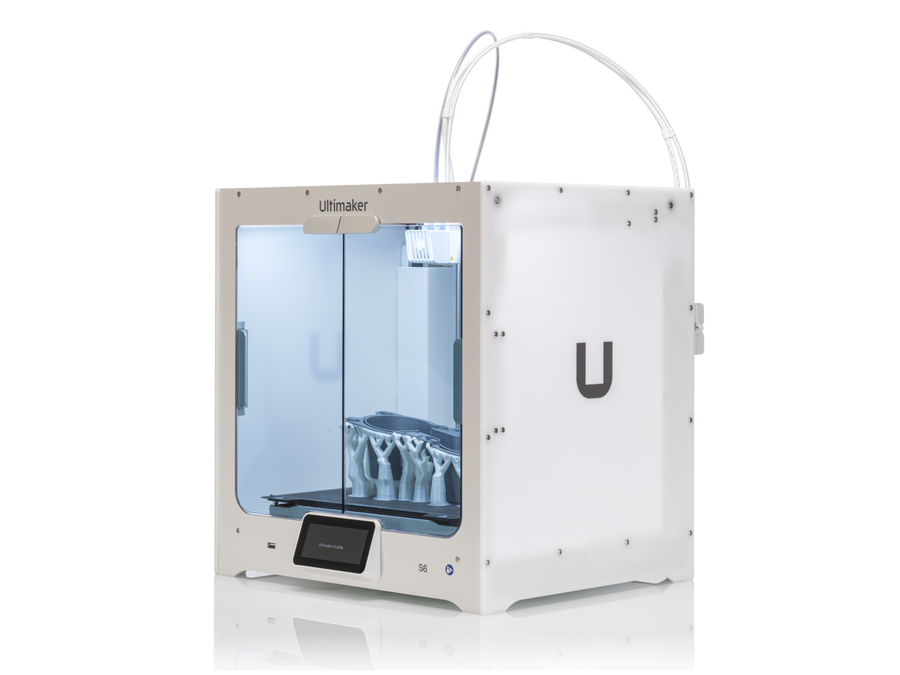

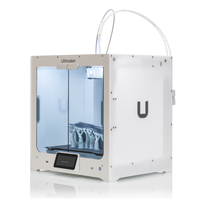

UltiMaker UltiMaker S6 3D Printer

With unprecedented 500mm/s speed and 50,000mm/s² acceleration, the UltiMaker S6 quadruples productivity while enhancing print quality. The revolutionary Cheetah motion system, advanced cores, and upgraded feeder create complex multi-material parts faster than ever through dual extrusion and open material compatibility. Experience the familiar security and reliability of S series printers with dramatically improved speed and precision—transforming your production workflow without compromising on the ease of use you expect.

- Accelerate production with 4x faster printing

- Ensure precision with 0.15mm layer accuracy

- Execute multi-material prints via dual extrusion

- Customize with a Material Station for Multi-Color prints

- Add an Air Manager to improve printing environment control

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

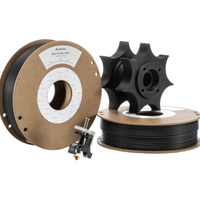

Upgrade to Carbon Fiber Printer for FREE

- 2x Spools of PET CF: High strength, high stiffness, and excellent heat resistance.

- 1x Print Core CC 0.60mm: Designed specifically to handle abrasive composite filaments with minimal degradation.

UltiMaker S6

INCREASE SPEED WITH ULTIMAKER CHEETAH

The UltiMaker S6 3D printer delivers exceptional productivity at up to 4x the speed of previous models while maintaining superior print quality (0.15mm ± 0.15%). Engineered with the advanced UltiMaker Cheetah motion planner, this professional-grade system accelerates production timelines, reduces operational costs, and enhances manufacturing capabilities. Its precise dual extrusion technology supports over 300 engineering-grade materials for complex applications, driving innovation and reducing time-to-market. The Pro Bundle configuration, featuring the Material Station, provides streamlined multi-material management for manufacturing environments requiring maximum efficiency without compromising reliability.

