Top Ten Upgrades for your 3D Printer

We have compiled a list of ten different upgrades you can add or modify your 3D printer with to increase its performance and capabilities.

Today we’re going to talk about upgrades. 3D printers are a technological marvel, but even still some of us have that itch to make them even better. Just like a car has a million parts working together to move nearly two tons, people still have that need to tune it, change out some parts, and make a beast of a machine that they’re proud to call their own. There are some upgrades for 3D printers that are simple and won’t take much work to install - no more than undoing a couple of screws or removing it from the packaging, while others will need some firmware changes, or 3D printing new mounts to fit these parts together. I’ve compiled a list of ten different upgrades you can add or modify your 3D printer with, so let’s get to it!

Motor Dampers

These little things can make a huge difference in the volume of your 3D printer while you’re 3D printing. They work by decoupling the motors from the frame with a small piece of rubber, minimizing the vibrations of the motors resonating throughout the frame. The only change you should need to make is adjusting the set screw on the drive pulley so the belt path stays straight; the damper spaces the motor a couple of millimeters away from the frame. These do have directionality to them - this ring gives you space for the top of the motor, but other than that you can turn these whichever way provides easier access to the screws for install. Just make sure that two screws hold the damper to the motor, and two hold the frame to the damper; don’t have the screws go all the way through the frame, damper, and to the motor, as that will completely negate this upgrade.

Buildtak Flexplate System

I used to print exclusively with glass build surfaces on all the 3D printers I used, with hairspray or gluestick. I preferred being able to really attack my prints with a spatula if I needed to, rather than fearing I would damage any adhesive sheet if a print stuck too well. Until I was shown the Buildtak Flexplate System. I could have a print finish, barely flex to spring steel and the part pops off, then put the sheet back and start the next print without having to wait for any cooldown. I even have different Flexplates I can swap around depending on what I’m printing, like Layerlock Powder Coated PEI for PLA, Layerlock Garolite for nylons, or Buildtak and PEI for general purpose printing. And while you can have them double-sided, it’s best to do that with thinner material to ensure enough strength between the magnet base and the spring steel.

MatterHackers 3D Printing Premium Tool Kit

Having a set of tools specifically for your 3D printer is a great quality-of-life upgrade. In the tool bag, you have a variety of tools for maintenance, post-processing, and assembly of your 3D prints. The adjustable screwdriver, deburring tool, and nozzle cleaning kits are my favorites included in this set. I do a lot of assembly with hex head screws, and having a true screwdriver rather than a regular hex wrench is a lot more comfortable and easier to apply pressure when driving a screw. The deburring tool is great for cleaning off any elephant foot where the first layer was just a little too squished. Nozzle clogs happen, and having a little needle you can gently use to break up the clog is a lot handier than you’d expect.

BL-Touch Automatic Bed Leveling Probe

What a lot of new users aren’t used to when they first start 3D printing is getting that first layer just right. Either prints are much too close and elephant foot or are too far and barely even stick to the bed, or it’s a combination and parts are too close on one side but too far on the other. This is a combination of two things: a level bed and the right distance from the nozzle. A BL-touch solves these two things. Installing one does require printing some new mount for your 3D printer’s tool head and will require some changes to the firmware for it to know what to do with it. You can find a ton of different variations in BL-Touch mounts on all the File Repository websites, and usually, there’s the inclusion of the firmware they used on their printer. A BL-Touch works by having a small pin that drops down, and the print head is moved closer to the bed until it gets close enough and pushed the pin in, where it gets close enough to a magnet to pull it in and engage a switch. This sends to the printer’s main board that the bed is at some Z value at this location and then repeats this across some predetermined grid. The bed can be completely tilted, but once it starts printing, the Z motors will constantly turn to make sure that the nozzle is always the same distance from the bed. When you install the firmware, the Z-Offset will need to be calibrated, which tells the printer that “yes, the probe triggers here, but that’s actually still 2mm above the bed” so it knows that when everything’s done, it moves the nozzle the right distance.

E3D V6 or Mosquito Hotend

Changing the hotend of your 3D printer requires a couple of things: some changes to your firmware, some calibrating and printing out some new parts, but depending on your printer, it can have some serious payoff. Both of these hotends are all-metal, which means the maximum temperature you can reach jumps up to 300°C from the 245°C that’s achievable with PTFE hotends. As Slice Engineering is newer to the scene, there aren’t as many mounts out there, but E3D has plenty of available mounts you can find out there. And for some printers, these hotends are significantly easier to service if than the stock hotends which can have proprietary parts you can only get for that printer.

