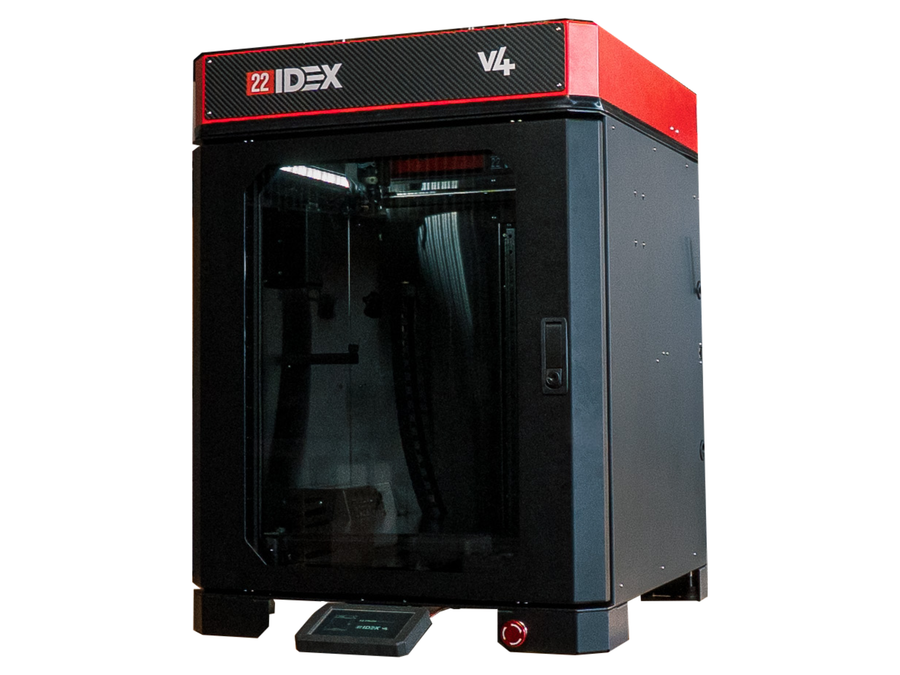

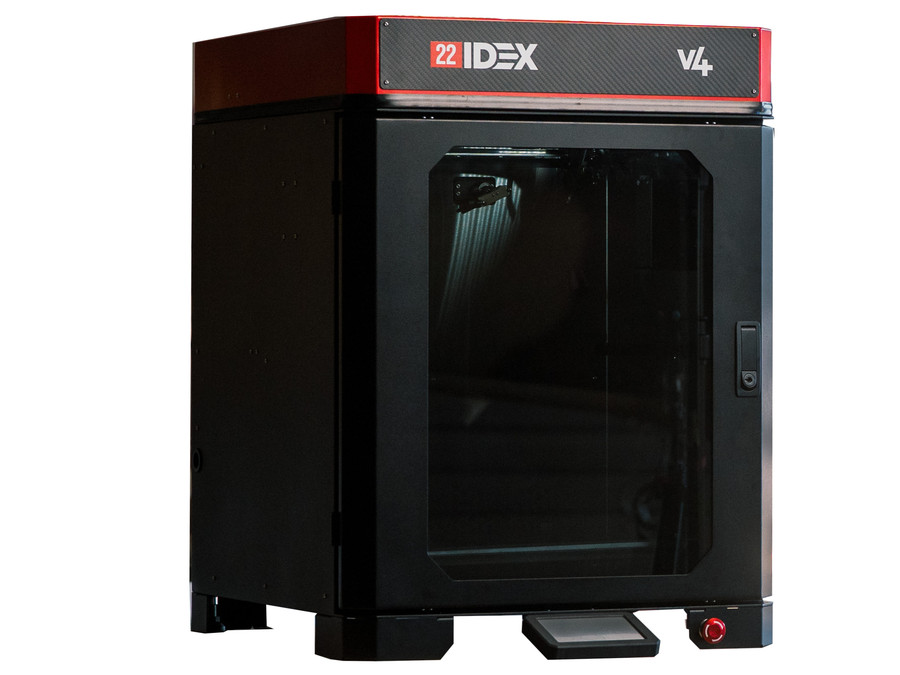

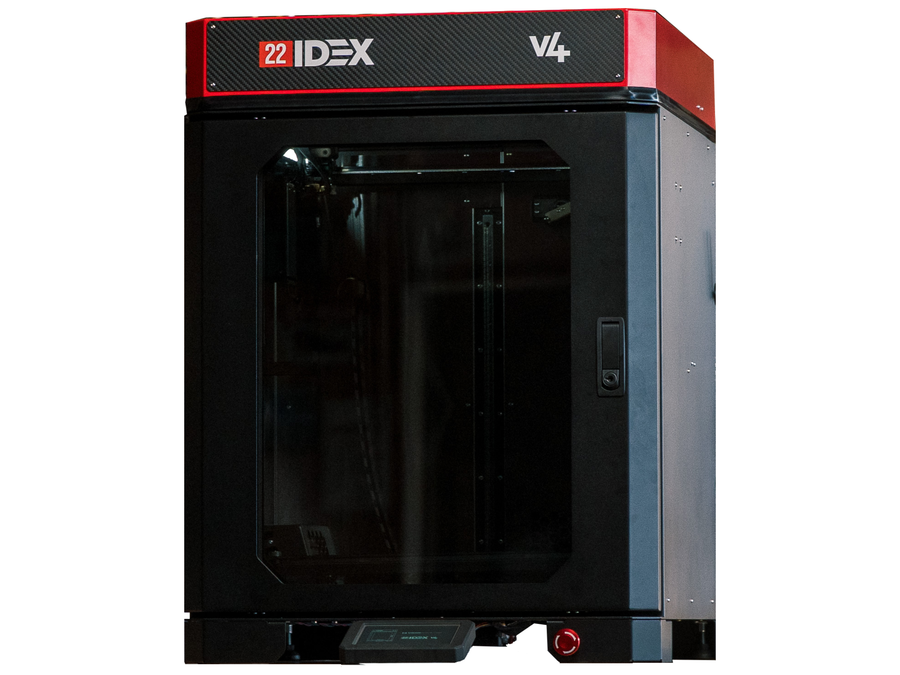

Vision Miner Vision Miner 22 IDEX V4 High Temperature 3D Printer

The Vision Miner 22 IDEX v4 is a pinnacle of high-temperature 3D printing technology, engineered for those who demand precision, versatility, and robust performance. With dual independent extruders capable of reaching 500°C and an actively-heated chamber, this printer is designed to handle the most challenging materials with ease. Its open material system and advanced automation features make it an ideal choice for professionals looking to push the boundaries of additive manufacturing without being confined to proprietary ecosystems. Built with insights from industry leaders and crafted with pride in the USA, the 22 IDEX v4 is ready to tackle any project, from aerospace to automotive, and beyond.

- Offers a spacious build area of 350 x 350 x 450 mm, accommodating substantial projects with ease.

- Dual independent extruders enable multi-material, soluble supports, duplication, and mirror modes, effectively functioning as two printers in one.

- Features a triple-motor, true self-leveling 200°C bed and a 100°C+ actively-heated chamber for reliable printing of ultra-performance polymers.

- Use a wide range of 1.75mm filaments, including high-temp and engineering-grade materials, offering unparalleled flexibility.

- Equipped with HEPA and carbon filtration systems to maintain clean air and ensure safety during operation.

- Includes a touchscreen interface for quick adjustments, along with lockable doors and lids for secure field deployment.

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Vision Miner 22 IDEX V4 High-Temperature 3D Printer

Revolutionizing High-Temperature Additive Manufacturing

The Vision Miner 22 IDEX V4 is a state-of-the-art, high-temperature, industrial-grade 3D printer, engineered to meet the demands of high-temperature additive manufacturing. This cutting-edge printer excels in producing durable and precise parts, making it ideal for industrial applications such as jigs, fixtures, vacuum molds, and press brake tooling. With its fully open material system, the 22 IDEX V4 offers unparalleled versatility, allowing you to work with a wide range of 1.75mm filaments, including advanced materials like PEEK, PEKK, and ULTEM™. Its integrated heated storage ensures your filaments remain dry and ready for ultra-long print times, even with hygroscopic polymers. Designed for those who demand the best, the 22 IDEX V4 delivers exceptional performance and adaptability.

