UltiMaker UltiMaker S7 3D Printer

The Ultimaker S7 3D Printer and S7 Pro Bundle deliver reliable, professional-grade 3D printing with a host of advanced features that ensure accuracy and ease of use. Designed for "right the first time" results, these printers come equipped with an integrated Air Manager, inductive sensor bed leveling, a PEI-coated flexible build plate, a print head anti-flood sensor, bed tilt compensation, and 5 GHz Wi-Fi connectivity. The flexible build plate allows for simple and quick removal of prints, and the system is compatible with swappable print cores for handling a variety of materials and jobs.

- Integrated Air Manager: Ensures a safe and controlled printing environment.

- Inductive Sensor Bed Leveling: Provides precise bed leveling for accurate prints.

- High-Definition On-Board Camera: Monitors print progress in real-time.

- Material Station (Pro Bundle): Enhances material management and workflow efficiency.

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

ULTIMAKER S7

"RIGHT THE FIRST TIME" PROFESSIONAL 3D PRINTING

The Ultimaker S7 3D Printer delivers high-quality parts and models with ease and reliability, ensuring a professional 3D printing experience from the first layer to the last.

Key Features of the Ultimaker S7 3D Printer:

- Integrated Air Manager: Ensures a safe and controlled printing environment.

- Inductive Sensor Bed Leveling: Provides precise bed leveling for accurate prints.

- PEI Coated Flexible Build Plate: Allows for simple and quick removal of prints.

- High-Definition On-Board Camera: Monitors print progress in real-time.

- Print Head Anti-Flood Sensor: Prevents print head flooding for consistent quality.

- Bed Tilt Compensation: Maintains optimal bed alignment for flawless prints.

- 5 GHz Wi-Fi Compatibility: Offers fast and reliable wireless connectivity.

The Ultimaker S7 3D Printer delivers ultimate temperature control, ensuring that external conditions do not affect the success of your print results. This feature is crucial for achieving professional-grade 3D printing quality.

Key Temperature Control Features:

- Integrated Air Manager: Regulates chamber temperature and filters ultrafine particles (UFP).

- Single Door Design: Minimizes cracks for external airflow, preventing part warping.

- Even Heat Distribution: The build plate is designed to evenly distribute heat, keeping your entire first layer perfect.

EFFORTLESS EASE OF USE

Succeeding with a wide variety of materials is easy and effortless with the Ultimaker S7 3D Printer. This printer is designed to simplify the 3D printing process while ensuring high-quality results.

Ease of Use Features:

- Flexible Build Plate: Allows for simple and quick removal of prints.

- PEI-Coated Plate: Enhances material compatibility and reduces the need for additional adhesives.

- Swappable Print Cores: Easily accommodate any application need with interchangeable print cores.

STREAMLINED SETUP OUT OF THE BOX

Installing the Ultimaker S7 3D Printer out of the box takes just 30 minutes, getting you ready to print in no time. The setup process has been thoughtfully improved for ease and efficiency.

Setup and Calibration Features:

- Patent-Pending Technology: Automatically aligns the build plate every time.

- Hardware and Firmware-Assisted Automation: Simplifies the calibration process.

- Fully-Assembled: The Ultimaker S7 arrives fully assembled, ready to use.

ACCESSIBLE FIRST-TIME-RIGHT SUCCESS

A good first layer adhesion is fundamental to successful 3D printing, and the Ultimaker S7 3D Printer makes it achievable for a wider audience using a combination of the latest advanced technologies.

First Layer Success Features:

- Inductive Sensor: Probes the bed with high dimensional accuracy.

- Automatic Tilt Compensation: Eliminates the need for manual thumbscrew bed calibration.

- Onboard Camera: Mounted high for a great view of the first layers.

OPTIMAL PRODUCTION WORKFLOW

The UltiMaker S7 3D Printer utilizes the latest technology and designs to optimize your production workflow, providing an enhanced professional 3D printing experience.

Workflow Optimization Features:

- 1080p Camera: Provides high-definition monitoring of prints.

- 5 GHz Wi-Fi Compatibility: Offers improved network stability.

- Integrated Carrying Handles: Designed for safe portability.

- Anti-Flood Sensor: Increases protection against potential costly maintenance.

PUTTING THE "PRO" IN PRODUCTIVE

The Ultimaker S7 Pro maximizes productivity by combining with the Material Station—the accessory designed to simplify and automate the material handling process.

Material Handling Features:

- Holds Up to 6 Spools of Material: Ensures you have plenty of material for extensive print jobs.

- Automatic Material Loading: Streamlines the process by automatically loading materials into the printer.

- Reduces Material Run-Out: Minimizes interruptions by reducing instances of running out of material mid-print.

- Humidity Control: Maintains optimal filament conditions within the Station's chamber.

ULTIMATE ULTIMAKER CONNECTIVITY

Whether it's hardware, software, or materials, the Ultimaker S7 3D Printer is integrated across the entire extensive Ultimaker Platform, ensuring a seamless experience with the existing ecosystem.

