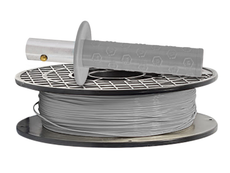

Bambu Lab Bambu Lab PET-CF Filament - 1.75mm

Bambu Lab PET-CF filament combines PET with carbon fiber to produce heat-resistant parts with low moisture absorption and strong layer adhesion. Its carbon-fiber reinforcement delivers high dimensional stability, making it suitable for load-bearing and high-temperature applications.

- Enable strength-critical applications with sustained structural integrity

- Parts retain dimensional stability under humidity

- Maintain performance under high temperatures

- Enclosed 3D printing is recommended

- Filament Diameter: 1.75mm ± 0.03mm

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Bambu Lab PET-CF Filament

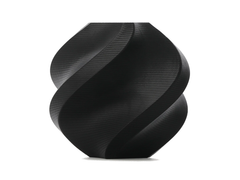

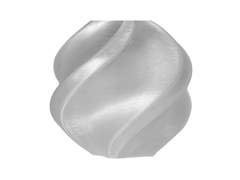

PRINT TOUGH PARTS WITH SMOOTH FINISHES

Bambu Lab PET-CF 3D Printer Filament blends tough PET with carbon fiber for outstanding strength, heat resistance, and dimensional stability. With low moisture absorption and great layer-to-layer, it’s perfect for load-bearing, high-temperature, and humid environments. Achieve precise, durable prints with a soft-glow finish—ideal for advanced engineering projects and reliable, functional parts.

Key Features of Bambu Lab PET-CF 3D Printer Filament:

- Exceptional strength and heat resistance for demanding applications

- Maintains quality and performance in humid environments

- Excellent layer-to-layer adhesion ensures precise, accurate prints

- Carbon fiber blend boosts durability for tough use cases

- Soft-glow finish for a professional look

- Comes with High Temperature Reusable Spool

- Requires Hardened Steel Nozzle sizes 0.4mm or larger

- NOT recommended for Bambu Lab AMS systems

WHY PRINT PET-CF?

Choose PET-CF for strong, dimensionally stable parts that perform reliably in humid or high-temperature environments. Its low moisture absorption and minimal warping make it ideal for functional components, mechanical assemblies, and automotive fixtures where lasting precision and durability truly matter.

- Excels in humid or high-temp conditions

- Reliable strength for functional parts

- Ideal for precise mechanical assemblies

CONSISTENT AGAINST HUMIDITY

Bambu Lab PET-CF resists moisture, maintaining its strength and stiffness even in humid environments. This low absorption makes it a smart choice for parts that need to perform reliably in demanding conditions, ensuring your prints stay strong and stable.

- Maintains strength in humid conditions

- Resists moisture for lasting durability

- Functional in wet or damp environments

DEPENDABLE DIMENSIONAL STABILITY

Stay true to your part's design with Bambu Lab PET-CF's strong layer-to-layer adhesion properties. This ensures your components maintain accurate shapes and consistent fit, making it ideal for projects where precision and reliable assembly are essential. Enjoy reliable results for both simple and complex designs.

- Maintains precise shapes and fit

- Retains original geometry for lasting accuracy

- Ideal for well-fitting multi-configurations

RELIABLE IN HOT CONDITIONS

With excellent thermal resistance, Bambu Lab PET-CF ensures your parts remain durable and precise even in hot environments. Choose this filament for applications where heat stability and long-lasting quality are essential, delivering reliable performance for advanced, temperature-demanding projects.

- Maintains properties in high heat

- Delivers reliable, stable performance

- Ideal for temperature-demanding projects

ACCESSORY COMPATIBILITY

| RECOMMENDED | NOT RECOMMENDED | |

| Build Plate | - Smooth PEI Plate - Textured PEI Plate - Cool Plate SuperTack |

— |

| Hotend | Hardened Steel Nozzle (0.4mm / 0.6mm / 0.8mm) |

Stainless Steel Nozzle (All Sizes) |

| Glue | Glue Stick | Bambu Liquid Glue |

FAQ

What is the difference between PET-CF and PETG-CF?