Key Features of the 22 IDEX V4:

-

Dual independent extruders (capable of 500ºC) enable true IDEX printing for multi-material projects, duplication, and mirror modes, effectively doubling your productivity and expanding your creative possibilities.

-

An actively heated chamber (100ºC+) provides a stable environment for printing performance thermoplastics, ensuring strong mechanical properties and reducing warping and layer separation.

-

True self-leveling 200ºC build platform eliminates manual leveling with triple Z-Axis motors and advanced mesh leveling, ensuring consistent accuracy and reducing setup time.

-

Use a vast array of materials, including high-performance and engineering-grade polymers, for maximum versatility.

-

Integrated HEPA and carbon filtration maintains a clean 3D printing environment by reducing VOCs and particles, enhancing safety and air quality in your workspace.

-

Features over 100 micro-adjustments for improved usability, including an intuitive touchscreen interface and secure lockable doors, making the printer convenient and safe to use in any setting.

High-Temperature Capability

The Vision Miner 22 IDEX V4 is engineered to push the boundaries of high-temperature 3D printing, making it the perfect choice for professionals working with high-performance polymers. With dual independent extruders capable of reaching 500°C, this printer is designed to handle the most demanding materials like PEEK and ULTEM™, ensuring the production of robust, heat-resistant components essential for advanced industries.

-

Capable of 3D printing ultra-performance thermoplastics, allowing for multi-material printing, duplication, and mirror modes with both extruders reaching 500°C.

-

Ensures optimal adhesion and shape retention with a 200°C heated platform and triple-motor leveling system.

-

Maintains consistent internal temperatures over 100°C, enhancing interlayer bonding and mechanical properties for performance thermoplastics.

-

Enables the creation of durable, heat-resistant 3D printed parts for aerospace, automotive, and medical applications, meeting stringent industry standards.

