3D Printing Essentials: How to Perfectly Level your Bed

For some, levelling a 3D printer's bed can be challenging, but it doesn't need to be. Read this essential guide to see what it takes to do it right.

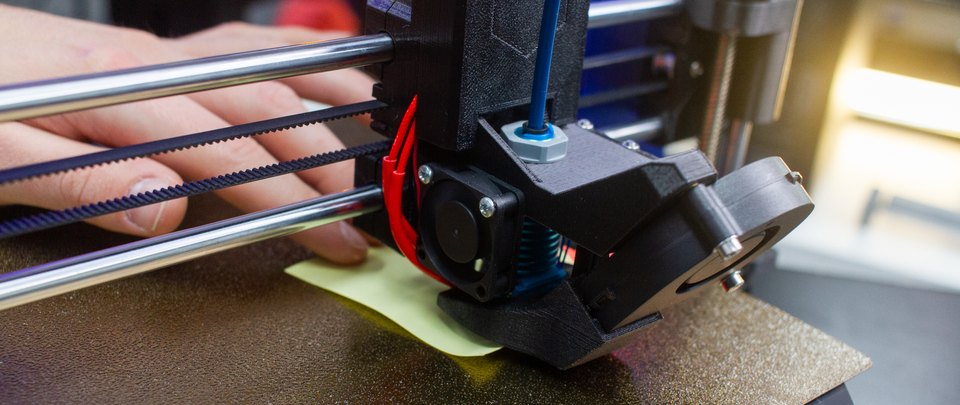

Part of the 3D printing experience is having an acute understanding of how the machine works and how to properly calibrate it to give you the best chance for success. Making sure that the first layer of every 3D print is the ideal distance from the bed isn’t the only factor in your 3D print’s success–you also need to ensure your 3D printer’s bed is universally level. Your first layer may look perfect in the front of the bed, but it’s also important to consider how well it’s sticking in the back of the bed as well. Leveling the bed of your 3D printer is an important step in getting high quality 3D printed parts, but it can be a little tricky. Luckily, the Pros at MatterHackers are here to help. Let’s take a look at the essential lessons of leveling your 3D printers bed.

What Does It Mean to “Level a 3D Printer’s Bed”?

First, there is the important distinction that what is colloquially referred to as “leveling your bed” would more accurately be called “tramming your bed.” The goal is not to have the bed level in relation to the floor (as you might imagine doing with a bubble level), but rather to have the bed be the same distance from the nozzle across the entire surface of the build plate OR put differently the bed parallel to the printhead gantry. This in fact might mean that if you take a bubble level to your 3D printer’s bed, you will probably find that it’s skewed. However, start a 3D print that runs across the entire bed and you’ll see the first layer is perfectly flat.

Simply put - leveling your printer’s bed is exactly as it sounds. You want to make sure your bed is level so there is a precise distance between the nozzle and the entire surface of the build plate. Now, you can’t just put a standard bubble level on your bed and call it a day, because again, the “level” we are looking for is between the nozzle and the print surface - not the nozzle and the workbench, desk, or floor that your printer is sitting on.

Manual Bed Leveling

In terms of construction, manually leveling, or adjusting your printer’s bed by hand, is the simplest form of bed leveling you will find on a 3D printer. Generally, the more affordable the 3D printer is, the more likely it will be a manually adjusted bed because it doesn’t require any complex calculations or extra hardware to make it work. A manually leveled bed will have the build plate itself floating above the bed carriage–it is not rigidly mounted to the bed carriage. Instead, the build plate is secured to the carriage using a combination of screws, springs, and thumbscrews. This combination makes it so the bed can pivot and be adjusted while still being rigid enough to not bounce around while you are 3D printing.

How to Manually Level the Bed

Three points define a plane, but many printers still use four screws to level the bed, with one at each corner.

- Tighten down all the screws at each corner, so you have enough room to loosen them later. Aim for screwed down halfway instead of all the way or all the way off–this will give you more room to work with.

- Home the Z axis.

- On some printers, Z0 (home) may be too far from the bed, even when all the screws are loose. In that case, you’ll need to move the Z-minimum endstop slightly lower to calibrate.

- Using the LCD menu or other interface, jog the printhead over each screw that levels the bed, insert a piece of paper between the nozzle and the bed, and loosen the screw until there’s a very slight resistance when you pull on the paper.

- You don’t want the piece of paper to be locked between the two, just enough pressure to feel the drag when you move the paper.

- Repeat this for the other screws.

- You want to make sure each screw pinches the piece of paper with the same amount of pressure to have a level bed.

- After adjusting all screws, check your work by moving the nozzle over the screws again and making sure they didn’t shift from previous adjustments.

