UltiMaker UltiMaker S5 3D Printer

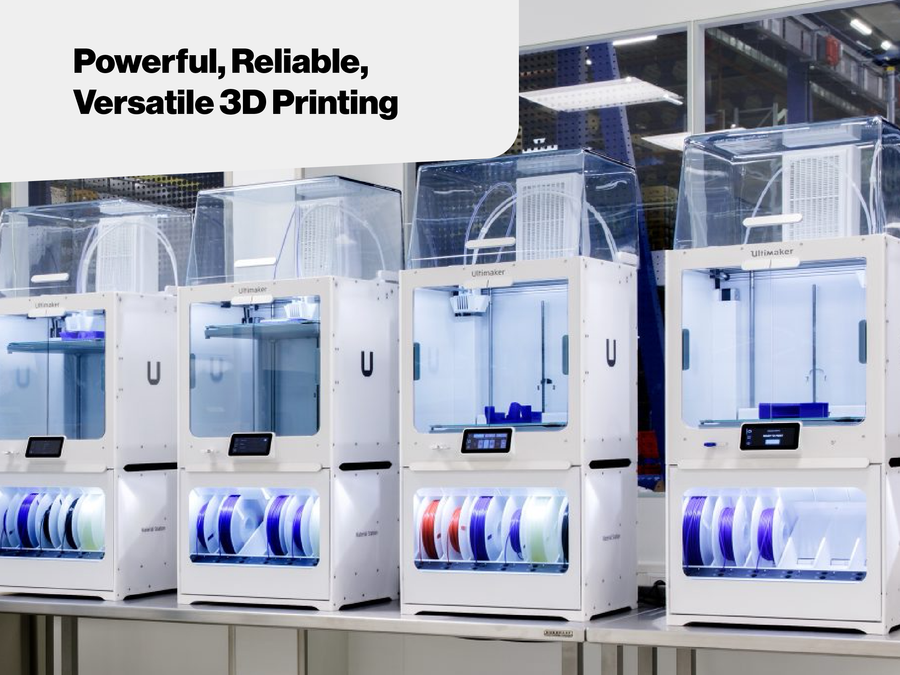

The UltiMaker S5 3D printer is a powerful, large-format, dual extrusion 3D printer that is the most reliable and easy-to-use 3D printer for professional, industrial, and educational use.

Top UltiMaker S5 3D Printer Features:

• Large-format - 330 x 240 x 300 mm

• Dual Extrusion - print with multiple materials at once

• Swappable Print Cores - print with advanced materials

• Includes free Essentials software - upgrades available

• Includes one year of free warranty - upgrades available

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Looking for the UltiMaker S5 Pro? Click here!

The UltiMaker S5

A Powerful, Large-Format, Dual Extrusion 3D Printer

The UltiMaker S5 3D Printer is a reliable and easy-to-use machine that's great for professionals, educators, and any industrial or manufacturing applications.

Here are the key features of the UltiMaker S5 3D printer:

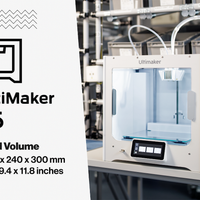

- Large Build Volume

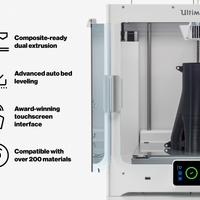

- Dual Extrusion Capabilities

- Swappable Print Cores

- Print with Any Material

- Automatic Bed Leveling

- Onboard Camera

- Free UltiMaker Essentials Software

Boost Your 3D Printing with the UltiMaker Speed Pack

UltiMaker has turbocharged its S series 3D printers, enabling them to print up to twice as fast. Add on the UltiMaker Speed Pack to print even faster!

