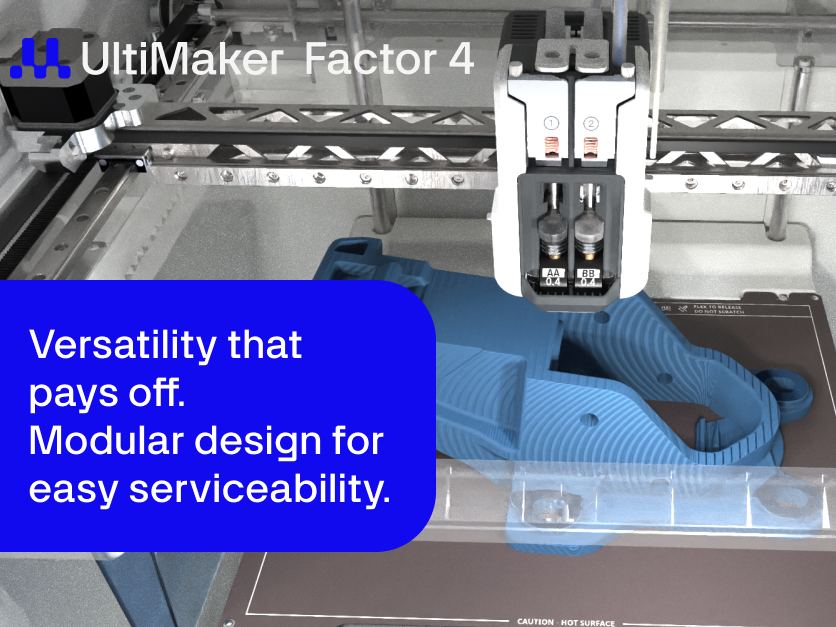

The UltiMaker Factor 4 features an H-Bridge Gantry system and a Closed Loop & Dual Direct Extrusion Print Head, ensuring high precision and reliability in every print. Coupled with its Insulated & Temperature-Controlled Build Volume up to 70°C, it guarantees optimal conditions for a wide range of materials.

- H-Bridge Gantry System: Ensures unmatched precision and reliability.

- Dual Direct Extrusion: Offers precise material control.

- Temperature-Controlled Volume: Ideal for diverse materials.

OPTIMIZED MATERIAL HANDLING

Equipped with a Low Humidity Material Handling system, the Factor 4 maintains material integrity from start to finish, enabling consistent and high-quality prints.

- Low Humidity System: Preserves material integrity.

- Consistent Quality: Ensures high-quality prints.

Built to withstand the rigors of the factory floor, the Factor 4 is a future-proof investment that bridges the gap between prototyping and small batch production. It supports engineers throughout the design process—from concept to deployment—enhancing manufacturing operations with an Open Material system, CURA slicer optimization, and Production Batch Reporting.

- Rugged for Factory Use: Withstands factory floor rigors.

- From Concept to Deployment: Supports the entire design process.

- Enhanced Manufacturing Operations: Offers Open Material system and CURA optimization.

ULTIMATE FLEXIBILITY & EFFICIENCY

Offering over 400 settings for optimization through the CURA slicer and benefiting from an Open Material system, the Factor 4 provides unparalleled flexibility and efficiency. Its industrial-grade performance ensures reliable, repeatable results, making it an invaluable tool for any manufacturing operation seeking to leverage the full potential of FDM 3D printing.

- Highly Customizable: Enables extensive optimization.

- Open Material System: Ensures flexibility and efficiency.

- Industrial-Grade Performance: Delivers reliable, repeatable results.

The UltiMaker Factor 4 Industrial 3D Printer, known for its reliability and high-quality material printing, can now be further enhanced with the optional UltiMaker Printer Station Mobile Cart. This combination not only elevates the printer's functionality but also its versatility in a factory setting, making it a powerhouse for any industrial 3D printing needs.

- Lockable casters allow effortless movement and secure placement of the Factor 4

- Optimizes organization, keeping everything within arm's reach.

PROTECT YOUR INVESTMENT WITH ULTIMAKER'S ENHANCED SERVICE PLAN (ESP)

When your business depends on quality 3D printing, it’s important to know you can rely on your 3D printers. That’s why MatterHackers offers Ultimaker’s Enhanced Service Plan (ESP) for customers in North America, to keep your 3D printers in perfect working order and help your business succeed. The UltiMaker Enhanced Service Plan extends and enhances the standard warranty coverage on UltiMaker hardware so you can avoid unbudgeted repair costs and still get the best possible service from MatterHackers’ Support Team. This peace of mind frees you to do what really matters: manage your business. Because when technology works, business works.