Connectivity and Integration Features:

- Securely Manage & Monitor Prints: Utilize the Ultimaker Digital Factory for secure print management and monitoring.

- Access E-Learning Courses: Enhance your skills with courses available on Ultimaker Academy.

- Extensive Material and Plugin Options: Choose from hundreds of materials and plugins in the Ultimaker Marketplace.

Level Up with UltiMakerCare

Hot Swap Service

UltiMaker Care offers an invaluable Hot Swap Service, ensuring minimal disruption to your 3D printing workflow. If your printer encounters an issue covered by the plan, you’ll receive a replacement device immediately, keeping your projects on track.

- Minimized Downtime: Receive a replacement printer right away, ensuring your operations are never at a standstill.

- Peace of Mind: Focus on your work without worrying about unexpected printer issues.

- Reliable Support: Trust in a service that prioritizes your productivity and efficiency.

Direct Access to MakerBot Support Engineers

MakerCare provides direct access to MakerBot Support Engineers, offering expert assistance whenever you need it. Whether through phone, email, or live chat, our team of 3D printing experts is ready to help you resolve any issues or answer any questions.

- Multiple Contact Options: Reach out via phone, email, or live chat for convenient support.

- Expert Guidance: Get direct advice from 3D printing professionals to keep your printer functioning optimally.

- Timely Assistance: Contact us Monday through Friday, 9 am - 6 pm ET, or email us for a response within 6 business hours.

WHICH S-SERIES ULTIMAKER IS RIGHT FOR ME?

Determine which S-Series Ultimaker 3D printer is right for you using the table below, or request a quote for assistance from one of our expert Sales Representatives!

| UltiMaker S8 Starting at $8,999 |

UltiMaker S7 Starting at $7,999 |

UltiMaker S6 Starting at $6,950 |

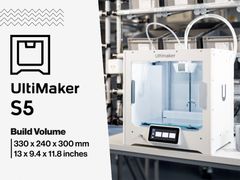

UltiMaker S5 Starting at $6,950 |

UltiMaker S3 Starting at $4,450 |

| HIGHLIGHTS ✓ High Speed ✓ Perfect probing ✓ Large volume ✓ Fully enclosed ✓ Widest material compatibility ✓ Professional results |

✓ Perfect probing ✓ Large volume ✓ Fully enclosed ✓ Wide material compatibility ✓ Professional results |

✓ High Speed ✓ Perfect probing ✓ Large volume ✓ Modular ✓ Widest material compatibility ✓ Professional results |

✓ Large volume ✓ Modular ✓ Wide material compatibility ✓ Professional results |

✓ Entry-level ✓ Compact ✓ Professional results |

| ENCLOSED Fully |

Fully |

Partially |

Partially |

Partially |

| AIR MANAGER Integrated |

Integrated |

Optional |

Optional |

— |

| ULTIMAKER CHEETAH Yes |

No |

Yes |

No |

No |

| MAX NOZZLE TEMP Up to 340°C |

Up to 280°C |

Up to 340°C |

Up to 280°C |

Up to 280°C |

| COMPATIBILITY 301+ materials |

280+ materials |

301+ materials |

280+ materials |

190+ materials |

| EXTRUSION FLOW Up to 35mm3/s |

Up to 24mm3/s |

Up to 35mm3/s |

Up to 24mm3/s |

Up to 24mm3/s |

| BED LEVELING Automated |

Automated |

Automated |

Manual |

Manual |

| FLOOD DETECTION Yes |

Yes |

Yes |

No |

No |

| BUILD PLATE Flexible PEI |

Flexible PEI |

Glass OR Flexible PEI |

Glass |

Glass |

| # OF SPOOLS Up to 6 (with Material Station) |

Up to 6 (with Material Station) |

Up to 6 (with Material Station) |

Up to 6 (with Material Station) |

Up to 2 |

| BUILD VOLUME (mm) L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 230 (9") W: 190 (7.4") H: 200 (7.9") |

What's Included with the UltiMaker S7 3D Printer?

| 1 | x | UltiMaker S7 3D Printer •1 x 0.4 AA Print Core (installed) •1 x 0.4 BB Print Core (installed) |

| 1 | x | Additional 0.4 AA Print Core |

| 1 | x | PEI Coated Flexible Build Plate |

| 1 | x | Spool Holder with Material Guide |

| 1 | x | Power Adapter & Cable |

| 1 | x | Ethernet Cable |

| 1 | x | USB Stick |

| 3 | x | Nozzle Cover |

| 1 | x | Tough PLA Filament (750g) |

| 1 | x | PVA Soluble Support Filament (750g) |

| 1 | x | Oil & Grease for Maintenance |

| 1 | x | Hex Screwdriver (2 mm) |

| 1 | x | XY Calibration Sheet |

| 1 | x | Quick Start Guide |

| 1 | x | Safety & Warranty Booklet |

Also 1 x Material Station if purchasing the UltiMaker S7 Pro Version)

What are the Technical Specifications of the UltiMaker S7 3D Printer?