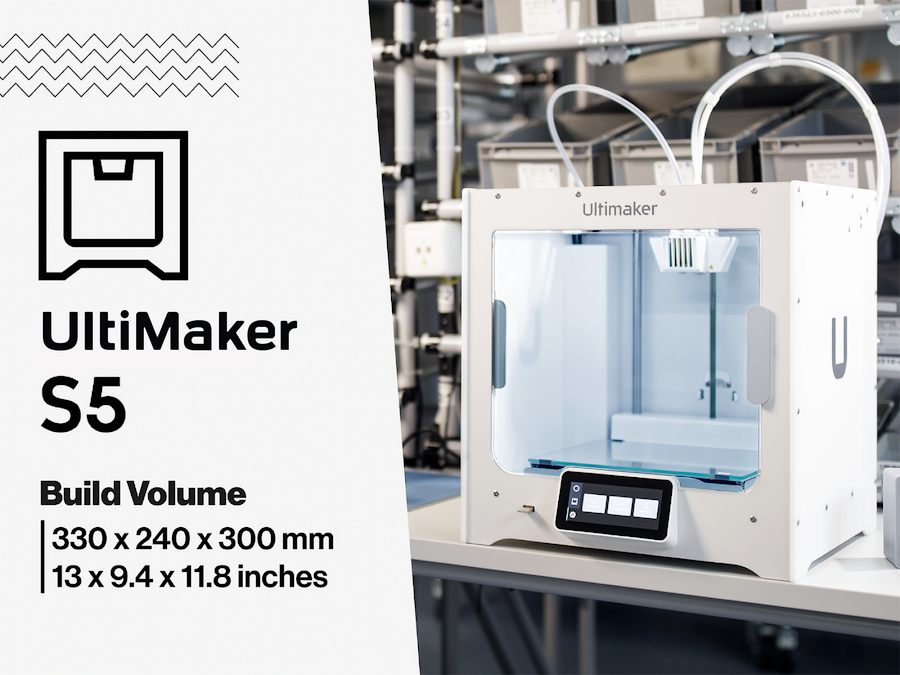

Print Large, Functional Parts

The UltiMaker S5 3D printer has one of the largest build volumes available, allowing you to create large, end-use parts, prototypes, and custom jigs and fixtures.

- Build Volume: 330 x 240 x 300 mm

- Prototype & create large end-use parts in-house

- Print more parts at once

- Beneficial for a wide variety of industries

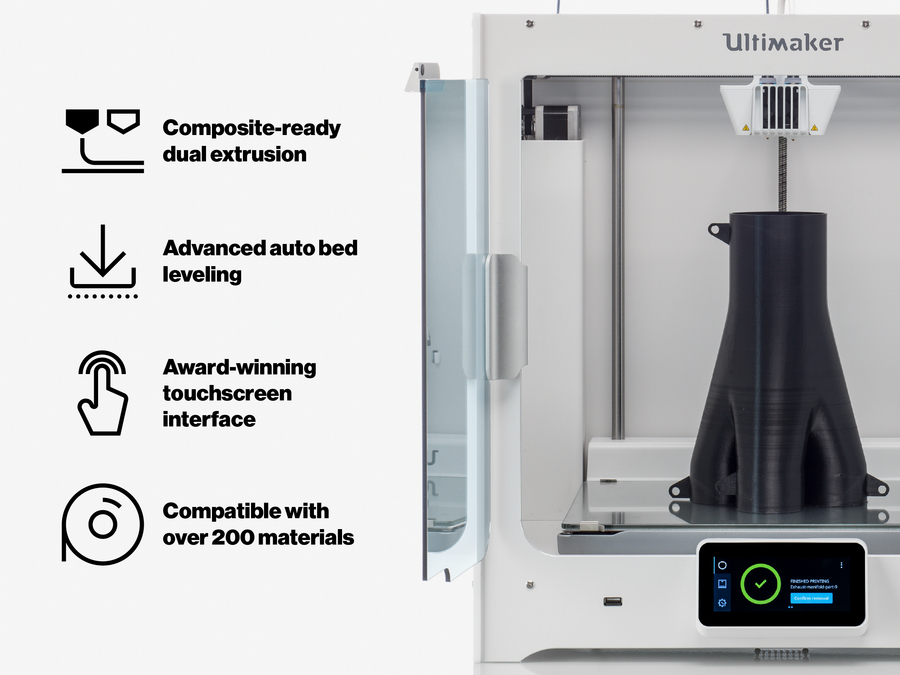

Powerful, Dual Extrusion 3D Printing

The UltiMaker S5 3D printer has a top-tier dual extrusion system that produces clean, geometrically complex parts.

- Use multiple materials at once

- 3D print complex parts with soluble support structures

- Articulating nozzle-lifting system for cleaner prints

Successfully 3D Print with Any Material

The UltiMaker S5 3D printer has swappable print cores, making it incredibly easy to print between a wide range of materials, including advanced materials like NylonX and even stainless steel metal.

- Use a variety of Print Cores designed to help you succeed with any material.

- Pivot quickly to new projects with the simple print core system.

- Over 200 tested materials are available, including metal.

Flawless Prints, Time and Time Again

The UltiMaker S5 3D printer's automatic leveling system makes it easy to get started printing quickly so you can keep productivity up.

- Automatic bed leveling ensures great prints every time.

- Enhanced filament feed system and dual filament flow sensors.

- Filament flow sensors - never lose a print.

Award-Winning Interface and Remote Print Monitoring

The UltiMaker S5 3D printer has swappable print cores, making it incredibly easy to print between a wide range of materials, including advanced materials like NylonX and even stainless steel metal.

- 4.7 inch touchscreen for smooth interface control.

- Monitor your print job’s progress remotely via onboard camera.