- Start a print.

- You can make adjustments while the 3D printer is printing to fine tune your first layer.

Once your printer is leveled, it should stay that way for a while. However, it’s a good idea and maintenance practice to adjust or relevel your printer’s bed occasionally to ensure great prints every time.

Software Leveling

Ideally, manually adjusting the bed is enough to have a consistent first layer. However, depending on the quality of components used on a 3D printer, a bed may not be a uniformly flat surface to start with. In some cases, thinner 3D printer beds have a tendency to bow and warp as they heat up and cool down which means no matter how hard you try there will always be some point on the bed that will be lower or higher than the rest. Effectively, no amount of thumbscrew adjustment will compensate for a 3D printer with a bed shaped like a bowl unless you have some compensation routine, like software leveling.

What is Software Leveling?

Within MatterControl, our slicing software, there exists a guided wizard that will allow even the most extremely out of shape printer beds to have a uniform first layer. By manually mapping the bed of your 3D printer, MatterControl is able to adjust the Z values in the sliced Gcode so the nozzle is constantly moving up and down to achieve a consistent distance from the bed throughout the 3D print.

How to Software Level.

You will need to connect your 3D printer directly to MatterControl by connecting the USB from the printer to your PC. Once the leveling is complete you can continue to 3D print from MatterControl or export the sliced Gcode onto an external device like an SD card or thumb drive.

- Connect your 3D printer to MatterControl.

- Under the “Controls” tab and “Calibration” subsection click “Printer Calibration”

- Follow the wizard

- Your printer will then home on X, Y, and Z and then move over the first point that needs to be calibrated.

- Insert a small piece of paper between the nozzle and the bed and slowly decrease the distance between until you feel a very slight resistance on the printer.

- Not enough to hold the paper tight, but enough to feel that it can’t easily slide around anymore.

- Repeat this process for every point of the grid until a mesh can be constructed.

- The most important thing is to have the resistance of the paper the same at every point so that it is uniform. A little too tight is fine as long as you use this measurement throughout the bed.

- Slice up a test print to check your work.

- A large rectangle that covers the bed will make it clear if any point is too close or too far at that particular point.

- Adjust the Z-Offset by baby-stepping further or closer to the bed.

After it’s all said and done, your bed itself won’t be level but your first layers will have a consistent distance from the bed which means your 3D print’s foundation will be adhered to the bed and lead you on the path to success. Be sure to run through this wizard again if you find that you are experiencing high or low spots in your first layer or adjust the number of points you have in your mesh grid if the trouble spots are between probe points.

Firmware Leveling

On some 3D printers, user intervention is kept to a minimum by a handful of features built into the firmware of the 3D printer, hard-coded into it to make finding the perfect first layer as hands-off as possible. By using a small probe to detect the bed and its relative distance from the Z minimum or Z maximum, the firmware is able to automatically run through a bed leveling procedure and construct a grid that will compensate for an uneven bed. Think of firmware leveling as essentially the same thing as software leveling, except the printer is doing all the thinking instead of you and a piece of paper.

How to Firmware Level the Bed:

If your 3D printer has firmware leveling, it is likely enabled by default, rather than something you turn on if you want it. The best practice is to follow the instructions prescribed by the manual included with your 3D printer. Most 3D printers with firmware leveling will have a wizard (a guided walkthrough) incorporated into it to make set up easier. In general, the process will be similar across the different 3D printer and probe types:

- The nozzle and bed will heat up in order to allow them to expand and get a more accurate reading.

- The print head will move around the 3D printer probing various points to create a mesh of the detected surface.

- Either a series of lines will be printed to determine which Z-Offset works best, or a small test print will need to be started manually.

- The Z-offset will be adjusted through the LCD menu to move the nozzle closer or further from the bed to achieve a proper first layer and determine the distance between the probe tip and the tip of the nozzle.

Firmware leveling is a straightforward process that aims to simplify what used to be a significant hurdle for newcomers to 3D printing. By integrating automatic systems, it becomes easier to have repeatable results. Spend less time worrying about your 3D prints you just started and more time focused on slicing up your next one. There are many different probes that can be found on 3D printers, and you can check out our article on the different types to see what kinds of limitations, if any, your probe might have.

Whether you have a 3D printer that needs to be manually leveled or a 3D printer with fully capable firmware leveling, it’s important to understand the basics of how the process works to troubleshoot and calibrate your 3D printer as you become more acquainted with it. Hopefully, with the help of this guide, you now understand how to level your bed and get smooth and consistent bottom layers on your 3D prints. With this knowledge, you are well on your way to understanding the 3D printing essentials.

Happy printing!

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.