3D Printing Essentials: Loading and Unloading Filament

Proper filament loading and unloading is a necessary part of 3D printing without trouble. Read on to learn the essential method you should be following.

3D printers have come a long way since they first started appearing on desktops around the world. As desktop 3D printing progressed, so too had the material choices for 3D printing; PLA, ABS, HIPS, nylon, TPU, PEEK—the list is almost endless. It’s important to know how to load and unload filament to prevent clogs, prevent color mixing, and ensure that finished 3D prints are at their peak strength by avoiding mixed material.

Automatic Filament Loading and Unloading

It should be straightforward how to load filament into your 3D printer, but if it is not, here are some guidelines on the different mechanisms used to set up your printer for receiving filament.

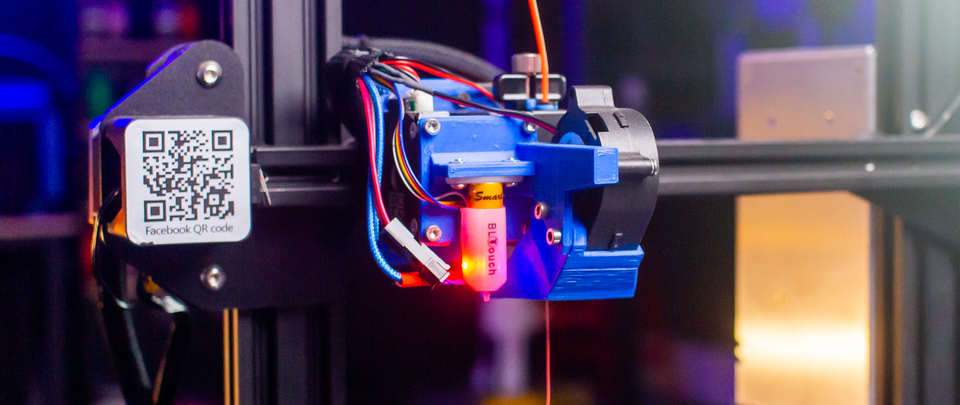

Some 3D printers make it easy with a “Load filament button” that enables you to load and unload material with the click of a button and automatic movement. This can either be done through the LCD of the 3D printer, or if there are “macros'' within a slicer, they will direct the extruder of the 3D printer to make preset moves to remove and insert filament. 3D printers like the Ultimaker S5 have pictures on the LCD to show you where to insert filament and lists to pick which material you are loading so it can heat properly. The Pulse XE utilizes macros within MatterControl to enable quick material unload and loading with minimal user intervention. For the advanced users, it’s possible to write your own macros as Gcode files that you can select to unload or load material; however, that requires an intimate understanding of that user’s 3D printer and the intricacies of the Gcode language. In any case, if your 3D printer features these loading and unloading abilities, it’s best to follow those steps closely rather than manually make changes.

Manually Loading Material:

Loading filament into a 3D printer is almost identical to unloading with a few easy caveats.

- Preheat the nozzle to the higher temperature between the material you are changing to or the material you are changing from.

- If you previously printed with NylonX and are changing to PLA, preheat to the printing temperature of NylonX to make sure it is completely purged from the nozzle.

- The printer will need to be brought to the right temperature to successfully feed the material in. Filament printing temperatures can vary widely between filament types and brands. You can typically find the accurate printing temperature specific to your filament either on the spool or the manufacturer’s website. If you don’t know or can’t find the printing temperature for the filament you want to load, here are some general good starting points for commonly used filaments:

- Snip the end of the filament with flush cutters at an angle. This will make it easier to guide the filament into the extruder path.

- Bend the filament slightly to straighten it out and prevent it from curling and missing inside the extruder.

- Relieve pressure on the extruder using the lever or loosening the thumbscrew and hold in place.

- With your other hand, insert the filament into the extruder.

- With a direct drive where the extruder is attached to the printhead, this will be done by feel until you can see filament extruding out the nozzle.

- With a bowden extruder, you will be able to see the filament enter the bowden tube and then easily push it through to the nozzle.

- Once the filament has reached the nozzle, readjust the tension.

- Through the LCD, extrude 100mm of filament to ensure that the previous material is adequately purge, or to transition completely from the previous filament to the new one.

- If your printer does not have an LCD or a way to move the extruder, you can force filament through the extruder by releasing tension in the same way you loaded filament. Simply push through roughly 100mm of filament by hand to accomplish the same effect.

- If you switched between two filaments that have completely different printing temperatures, remember to check that the nozzle temperature is set to match the filament it will now be extruding before printing with the material (i.e. if you switched from NylonX to PLA, make sure to set the printing temperature to PLA after the NylonX has been completely purged).

Manually Unloading Material:

For the 3D printers that need a more hands-on approach, unloading material manually is quick and easy once you know the right method.

- First heat up the hotend to the printing temperature of the material currently loaded. If you have PLA loaded, set the temperature to 200°C, etc.

- Release the tension on the extruder if possible. Some extruders utilize a small thumbscrew to compress a spring and apply more force on the filament, like the Bondtech BMG or the E3D Hemera. Others just use a small spring loaded lever that can’t be adjusted, in this case press down on the lever to relieve tension.

- With tension relieved, push the filament gently into the extruder until you see a small amount extrude out the nozzle.

- Quickly pull the filament out of the extruder. This should be done in a smooth motion, not a yanking one to prevent the filament from snapping. You should see the end of the filament will be slightly larger than normal, indicative that this part of the filament was in the nozzle and there isn’t any filament in the extruder path or bowden tube.

That’s all there is to it. Knowing how to change filament is a necessary part of the 3D printing process, and with the guidance presented here you should be on your way to 3D printing without any assistance. Every 3D printer is unique in its own way, so be sure to check any manuals or guide provided with your 3D printer initially before trying this all-inclusive method.

Happy printing!

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.