- Print remotely over Wi-Fi directly to your Ultimaker S5

What Materials Can I Print with the UltiMaker S5 3D Printer?

The UltiMaker S5 can handle nearly every material available for desktop 3D printing, including advanced materials and composites like carbon fiber-infused NylonX and Ultrafuse Stainless Steel Metal filaments. Here is a list of 3D printing materials compatible with the UltiMaker S5:

- PLA and Tough PLA

- ABS

- PETG and CPE

- ASA

- Nylon, NylonX and NylonG

- Ultrafuse 316L and 17-4 PH

- TPU and TPE

- PVA and Soluble Supports

- Polycarbonate

- Polypropylene

- View all UltiMaker S5 Compatible materials here.

UltiMaker 3D printers are being used successfully in many industries, including aerospace, automotive, manufacturing, and education.

Streamline your Workflow with UltiMaker Essentials

UltiMaker Essentials is free with the UltiMaker S5, giving you the power to print remotely via cloud data with increased security and better print queue management.

- Reprint from queue history easily to keep production moving.

- Duplicate and reorder print jobs without reslicing.

- Upgrade to Ultimaker's Enterprise software to increase team productivity on a larger scale.

WHICH S-SERIES ULTIMAKER IS RIGHT FOR ME?

Determine which S-Series Ultimaker 3D printer is right for you using the table below, or request a quote for assistance from one of our expert Sales Representatives!

| UltiMaker S8 Starting at $8,999 |

UltiMaker S7 Starting at $7,999 |

UltiMaker S6 Starting at $6,950 |

UltiMaker S5 Starting at $6,950 |

UltiMaker S3 Starting at $4,450 |

| HIGHLIGHTS ✓ High Speed ✓ Perfect probing ✓ Large volume ✓ Fully enclosed ✓ Widest material compatibility ✓ Professional results |

✓ Perfect probing ✓ Large volume ✓ Fully enclosed ✓ Wide material compatibility ✓ Professional results |

✓ High Speed ✓ Perfect probing ✓ Large volume ✓ Modular ✓ Widest material compatibility ✓ Professional results |

✓ Large volume ✓ Modular ✓ Wide material compatibility ✓ Professional results |

✓ Entry-level ✓ Compact ✓ Professional results |

| ENCLOSED Fully |

Fully |

Partially |

Partially |

Partially |

| AIR MANAGER Integrated |

Integrated |

Optional |

Optional |

— |

| ULTIMAKER CHEETAH Yes |

No |

Yes |

No |

No |

| MAX NOZZLE TEMP Up to 340°C |

Up to 280°C |

Up to 340°C |

Up to 280°C |

Up to 280°C |

| COMPATIBILITY 301+ materials |

280+ materials |

301+ materials |

280+ materials |

190+ materials |

| EXTRUSION FLOW Up to 35mm3/s |

Up to 24mm3/s |

Up to 35mm3/s |

Up to 24mm3/s |

Up to 24mm3/s |

| BED LEVELING Automated |

Automated |

Automated |

Manual |

Manual |

| FLOOD DETECTION Yes |

Yes |

Yes |

No |

No |

| BUILD PLATE Flexible PEI |

Flexible PEI |

Glass OR Flexible PEI |

Glass |

Glass |

| # OF SPOOLS Up to 6 (with Material Station) |

Up to 6 (with Material Station) |

Up to 6 (with Material Station) |

Up to 6 (with Material Station) |

Up to 2 |

| BUILD VOLUME (mm) L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 230 (9") W: 190 (7.4") H: 200 (7.9") |

What Comes with the UltiMaker S5 3D Printer?

ACCESSORIES

- Glass Build Plate

- Spool Holder with Material Guide

- Power Cable

- Ethernet Cable

- USB Stick

- Print core AA 0.4 (an additional AA Core is already installed)

- Print core BB 0.4 (already installed)

- Nozzle cover (3x)

CONSUMABLES

- Tough PLA Filament (750 g)

- PVA Soluble Support Filament (750 g)

- Glue Stick for Bed Adhesion

- Oil & Grease for Maintenance

TOOLS

- Hex Screwdriver (2 mm)

- XY Calibration Sheet

- Calibration Card

Level Up with UltiMakerCare

Hot Swap Service

UltiMaker Care offers an invaluable Hot Swap Service, ensuring minimal disruption to your 3D printing workflow. If your printer encounters an issue covered by the plan, you’ll receive a replacement device immediately, keeping your projects on track.

- Minimized Downtime: Receive a replacement printer right away, ensuring your operations are never at a standstill.

- Peace of Mind: Focus on your work without worrying about unexpected printer issues.

- Reliable Support: Trust in a service that prioritizes your productivity and efficiency.

