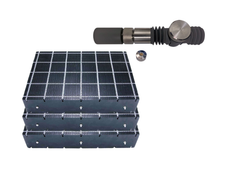

WAZER WAZER Cut Bed (3 Pack)

WAZER Cut Bed (3 Pack) contains 3 replacement cut beds when the time comes to replace the normal wear and tear that occurs over time on your WAZER cut bed.

| List Price: | $299.00 |

|---|---|

| Price: | $199.00 |

| Price: | $... |

| Order Now: | Processed Immediately Free U.S. Shipping |

Wear and tear naturally happens over time with repeated use on any manufacturing machine's consumable parts.

The WAZER Cut Bed extends its cutting life thanks to its 4-inch thickness made of finely corrugated polypropylene plastic with top and bottom surfaces heat welded together (to ensure flatness). It's also reversible for usability on both sides, further extending its lifespan. The Cut Bed is also oversized for an additional fastening border. The grid pattern acts as a visual aid and reference indicator so you can easily adjust the placement of your material in your WAZER to match your file placement in the Wam software.

Replacing the WAZER Cut Bed is easy and only needed when you do not have sufficient support or fastening points for the materials you would like to cut.

What's Included with the WAZER Cut Bed (3 Pack)?

- 3 x WAZER Cut Bed

What are the Technical Specifications of the WAZER Cut Bed?

- Dimensions (L x W x H): 13" x 19" x 4" (per bed)

- Weight: 6lbs (per bed)

- Material: Corrugated polypropylene sheets

- Reversible: Yes

- Est. Lifetime: 20 - 100 hrs (per bed)

- This estimates both sides

- Lifespan varies depending on geometry being cut

- Additional Features:

- Top and bottom surfaces heat-welded for flatness

- 3” x 3” Grid Pattern acts as reference indicator matching WAZERcam software

- Est. Operating Costs:

- 1-Pack: $0.01/min

- 3-Pack: $0.01/min