Advanced Ventilation

Equipped with a sophisticated HEPA and Active Carbon Filtration system, the 22 IDEX V4 is designed to maintain superior air quality and optimize circulation, ensuring a pristine and stable environment for enhanced print performance and integrity.

- Effectively captures and eliminates particulates.

- Promotes stable temperature control - crucial for maintaining print quality and preventing defects.

- Honeycombed structures maximize airflow efficiency while creating a quieter workspace.

- Ensures a stable environment essential for high-temperature printing.

Secure Operations

The Vision Miner 22 IDEX V4 High Temperature 3D Printer features a robust lock system, enhancing safety and security, ensuring your 3D prints and environment remain protected, and providing peace of mind during operation.

- Prevents unauthorized access for safety.

- Protects sensitive, high-value projects.

- Durable and easy to use in industries.

- Quick, reliable access with key control.

Optimized Space

The Vision Miner 22 IDEX V4 3D Printer's internal filament housing maximizes functionality, keeping filament dry for long prints and preventing moisture uptake, even with hygroscopic polymers.

- Seamless design reduces clutter, keeps the workspace clean.

- Heated storage preserves filament quality and usability.

- Quick, easy filament changes for enhanced user experience.

- The design also supports larger external spools.

Control and Connectivity

The Vision Miner 22 IDEX V4 is equipped with advanced Duet 3 and 3HC Expansion Board controllers, supporting standard G-code and RepRap-based input files. Its modular, removable WiFi, integrated Ethernet, and USB terminal connection provide versatile connectivity options, ensuring seamless integration into any workflow.

- Sharp display for precise monitoring and control.

- Configure and control via standard internet browsers.

- Quick adjustments with a responsive touch interface.

- Real-time data aids informed decision-making.

WHICH VISION MINER 22 IDEX V4 BUNDLE IS RIGHT FOR ME?

| MAINTENANCE BUNDLE | PROFESSIONAL BUNDLE | PRODUCTION BUNDLE |

| IDEAL FOR... | ||

| Ensuring your 3D printer remains in peak condition and has the essential spare parts on hand. | Enhanced performance and versatility in 3D printing capabilities. | High-volume production environments where reliability and efficiency are paramount. |

| INCLUDES | ||

|

|

|

What are the Tech Specs of the 22 IDEX V4 3D Printer?

| Printing Technology | Fused Filament Fabrication, or Fused Deposition Modeling (FFF, FDM) |

| Build Volume |

|

| Build Platform Material |

|

| Motion System |

|

| Build Platform Leveling |

|

| Tool Heads |

|

| Layer Resolutions |

|

| Speeds |

|

| Filament Diameter |

Standard 1.75mm filament, Fully Open Material System |

| Nozzles |

Standard E3Dv6 style M6x1 threaded nozzles (Copperhead)

|

| Position Accuracy |

Hardware Maximums:

|

| Safety |

|

| Warranty | 1 year - premium & extended warranties available (contact sales@matterhackers.com) |

| Operating Temperatures |

|

| Fume Extraction/Filtration |

|

| Extruder Temperature | 500°C Maximum |

| Build Plate Temperature | 250°C Maxiumum |

| Chamber Temperature |

100°C+

|

| Mainboard Controllers | Duet 3, 3HC Expansion Board |

| Input File Type | Standard G-code, RepRap based |

| Compatible Slicers |

Any RepRap-Compatible slicer:

|

| Operator Interface |

|

| Internal Storage | 16GB (expandable, micro SD card) |

| Supported Computer OS | Windows, MacOS, Linux, Android, iOS - Control Panel uses standard internet browsers |

| Power Consumption |

For converting to 240V AC, heaters must be swapped for 240V versions, and power supplies can be switched to 240V AC. |

| Machine Dimensions |

Machine Dimensions: 535 x 568 x 739 mm 21.6" x 22.36" x 29.09" Recommended Footprint: 1000 x 600 x 1000 mm 40"x 24" x 40" Machine Weight: 200 lbs 90.7 kg |

| Shipping Weight & Dimensions |

Export-Compliant Crate 220lbs / 100kg 27"x26"x37" on Pallet 27"x26"x33" Corrugated Cardboard Box |

| Materials |

Any 1.75mm Filament: PEEK, PEKK, CFPEEK, AM200 PAEK, PEI, ULTEM™ 9085, ULTEM™ 1010, PEI Blends, PPSU, PA/CF, Nylon (PA66, PA6, PA12, etc), PC, PC Alloys, PA, ABS, ASA, Carbon Fiber-Filled, Metal-Filled, Glass-Filled, Nylon, PETG, ESD Materials, HIPS, TPU, PLA, PVA, and more. Carbon fiber and glass-filled variants of the above + Various soluble and break-away support materials, 100% Open Material System. |

| Materials/Filament Storage |

Integrated Heated Storage

Filament rests inside the heated chamber while printing, preventing moisture uptake, enabling ultra-long print times with hygroscopic polymers.

Filament can be fed from outside machines for larger spools.

|

For additional information, please download and view the 22 IDEX V4 Data and Technical Sheet

It is recommended to keep the original packaging, should you require repairs, refurbishment, etc.