How To: 3D Print Nylon on Garolite Print Beds

If you’ve ever printed with a high temperature material, you’ve probably found that there’s some difficulty in getting your parts to stick to the bed.

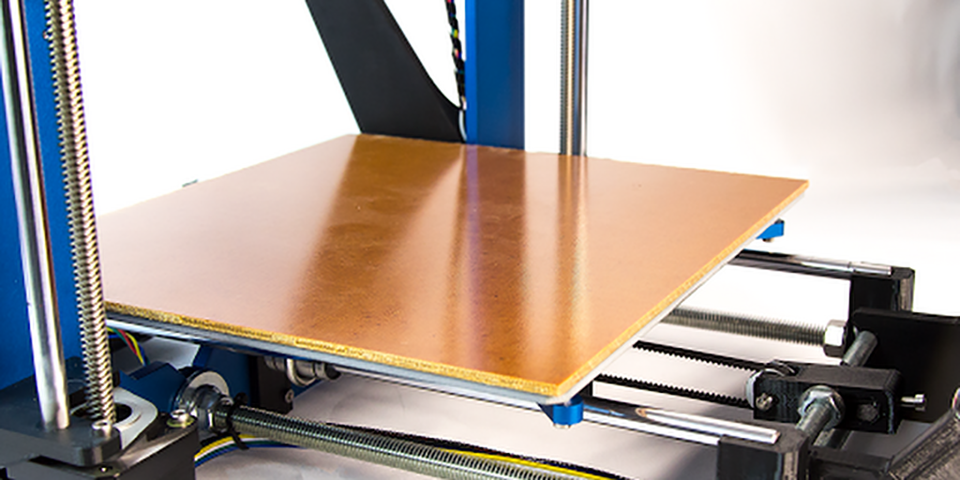

If you’ve ever printed with a high-temperature material, you’ve probably found that there’s some difficulty in getting your parts to stick to the bed. Some higher-end 3D printers don't have a heated bed and can print nylon beautifully, and that’s due to the unique properties of their garolite bed.

Where Can I Get Garolite?

If you're looking for a 3D printer that comes stock with a garolite bed, the Pulse XE is for you. The Pulse XE is a printer system designed to print NylonX successfully out of the box, and part of that is due to the garolite that is attached to the bed. The bundle we offer with the Pulse XE is an especially great deal for those interested in printing with NylonX as this bundle comes with 2 spools of NylonX and a PrintDry at a reduced price.

If you're looking to add garolite onto a 3D printer you already have, then look no further than our LayerLock Garolite Build Surfaces page. For a long time, garolite wasn't seen very often but now it's pretty easy to find a sheet of it online. However, there are many different types of garolite sheets out there and not all of them are compatible for the specific purpose of 3D printing. To take the guesswork out of whether or not you're buying the correct sheet of garolite, we offer thin garolite sheets of various sizes for compatibility with various 3D printers over at our LayerLock Garolite Build Surfaces page. The sheets we offer are 3D printer friendly and guaranteed to help you succeed with your 3D printing endeavors.

Attaching the garolite sheets we offer is super easy. These 0.038" thick sheets with an adhesive backing allow users the flexibility to stick garolite onto any existing build plate you have thanks to its thin size requiring very little adjustment to your printer's settings. Simply remove the adhesive liner on the back, attach the sticky back to your clean build plate, and you're done with installation! Before you start printing away, there are some steps you'll want to take in printing on garolite to avoid damaging it.

Step 1 - Adjust Bed Temperature

First off, while you can print nylon or PETG on garolite without heat, it does help to have a little bit of heat just like PLA. A bed temperature of 65C works well for both nylon and PETG.

Step 2 - Adjust Nozzle Height

Before you start printing any big parts, you’ll want to do a couple calibration cubes to optimize your Z offset. Parts can stick so well to garolite that it will actually fuse to it and you’ll need a razor blade to remove the part and the chunks of garolite stuck to the print. I’ve printed a NylonX Phil on garolite too close and had him fuse to it completely, breaking him apart and leaving just his boots stuck to the bed. Start with a Z offset higher than you might normally use and progressively lower it until the print starts sticking to the bed without warping. It’s better to start too far away than too close for the aforementioned reasons.

Step 3 (If Necessary) - Use PVA Glue

If you’re finding prints aren’t sticking despite your best efforts, you can use PVA glue on the bed to give it a little extra hold as well as 220 grit sandpaper to add some texture to the bed surface for your print to grab onto. You do need to be careful on your choice of glue stick, because some "school glue sticks" are actually not PVA and don't make mention of it on their labels. Elmer's school glue sticks are a safe bet and come stock with LayerLock Garolite Build Surfaces. A small square sheet of 220g sandpaper is also included.

That’s about all there is to it. Printing on garolite makes high-temp material printing a lot easier without much difference in your normal 3D printing routine. Of course, if you're attempting to print materials than need more heat than nylon, you might be looking for a more advanced printer to handle those materials, specifically one that uses an enclosure.

I hope this helps anyone looking to print high temperature materials or are looking for ways to upgrade their printer's material capabilities. If you have a tip for printing on garolite, please leave a comment! I'd love to keep this article up to date with all the best practices people have found.

Happy printing!

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.