Direct Access to MakerBot Support Engineers

MakerCare provides direct access to MakerBot Support Engineers, offering expert assistance whenever you need it. Whether through phone, email, or live chat, our team of 3D printing experts is ready to help you resolve any issues or answer any questions.

- Multiple Contact Options: Reach out via phone, email, or live chat for convenient support.

- Expert Guidance: Get direct advice from 3D printing professionals to keep your printer functioning optimally.

- Timely Assistance: Contact us Monday through Friday, 9 am - 6 pm ET, or email us for a response within 6 business hours.

UltiMaker S5 3D Printer Technical Specifications

What are the Dimensions for the S5?

- Build Volume: 330 x 240 x 300 mm (13 x 9.5 x 11.8 inches)

- Assembled Dimensions (with spool holder installed): 495 x 585 x 780 mm (19.5 x 23 x 30.7 inches)

- Compatible filament diameter: 2.85mm

- Weight: 20.6 kg (45.4 lbs)

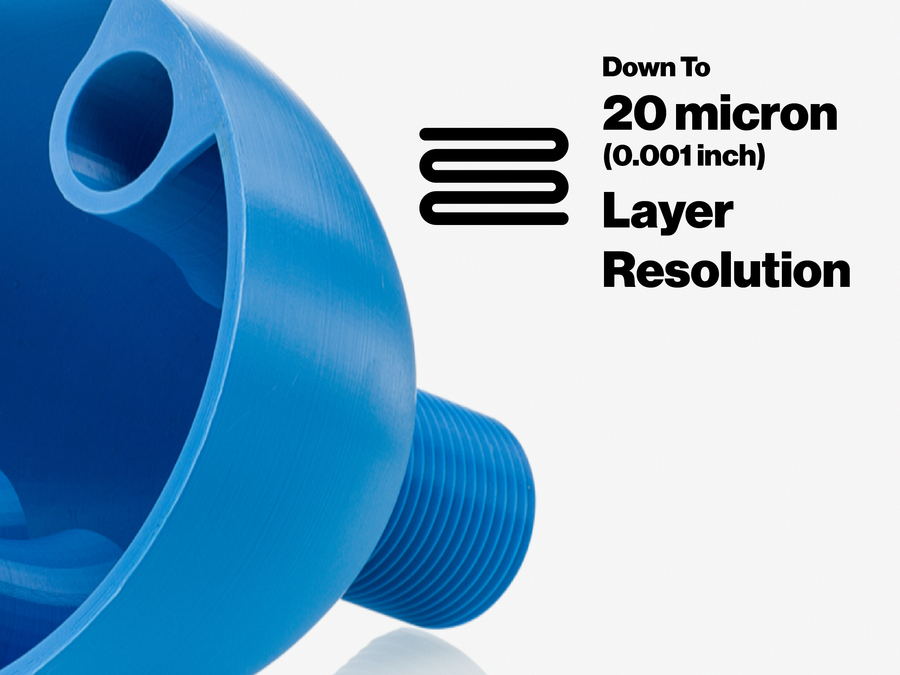

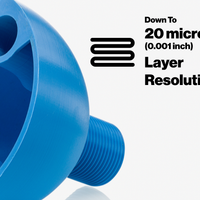

What are the UltiMaker S5's printer properties?

- Print Technology: FFF (Fused filament fabrication)

- Maximum Power Output: 500 W

- Layer Resolution: 200 - 20 micron with 0.4mm nozzle (stock), 150 - 60 micron with 0.25 mm nozzle, 300 - 20 micron with 0.6 mm nozzle, and 600 - 20 micron with 0.8mm nozzle. Additional print cores are available here.

- XYZ Resolution: 6.9, 6.9, 2.5 micron

- Build Speed: < 24 mm³/s

- Nozzle Temperature: 180 - 280 °C

- Nozzle Heat Up Time: < 2 minutes

- Operating Sound: < 50 dBA

- Build Plate: Heated glass bed - 20 - 140 °C

- Build Plate Leveling: automatic advanced leveling

- Feeder Type: Dual-geared feeder designed for advanced composite materials

- Touchscreen Display: 4.7-inch (11.9 cm) color

- Print Head: Dual extrusion print head with an articulating nozzle-lifting system

- Print Core and Nozzles Replacement: Swappable Print Cores

- Nozzles Diameters: arrives with 0.4 mm, but 0.25 mm, 0.6 mm, and 0.8 mm are available here.

What is the Software for the UltiMaker S5?

- UltiMaker Cura: print preparation software (free)

- UltiMaker Essentials: printer management software (free and available to upgrade for enterprise solutions)

- Supported OS: MacOS, Windows, and Linux

- Supported File Types: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

- Printable Formats: G, GCODE, GCODE.gz, UFP

- File Transfer: Wi-Fi, Ethernet, USB