What are the Technical Specifications of the UltiMaker Factor 4 3D Printer?

| PRINTING PROPERTIES | |

|---|---|

| Technology | Fused Deposition Modeling (FDM) |

| Extrusion System |

Dual-extrusion - direct drive print head with unique auto-nozzle lifting system and swappable print cores

|

| Made In | Netherlands / USA |

| Build Volume (XYZ) |

330 x 240 x 300mm (13" x 9.4" x 11.8") |

| Filament Diameter | 2.85mm |

| Print Profiles Availability | 14+ UltiMaker materials 250+ UltiMaker Marketplace materials |

| HARDWARE PROPERTIES | |

| XYZ Resolution | 6.25, 7.8, 2.5 micron |

| Dimensional Accuracy | ±0.2mm ±0.2% feature nominal length |

| Homing sensor | Optical |

| Build Plate | PEI-coated flexible build plate |

| Build Plate Max Temp. | ≤ 120°C |

| Build Volume Temp. | Actively controlled, ≤ 70°C with nozzle plane temperature uniformity within: ± 3 °C for temperatures < 50 °C ± 5 °C for temperatures < 70 °C |

| Extrusion Flow | Closed loop flow compensation |

| Max. Extrusion | 280°C: Print Core AA, BB, DD 300°C: Print Core CC 340°C: Print Core HT |

| Closed Loops Fans | Air filtering fan, air recirculation fans, print cooling fans, print core cooling fan |

| Compatible Print Cores | |

|

Material Handling System Capacity |

6 bays with NFC recognition (max. 1 kg spool size) |

| Material Handling System Humidity Control | Average relative humidity <15% in all operational conditions |

| Microparticulate Filtration System | HEPA H13 |

| Emission Rate (UFP & VOC) | UltiMaker filaments below limits listed in UL-2904 |

| Monitoring | HDR (high dynamic range) 1920 x 1080 px HD camera |

| Display | 7-inch touchscreen (resolution 1024 x 600 px) |

| Connectivity | Wi-Fi 2.4 & 5 GHz: IEEE 802.11a/b/g/n/ac LAN: Gigabit Ethernet USB: 2.0 |

| System On Module | NXP i.MX8 Mini Quad (4 x 1.8 GHz), ARM Cortex-A53, 2 GB LPDDR 4 16 GB eMMC |

| Real time Controller | i.MX RT1064, Arm Cortex-M7 600 MHz, 1 MB SRAM |

| Power Requirement | 100 – 240 V AC, 50 – 60 Hz max., 6A |

| PHYSICAL DIMENSIONS | |

| Dimensions | 695mm x 605mm x 1287mm (27.5" x 24" x 51") |

| Weight | 120kg (265 lbs) |

| Shipping Dimensions | 760mm x 800mm x 1587mm (30" x 31.5" x 62.5") |

| Shipping Weight | 137kg (309 lbs) |

| SOFTWARE | |

|

Print job Preparation |

UltiMaker Cura 5.7.1 |

| Print Job Management | UltiMaker Digital Factory |

| Supported File Types | UltiMaker Cura: STL, OBJ, 3MF PrintableFormats: G, GCODE, UFP, STEP |

| Systems Requirements | MacOS, Windows OpenGL 2.1 4 GB RAM (8 GB recommended) |

| Print Process Reporting | Supported |

| Security | Active firewall PIN code settings protection |

| SAFETY & COMPLIANCE | |

| Warranty Period | 12 Months - (Enhanced Service Plans Upgrade Available) |

| Safety Features | Red stop button immediately stops motion and heat sources Open door sensor pauses motion and extrusion |

What is Included with the UltiMaker Factor 4 3D Printer?

| Printer | |

|---|---|

| UltiMaker Factor 4 3D Printer | |

| AA Print Core - 0.40mm |

x2

|

| Spool of TPLA Filament - Black | |

| Power Cord | |

| Tools | |

| Wire Cutter | |

| USB Stick | |

| Safety and Warranty Info | |

| Quick Start Guide |