PET is polyethylene terephthalate and PETG is polyethylene terephthalate glycol. CF stands for the carbon fiber that is reinforced in both of these variations.

- This glycol-modified version of PET contains small amounts of glycol as a co-monomer. The addition of glycol reduces PET's crystallinity, making it more transparent, with the tradeoff being a reduction in strength and stiffness.

What are the differences in application between PETG-CF and PET-CF?

- PETG-CF is a versatile basic material that is suitable for printing functional parts. With its excellent toughness, it's ideal for applications such as bending, folding, and moving.

- PET-CF is an engineering-grade material that is suitable for more complex functional parts used in demanding environments. It contains a greater amount of carbon fiber and is significantly stronger and more temperature-resistant compared to PETG-CF.

What is PET-CF used for?

Due to its dimensional stability and lower water absorption rate, PET-CF is the ideal material for printing functional parts used in high-humidity environments. Also, its high-temperature resistance and low warping make it suitable for printing mechanical assembly parts, such as automotive accessories and fixtures.

PARAMETERS COMPARISON

| PET-CF | PAHT-CF | |

| Compotision | PET carbon fiber |

PA 12 & other long-chain PA (Nylon) carbon fiber |

| Hotend Compatibility |

Hardened Steel 0.4mm / 0.6mm / 0.8mm |

Hardened Steel 0.4mm / 0.6mm / 0.8mm |

| Build Plate Compatibility |

Smooth PEI Plate Textured PEI Plate High Temperature Plate Engineering Plate |

Smooth PEI Plate Textured PEI Plate High Temperature Plate Engineering Plate |

| Glue | Glue Stick | Glue Stick |

| AMS Compatibility | No | Yes |

| Print Speed | <100 mm/s | <100 mm/s |

| Toughness (Impact Strength - XY) |

36.0 kJ/m² | 57.5 kJ/m² |

| Strength (Impact Strength - XY) |

131 MPa | 125 MPa |

| Stiffness (Bending Strength - XY) |

5320 MPa | 4230 MPa |

| Layer Adhesion (Bending Modulus - Z) |

4.5 kJ/m² | 13.3 kJ/m² |

| Heat Resistant (HDT, 0.45 MPa) |

205°C | 194°C |

| Saturated Water Absorption Rate per % (25 °C,55% RH) |

0.37 | 0.88 |

Recommended Printing Settings

| Description | Value |

|---|---|

| Nozzle Temperature | 260 - 290 °C |

| Bed Temperature (with PVP Glue) | 80 - 100 °C |

| Drying Settings before Printing | 80 °C, 8 - 12 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Printing Speed | < 100 mm/s |

Physical Properties

| Property | Value |

|---|---|

| Density | 1.29 g/cm³ |

| Vicat Softening Temperature | 226 °C |

| Heat Deflection Temperature | 205 °C |

| Melting Temperature | 250 °C |

| Melt Index | 25.3 ± 2.5 g/10 min |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 74 ± 6 MPa |

| Breaking Elongation Rate | 4.5 ± 1.2 % |

| Bending Modulus | 5320 ± 270 MPa |

| Bending Strength | 131 ± 6 MPa |

| Impact Strength | 36.0 ± 2.7 kJ/m² |

PRINTING TIP(S)

- Store filament in a dry environment; PET-CF is sensitive to absorbing moisture.

- Actively drying it with a filament dryer at 80°C for 8 hrs before and after storage is recommended.

- An airtight storage container with desiccant is recommended before, during, and after printing.

- Printing in an open 3D printer is possible, but an enclosure is recommended.

- An abrasive-resistant nozzle (hardened steel, tungsten carbide, ruby-tipped, etc.) is required.

- Using a non-abrasive-resistant nozzle is possible, but will very quickly degrade the nozzle, leading to frequent replacements and print quality issues.

- For streamlined filament extrusion, composite-reinforced filaments must print out of a nozzle that's, at minimum, 0.4mm in diameter.

WHAT'S INCLUDED?

1 × Filament with Spool & Desiccant |

1 × Package |