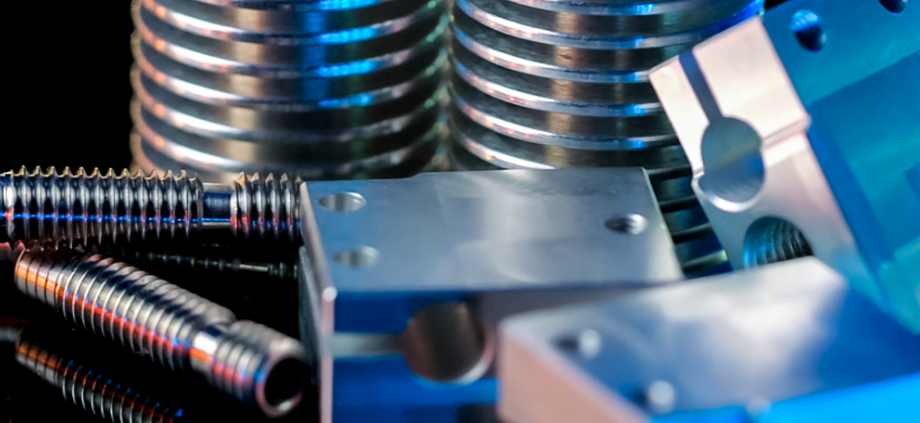

New Nozzle Upgrade

If your printer uses M6 threading for the nozzle, then you can drop in some of the best nozzles on the market. Having a higher quality nozzle brings you more material capabilities and more consistent performance. On the more affordable side of things is a simple hardened steel nozzle - where brass wears away rapidly with carbon fiber infused filaments, hardened steel will last a long time. E3D’s Nozzle X is made from tool steel, which is much stronger than hardened steel and even has two coatings: one for temperature and abrasion resistance and the other to keep filament from sticking to the surface. E3D trusts their nozzle so much that if you can turn your 0.4mm nozzle into a 0.45mm nozzle, they’ll replace it (as long as it wasn’t from ramming the bed or anything like that). The Olsson Ruby is another great option with its genuine ruby in the tip for ultra wear resistance. In addition, because it’s made of brass, it still retains great thermal conductivity.

Extruder Upgrade

A lot of the hobbyist-level 3D printers come with extruders that are just barely good enough to get the job done. However, installing something like a Bondtech or an E3D Titan can be a game changer. The E3D Titan and Bondtech extruders are geared extruders with adjustable tensioners and a constrained feed path, so you can fine tune things to work perfectly for any exotic material you try printing with. The gearing gives the extruder more torque, the tensioner prevents grinding from too little tension on the filament, and the constrained path means printing flexible. Both are capable of being set up as Bowden or direct drive, but the Bondtech has the added bonus of having “dual-drive gears” so there are teeth on both sides of the filament gripping and pushing it to the hotend.

Heater Cartridge

If you’re like me and find yourself wanting a PrintCore-esque system like what a lot of the high-end printer companies have, the heater cartridge is usually the only electrical component on the hotend that doesn’t have a quick disconnect - unless you use E3D’s 30W Precision Heater Cartridge. This comes with the quick disconnect already installed, and the precision isn’t just from the 30W being truly 30W, but from the precision machining for the casing, making sure that the heater cartridge contacts the heater block on all sides for optimal heating.

3D Printer Enclosure

An enclosure can make the difference between a successful print and a bird’s nest; ABS is notorious for its potential to warp away from the bed and otherwise ruin a fantastic print. This usually comes from the bed being too cold, a layer cooling fan is too strong, a sudden gust of wind, AC, or a draft as you walk the printer, or it’s just plain too cold in the room the printer is in. While some printers are pretty enclosed by design, others need a little help to get there and that’s where a full enclosure comes in. While you can build one yourself using some insulation foam, cardboard, or even just a trash bag, there also exists some precut kits that are designed for the shape and features of specific printers to help keep the hot air in and keep the cold drafty air out. These also include some punchouts so you can move the electronics like the power supply, control board, or LCD outside of the enclosure or even spots to install a fan and filters.

Mosaic Palette 2 Multi-Material Filament System

For the power users, there’s the Mosaic Palette 2: a multi-extrusion setup. Mosaic has some prebuilt profiles for some printers out there, but depending on what you have, you can set this up with any 1.75mm printer, you’ll just need to do some calibrating yourself. It works by feeding in four filaments and splicing them together to form one strand of filament, then regularly checking that the splices haven’t gotten out of sync with the actual prints. With the Palette 2 you can do up to four colors in the same part, or use the inputs for different materials, incorporating rigid filament, flexibles, and support material all in one print. Having a method for multi-extrusion opens up your possibilities for your designs.

Upgrading your 3D printer isn't required to get a successful 3D printing experience, but depending on the hardware included with your stock printer, it can certainly be a boost in its performance. What's hard to beat is a printer that you can throw almost any material at and trust that it can get the print job done successfully and repeatably. I hope that this has given you some ideas and some direction on where to take your 3D printer next to bring it to its best capabilities. Is there some upgrade you've done that you feel should be on this list that wasn't? Let me know in the comments and I may revisit this topic.

Happy upgrading!

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.