Key Features of the UltiMaker S6 3D Printer:

- Choose between glass plate for FDA compliance or flexible plate for convenience

- Reduced time-to-market for prototypes and production parts

- 4× faster productivity with Cheetah motion planner technology

- Superior print quality (0.15mm ± 0.15%), even at high speeds

- Dual extrusion capability for complex multi-material applications

- Built-in security features protect intellectual property

- Pro Bundle includes Material Station for streamlined material management

- Compatible with 300+ engineering-grade materials

Need to adhere to security requirements? Check out the Ultimaker S6 Secure Edition here.

VERSATILITY MEETS SPEED AND ACCESSIBILITY

Composite-Read Dual Extrusion |

330×240×300mm Build Volume |

Award-Winning Touchscreen UI |

Click & Print with the Advanced Materials |

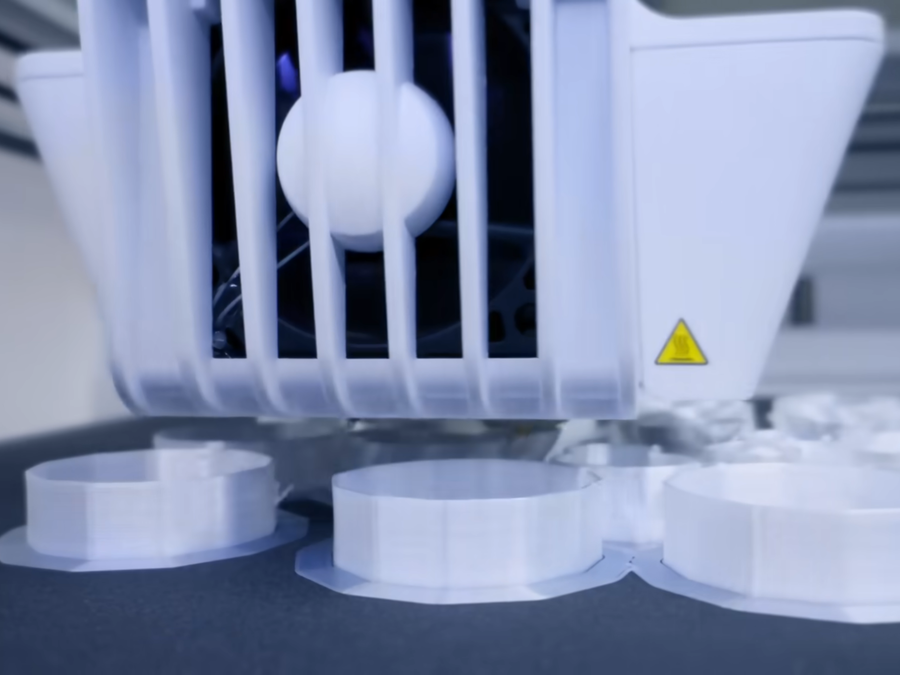

4X YOUR PRODUCTIVITY

Rapidly produce professional parts without sacrificing precision on the UltiMaker S6 3D printer. Built with the UltiMaker Cheetah motion planner, users can achieve unprecedented speeds by printing up to 4x faster while improving dimensional accuracy to 0.15mm ± 0.15%.

- Revolutionary UltiMaker Cheetah motion planner technology

- Up to 500mm/s print speed with 50,000mm²/s² acceleration

- Zero quality compromise for rapid production

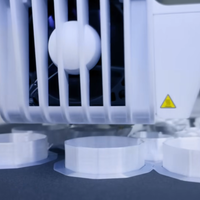

OPTIONS FLEXIBLE TO YOUR NEEDS

Designed to fit different workflows and requirements, the UltiMaker S6 offers two distinct build plate options. Glass plates prioritize meeting compliance in highly-regulated industries, and flexible plates enable printing convenience. No matter your application, UltiMaker S6’s build plate options ensure you have the right tool for the job.

- Glass plates for sterile, easy-to-clean FDA compliance

- Flexible plates for convenience and superior bed adhesion

- Mix and matching plates is unavailable

Advanced Hardware Innovations

Completely redesigned internals of the UltiMaker S6 3D printer feature quad-chamber print cores that deliver 2.5x more flow. New electronics allow 5x more processing power, creating a future-proof platform for years of performance improvements.

