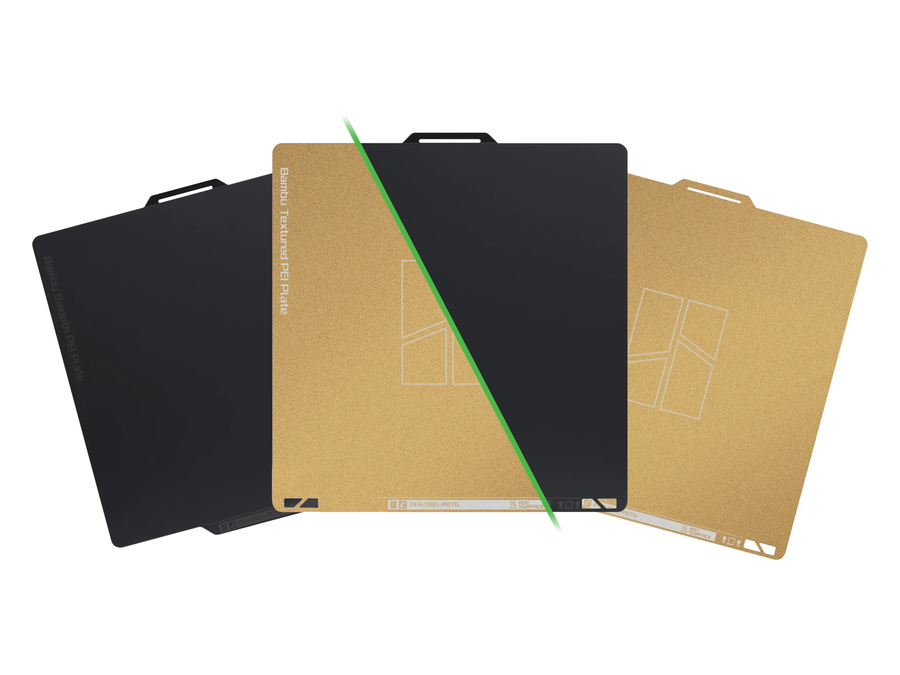

Bambu Lab Bambu Build Plate

Bambu Lab offers a variety of build plate options for 3D printing applications, each designed to succeed with multiple materials. Bambu build plates deliver excellent adhesion and easy print removal with a flexible plate.

- Variety of plate options

- Compatible with multiple materials

- Flexible plate for easy removal

- Enhanced first-layer appearance: smooth matte or rugged texture

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

BAMBU BUILD PLATE

EXCELLENT ADHESION & EASY PRINT REMOVAL

Bambu Lab offers a variety of build plates that specialize in succeeding with multiple 3D printing filaments on your Bambu Lab 3D printer for a superior additive manufacturing experience.

Key Features of the Bambu Lab Build Plate:

- Variety of options available

- Easy print removal with flexible plate

- Delivers excellent adhesion

- Enhanced first-layer appearance

- Smooth matte w/ Smooth Plate

- Rugged texture w/ Textured Plate

SMOOTH PEI

HIGH Z-Axis Precision Printing

The refined texture of smooth PEI beds contributes to superior Z-axis precision during printing operations, yielding more consistent and accurate vertical dimensions.

Smooth and Matte Surface Finish

Enhance your print's overall appearance with this specially selected matte PEI sheet that imparts a smooth and matte texture to the bottom surface of the printed object.

TEXTURED PEI

Excellent First-layer Adhesion and Durability

Adhesion between the prints and the plate on the Bambu Texture PEI Plate is excellent, eliminating the need for adhesives for most situations. Additionally, powder coating provides an enhanced layer of durability that sheets can't.

Self-Release on Cool Down

PEI withstands the repeated heating and cooling cycles of a printer heatbed, making it a go-to staple for 3D printing applications. Prints come off easily when the temperature of the heatbed reaches room temperature (≤35°C). If the print still adheres to the plate, give the plate a bend and the model pops right off.

BEST OF BOTH WORLDS

Can't decide between first-layer textures? Enjoy printing in all sorts of materials? Pick up the Bambu Dual-Texture PEI to get the best of both surfaces.

- Smooth

- Print PLA with minimal prep

- Enjoy smooth, matte first layer

- Textured

- Print other materials with no additional adhesive (for most materials)

- Enjoy rugged texture first layer

Which Bambu Build Plate is Right for Me?

| Smooth | Textured | Dual-Texture PEI | |

| Ideal Use Case |

✓ Printing mainly PLA ✓ Desire a smooth first layer |

✓ Printing mostly materials that aren't PLA ✓ Desire a textured first layer |

✓ Printing mainly PLA and other various materials ✓ Alternate between different first layers of your choice |

| Compatible Materials |

PLA, ABS, PETG, TPU, PC, PA (Nylon), PVA + Continuous Fiber variants |

PLA, ABS, PETG, TPU, PC, PA (Nylon), PVA + Continuous Fiber variants |

PLA, ABS, PETG, TPU, PC, PA (Nylon), PVA + Continuous Fiber variants |

| Note(s) | - Needs glue stick/liquid for all compatible materials except PLA |

- Upper glass cover plate must be removed for PLA, TPU, and PVA1 - Calibration sensitivity2 |

- Smooth side requires the least prep for PLA - Textured side does not require adhesive for most other materials - See Smooth & Textured notes for additional considerations and Settings for material specifics. |

1 The upper glass cover plate needs to be removed for filaments with a low glass transition temperature such as PLA, TPU, and PVA.