| PRINTER/PRINTING PROPERTIES | |

|---|---|

| Technology | Fused Filament Fabrication (FFF) |

| Assembly | Fully-Assembled |

| Made in | Netherlands / USA |

| Build Volume (XYZ) |

330 x 240 x 300mm (13" x 9.4" x 11.8") |

| Layer Resolution | 0.25mm Nozzle: 150 - 60 micron 0.4mm Nozzle: 200 - 20 micron 0.6mm Nozzle: 300 - 20 micron 0.8mm Nozzle: 150 - 20 micron |

| XYZ Resolution | 6.9, 6.9, 2.5 micron |

| Build Speed | < 24mm3/s |

| Print Head | Dual Extrusion |

| Tool Head System | Swappable Print Cores |

| Includes Auto-Nozzle Lifting System | Yes |

| Includes Material Flow Sensor | Yes |

| Build Plate | Double-sided PEI Coated Flexible Build Plate (20 - 140°C) |

| Air Manager | EPA filter - Independently tested according to UL2904 (Standard Method for Testing and Assessing Particle and Chemical Emissions from 3D Printers) with UltiMaker materials and corresponding Cura print profiles |

| Nozzle Diameter | 0.4mm (included) 0.25mm, 0.6mm, 0.8mm (sold separately) |

| Operating Sound | < 50 dBA |

| Connectivity | WiFi / Ethernet / USB / cloud |

| LCD Screen | Interactive Touchscreen |

| On-board Camera | Built-in |

| Camera Resolution | High Definition |

| Material Station's Feeder Type (included w/ Pro Bundle) |

Dual-geared, Abrasion-resistant |

| Material Station's Spool Bays (included w/ Pro Bundle) |

6 with NFC Recognition |

| PHYSICAL DIMENSIONS | |

| Dimensions (w/ spool holder) (W × D × H) |

Printer Only 495mm x 585mm x 780mm (19.5" × 23" × 30.7") Pro Bundle 495mm x 500mm x 1190mm (19.5" x 19.7" x 46.9") |

| Net Weight | Printer Only 29.1kg (64.2 lbs) Pro Bundle 46.7kg (103 lbs) |

| SOFTWARE | |

| Free Supplied Software | UltiMaker Personal (plus UltiMaker Cura for individuals) Essentials (for organizations - includes UltiMaker Cura Enterprise) |

| Supported File Types | STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG |

| Output File Types | G, GCODE, GCODE.gz, UFP |

| OS compatibility | MacOS, Windows, and Linux |

| WARRANTY | |

| Warranty Period | 12 Months - (Enhanced Service Plans Upgrade Available) |

FAQ

Is the UltiMaker Metal Expansion Kit compatible with the UltiMaker S7?

The current Metal Expansion Kit for the UltiMaker S5 is NOT compatible with the UltiMaker S7. A specific solution for the S7 will be coming soon.

What materials are compatible with the UltiMaker S7?

The UltiMaker S7 can handle nearly every material available for desktop 3D printing, including but not limited to:

- PLA and Tough PLA

- ABS

- PETG and CPE

- ASA

- Nylon, NylonX and NylonG

- Ultrafuse 316L and 17-4 PH (coming soon)

- TPU and TPE

- PVA and Soluble Supports

- Polycarbonate

- Polypropylene

- Metal (coming soon)

Will third-party materials from the UltiMaker Marketplace be supported on the UltiMaker S7?

Yes, the UltiMaker S7 supports third-party materials available in the UltiMaker Marketplace.

Can composite materials be used on the UltiMaker S7?

Yes—with the use of a CC Print Core (sold separately).

Which print cores can be used on the UltiMaker S7?

The UltiMaker S7 works with the swappable print cores compatible with S-line printers: AA0.25, AA0.4, AA0.8, BB0.4, BB0.8, CC0.4, CC0.6.

What software is compatible with the UltiMaker S7?

The UltiMaker S7 is fully compatible with the software suite available with the UltiMaker Platform, including UltiMaker Cura and Digital Factory.

Are there differences between the print profiles for the UltiMaker S7 and the UltiMaker S5?

No—print jobs prepared for the UltiMaker S5 (.gcode and .ufp) are fully compatible with the UltiMaker S7.

Should I use glue on the flexible build plate?

It is not recommended unless specifically advised by the material manufacturer. Most materials can (and should) be printed directly on the flexible build plate, without additional adhesive. UltiMaker materials are printed on a clean build plate, without glue. Some third-party materials may require a specialized glue for optimal adhesion.

Is the PEI coating on both sides of the UltiMaker S7's flexible build plate?

Yes, the PEI coating is on both sides of the UltiMaker S7's flexible build plate.

Can the UltiMaker S7 flexible build plate also be used on the UltiMaker S5?

No, the flexible build plate is not compatible with the UltiMaker S5. There are more differences between the Z stages of the UltiMaker S5 and UltiMaker S7.

Boost Your 3D Printing with the UltiMaker Speed Pack

UltiMaker has turbocharged its S series 3D printers, enabling them to print up to twice as fast. Add on the UltiMaker Speed Pack to print even faster!