- 5x more processing power

- New AA+ and CC+ high-flow cores

- Future-proof for over-the-air updates

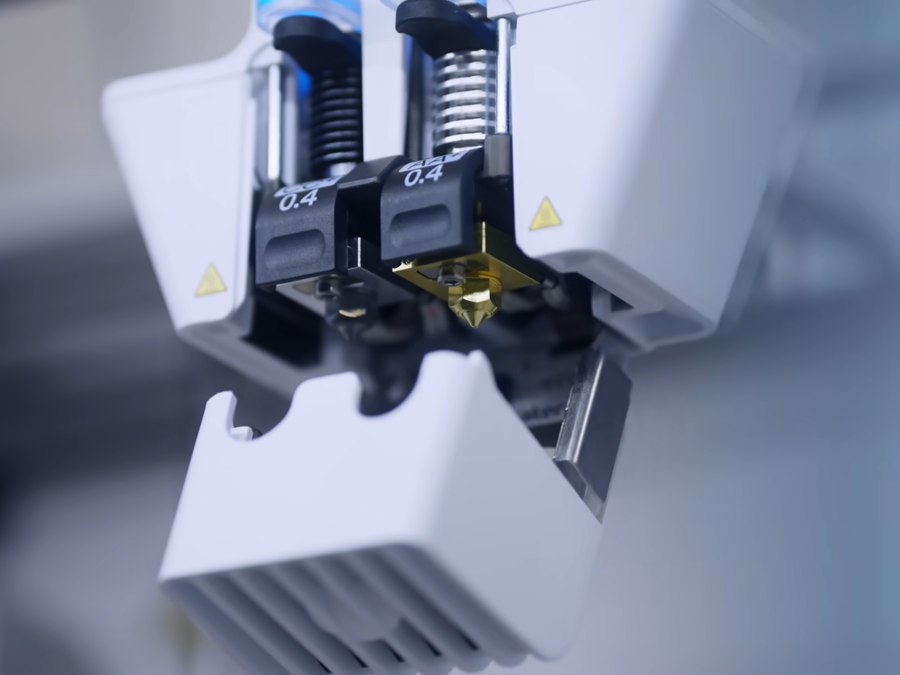

Industry-Leading Dual Material Capability

UltiMaker S6's dual extrusion system combines any two materials, enabling complex multi-material applications. Minimize waste and maximize reliability as you unlock new possibilities for functional parts and prototypes.

- Seamless combination of any two materials

- Complex geometries with different material properties

- Low material waste during transitions

- 300+ compatible material options

Onboard What You Need

In addition to choosing your build plate option, the UltiMaker S6 offers the option to onboard the printer only or set you up for success with the Pro Bundle option, which includes a multi-material handling station and air manager. Maximize your productivity and compatible materials with this equipment included in the S6 Pro Bundle.

- Choose printer only or bundle up

- Maximize your productivity with multi-material handling station

- Enhance material compatibility with air manager

Reliability Built on Experience

Drawing on over a decade of expertise, the S8 maintains UltiMaker's hallmark reliability. Push performance boundaries, ensure consistent results, and minimize downtime—even at accelerated speeds.

- Minimized failed prints and downtime

- Peace of mind for critical projects

- Industry-defining success rates w/ 10+ years of engineering experience

Open System with Integrated Ecosystem

As part of the world's largest professional 3D printing open platform, the UltiMaker S6 printer offers unparalleled flexibility while maintaining a seamlessly integrated workflow from software to hardware for optimal performance.

- World's largest professional open system

- Vertically integrated for professional workflows

- Continuous improvements via regular updates

- Mix UltiMaker and third-party solutions

Streamline Your Digital Factory

UltiMaker Digital Factory transforms 3D printing into a seamless, efficient experience—manage slicing, files, and maintenance all in one platform. Scalable for any team, it’s the smarter, faster, and more collaborative way to achieve your 3D printing goals.