2 Repeatedly rub the nozzle in the special wiping area of the build plate to completely remove any residual material at the tip of the nozzle. This ensures residuals on the nozzle do not decrease accuracy during calibration.

What are the Recommended Settings?

Note that other slicer settings might need to be adjusted based on the printed model and the filament requirements.

| Smooth | Textured | (Textured Only) | ||

|---|---|---|---|---|

| Material | Heatbed Temp | Glue Liquid / | Stick Required? | Upper Glass Cover Plate Removed? |

| PLA / CF* / GF* | 45 - 60°C | No | No | No |

| PETG / CF* | 60 - 80°C | Stick / Liquid | No | No |

| ABS | 90 - 110°C | Stick / Liquid | No | No |

| ASA | 90 - 110°C | Stick / Liquid | No | No |

| TPU | 35 - 45°C | Stick / Liquid | Stick | No |

| PVA | 45 - 60°C | Stick / Liquid | No | Yes |

| PC / CF | 90 - 110°C | Stick | Stick | No |

| PA / CF* / HT-CF* | 90 - 110°C | Stick | Stick | No |

| PET-CF | 80 - 100°C | Stick / Liquid | No | No |

What Are the Installation Steps for the Bambu Build Plate?

Step 1 - Align

Align the plate along the fixed points of the platform with the name of the plate facing you.

Step 2 - Lower & Secure

Lower the plate and secure it to the magnetic platform.

Notes

SMOOTH SURFACE

- If bubbles appear on the bottom of the sheet, heat it on the heatbed at a temperature of no less than 80°C for several hours to help eliminate the bubbles.

- Smooth PEI Plate only (does not apply to Dual-Texture Plate)

- On the Bambu Lab A1, there is a higher risk of the plate curling from the corners or printed models detaching from the plate. This is caused by the thicker Smooth PEI applied to both sides of the plate, which will increase the distance from the bed magnets and lower the magnetic attraction.

TEXTURED SURFACE

- Increasing heatbed temperature enhances adhesion. Adjust the temperature of the heatbed based on your specific requirements to achieve the most suitable level of adhesion.

- Before auto-leveling, it's necessary to repeatedly rub the nozzle in the special wiping area of the build plate to completely remove any residual material at the tip of the nozzle. The coating in the specially designed wiping area will gradually become worn over time. This is normal and does not affect print quality or nozzle lifetime, so there is no need to worry about any quality issues.

- The latest firmware brings significant improvements to the Bambu Textured PEI Plate calibration using the Micro Lidar, and it is now fully compatible with the automatic calibration process.

BOTH SURFACES

- Dust and grease decrease adhesion on the build plate. Regularly clean the surface with detergent and water to maintain the best adhesion.

- Do NOT clean the PEI build plates with Acetone. It will damage the PEI surface.

- Bambu Lab recommends only using Bambu Lab official glue on the Bambu Lab build plates, and can not be held responsible for any damage caused to plates due to using third-party glue on build plates.

- Carefully sanding the surface with fine-grit (600) sandpaper can help restore adhesion.

- Always wait for a few minutes before removing printed models to allow the plate to cool down for easy print removal. This prevents damage to the plate and ensures a long lifetime of the product.

- Bambu Lab build plates are considered a consumable part, which will degrade over time. The warranty only covers manufacturing defects, not cosmetic damage like scratches, dents, or cracks. Defective sheets upon arrival are the only instances covered by the warranty.

What Are the Tech Specifications for the Bambu Build Plate?

| Plate | Smooth | Textured | Dual Texture |

| Material | Smooth PEI Sheet + Stainless Steel Plate |

PEI Powder Coating + Stainless Steel Plate + Smooth PEI Sheet |

PEI Powder Coating + Stainless Steel Plate + Smooth PEI Sheet |

| Magnetic Plate | ✓ | ✓ | ✓ |

| Surface Temperature Resistance |

Up to 120°C | Up to 180°C | Smooth - ≤120°C Textured - ≤180°C |

| Stainless Steel Thickness |

0.5/0.4mm | 0.5/0.4mm | 0.5/0.4mm |

| Sheet / Powder Coating Thickness1 |

0.125mm | 0.075mm | Smooth - 0.125mm Textured - 0.075mm |

| Usable Print Size | 350 × 320mm 256 × 256mm 180 × 180mm |

350 × 320mm 256 × 256mm 180 × 180mm |

--- 256 × 256mm 180 × 180mm |

| Package Size | 408 × 388 × 17mm 300 × 270 × 17mm 220 × 190 × 15mm |

408 × 388 × 17mm 300 × 270 × 17mm 220 × 190 × 15mm |

--- 300 × 270 × 17mm 220 × 190 × 15mm |

| Package Weight | 0.78kg (1.72lb) 0.45kg (0.99lb) 0.23kg (0.51lb) |

0.78kg (1.72lb) 0.45kg (0.99lb) 0.23kg (0.51lb) |

--- 0.45kg (0.99lb) 0.23kg (0.51lb) |

1 Smooth PEI is a sheet while the Textured PEI is a coating.