- Streamlines every step of your workflow

- Scales effortlessly for teams and enterprises

- Enhances collaboration and project management

Secured, Defense-Grade S6 3D Printer

The UltiMaker S6 Secured empowers defense operations with rapid prototyping, in-field repairs, and secure, on-demand part manufacturing. Featuring open-material compatibility and advanced security features, the S 6 Secured enhances mission readiness while meeting stringent defense security standards.

TAA compliant and available through GSA contracts, the UltiMaker S6 Secured is fully approved and easily accessible for government and defense procurement.

Check out the secured version here

WHY BUY FROM MATTERHACKERS

MatterHackers is where digital fabrication technology meets passion. When you shop here, feel confident knowing that the vast selection of machines, materials, accessories, and unique bundles we've curated in our catalog are guaranteed top-quality products backed by our team of experts.

Exceptional customer service, fast & free shipping on orders over $35, a 30-day return policy, and more make us the reliable go-to for professionals, educators, and hobbyists. At MatterHackers, we're more than just a retailer; we're your trusted partner in production and innovation.

- Diverse, expert-curated catalog

- Top-notch customer service

- Convenient fast & free shipping

- Training and Maintenance Services

- 30-day Returns

- Rewards Program on qualified purchases

WHICH S-SERIES ULTIMAKER IS RIGHT FOR ME?

Determine which S-Series Ultimaker 3D printer is right for you using the table below, or request a quote for assistance from one of our expert Sales Representatives!

| UltiMaker S8 Starting at $8,999 |

UltiMaker S7 Starting at $7,999 |

UltiMaker S6 Starting at $6,950 |

UltiMaker S5 Starting at $6,950 |

UltiMaker S3 Starting at $4,450 |

| HIGHLIGHTS ✓ High Speed ✓ Perfect probing ✓ Large volume ✓ Fully enclosed ✓ Widest material compatibility ✓ Professional results |

✓ Perfect probing ✓ Large volume ✓ Fully enclosed ✓ Wide material compatibility ✓ Professional results |

✓ High Speed ✓ Perfect probing ✓ Large volume ✓ Modular ✓ Widest material compatibility ✓ Professional results |

✓ Large volume ✓ Modular ✓ Wide material compatibility ✓ Professional results |

✓ Entry-level ✓ Compact ✓ Professional results |

| ENCLOSED Fully |

Fully |

Partially |

Partially |

Partially |

| AIR MANAGER Integrated |

Integrated |

Optional |

Optional |

— |

| ULTIMAKER CHEETAH Yes |

No |

Yes |

No |

No |

| MAX NOZZLE TEMP Up to 340°C |

Up to 280°C |

Up to 340°C |

Up to 280°C |

Up to 280°C |

| COMPATIBILITY 301+ materials |

280+ materials |

301+ materials |

280+ materials |

190+ materials |

| EXTRUSION FLOW Up to 35mm3/s |

Up to 24mm3/s |

Up to 35mm3/s |

Up to 24mm3/s |

Up to 24mm3/s |

| BED LEVELING Automated |

Automated |

Automated |

Manual |

Manual |

| FLOOD DETECTION Yes |

Yes |

Yes |

No |

No |

| BUILD PLATE Flexible PEI |

Flexible PEI |

Glass OR Flexible PEI |

Glass |

Glass |

| # OF SPOOLS Up to 6 (with Material Station) |

Up to 6 (with Material Station) |

Up to 6 (with Material Station) |

Up to 6 (with Material Station) |

Up to 2 |

| BUILD VOLUME (mm) L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 330 (13") W: 240 (9.4") H: 300 (11.8") |

L: 230 (9") W: 190 (7.4") H: 200 (7.9") |

What are the Technical Specifications of the UltiMaker S6 3D Printer?

| PRINTER/PRINTING PROPERTIES | |

|---|---|

| Technology | Fused Deposition Modeling (FDM) |

| # of Extrusions | Dual Extrusion ✓ Auto-Nozzle Lifting System ✓ Flood Detection ✓ Inductive Probing |

| Filament Diameter | 2.85mm |

| Assembly | Fully-Assembled |

| Made in | Europe |

| Build Volume (XYZ) |

330 × 240 × 300mm (13" × 9.4" × 11.8") |

| Motion Planner | UltiMaker Cheetah ✓ Third order continuous algorithm ✓ Smooth motion algorithm ✓ Corner blending algorithm |

| Feeder Type | Dual gripper feeder ✓ Tension adjustment ✓ Release functionality ✓ Filament feed-rate control |

| Nozzle Temperature | Up to 340°C (644°F) |

| XY Speed, Acceleration, Jerk | Up to 500 mm/s up to 50,000 mm/s2 Up to 100,000,000 mm/s3 |

| Extrusion Flow | Up to 35 mm3/s |

| Dimensional Accuracy | ± 0.15mm ± 0.15% feature nominal length* |

| Layer Resolution | 60 - 300 microns (depends on the print core nozzle size and print profile) |

| Tool Head System | Hot-Swappable Print Cores |

| Compatible Print Core(s)** | INCLUDED AA+ 0.4 CC+ 0.4 SOLD SEPARATELY BB 0.4 DD 0.4 |

| Heated Bed Temperature | Up to 120°C (248°F) |

| Build Plate | Flexible PEI Plate OR Glass Plate |

| Build Volume Temperature (Enclosed) |

< 50°C (122°F) ✓ Open-loop temperature control |

| Operating Sound | < 50 dBA |

| Material Handling | PRINTER ONLY Dual spool holder with NFC recognition PRO BUNDLE Material Station 6-spool bay with NFC recognition |

| Material Station's Feeder Type (included w/ Pro Bundle) |

Dual-geared, Abrasion-resistant |

| Display | Fast, responsive color touchscreen |

| Monitoring | Full HD HDR camera |

| System On Module | ARM cortex quadcore at 1.8 GHz |

| Real-Time Controller | 600 MHz Arm-cortex M7 |

| Connectivity | Wi-Fi 2.4 & 5 GHz: IEEE 802.11a/b/g/n/ac LAN: Gigabit Ethernet USB: 2.0 |

| COMPATIBLE MATERIALS | |

| Easy to Print | UltiMaker PLA UltiMaker Tough PLA UltiMaker PETG |

| Reinforced Composites | UltiMaker PET-CF UltiMaker Nylon CF Slide LUVOCOM 3F PAHT CF 9742 BK Polymaker Polymide PA 12 CF |

| Mechanical Strength | UltiMaker ABS UltiMaker CPE |

| Heat Resistance | UltiMaker CPE+ UltiMaker PC Luvocom PAHT 9825 NT |

| Flexibility | UltiMaker TPU 95A Forward AM TPU 85A |

| Third-Party Material Compatibility | Yes |

| AMBIENT CONDITIONS | |

| Operating Temperature | 15 - 32°C (59 – 90°F) 10 - 90% RH non-condensing |

| Non-operating Temperature | 0 - 32°C (32 – 90°F) 10 - 90% RH non-condensing |

| PHYSICAL DIMENSIONS | |

| Dimensions (w/ spool holder) (W × D × H) |

PRINTER ONLY 19.5" x 23" x 30.7"

19.5" x 19.5" x 47.1" |

| Net Weight | PRINTER ONLY 20.6 kg (45.4 lbs) PRO BUNDLE 41.9 kg (92.4 lbs) |

| SOFTWARE | |

| Print Preparation | UltiMaker Cura 5.10 or newer |

| Printer Management | UltiMaker Digital Factory |

| OS Compatibility | MacOS, Windows, and Linux |

| Supported File Types | STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG |

| Output File Types | G, GCODE, GCODE.gz, UFP |

| WARRANTY | |

| Warranty Period*** | 24 Months |

* Typical accuracy based on selected geometries, materials, and randomly selected machines

** Legacy 0.25, 0.4, 0.6, 0.8 print cores can be used in combination with pre-sliced print jobs.

*** There is an optional add-on to include an UltiMakerCare Plan, on top of the 1-Year warranty that comes standard with all UltiMaker 3D printers, to provide additional/extended coverage of your investment.