How to Succeed When 3D Printing with Polypropylene Filament

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

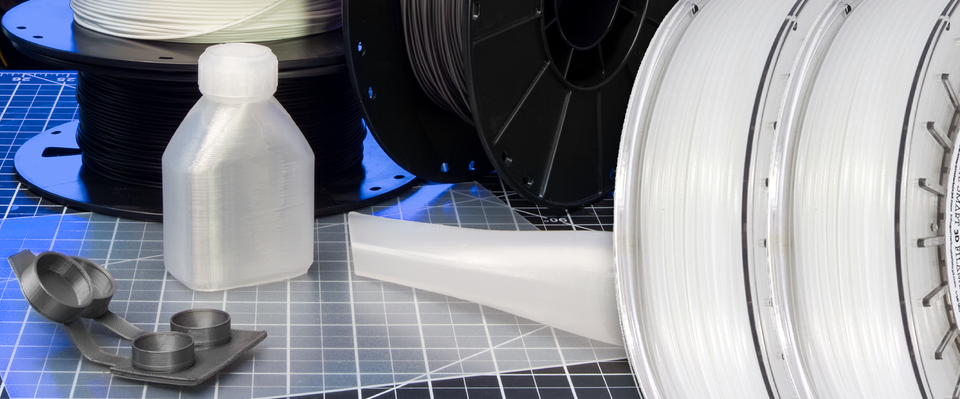

Polypropylene (PP) is a popular semi-rigid polymer material used to produce many common consumer products due to its superb mechanical properties. Suitable for a variety of applications, examples of everyday use cases can be found in the form of squeezable bottles, flip-top mint containers, car bumpers, toys, and so much more. Positive features associated with polypropylene include its robust resistance to chemicals, fatigue, high-temperature, and impact. This thermoplastic material is made up of hydrophobic molecules (molecules physically resistant to water), making it ideal for products that heavily rely on protection from moisture. With these qualities in mind, its no wonder polypropylene has caught the attention of 3D printing enthusiasts for prototyping purposes and even ready-to-use functional parts.

TABLE OF CONTENTS

- Polypropylene As a 3D Printer Filament

- Checklist for Success: Use the Right Tools

- How to Avoid Warping and Shrinkage

- Ready, Set, Print!

POLYPROPYLENE AS A 3D PRINTER FILAMENT

While not as commonly available as filaments such as PLA, ABS or PETG, polypropylene is slowly expanding its variety and availability in the market, and becoming more affordable for consumers. Hobbyists can expand their printing options as PP is a great practical option for producing prototypes that are lightweight, have water-tight tolerances, and are extremely durable. You will find that these qualities make this material especially ideal for prototyping household plastic containers. While this thermoplastic is technically both safe for microwaves and food contact, we do NOT recommend using prints made with Fused Deposition Modeling (FDM) 3D printers to store consumable food and liquids due to the porous nature of FDM 3D printing and possible cross-contamination when extruding this filament out of hardware that has not been labeled food-safe. Nonetheless, polypropylene is still a fantastic option for producing prototypes such as mechanical parts and containers with living hinges to store physical objects and liquids not intended for consumption.

3D PRINTING WITH POLYPROPYLENE

Producing parts with this material admittedly require a bit more finetuning compared to other filaments such as the fan-favorite PLA. That's where this handy how-to succeed guide comes in! All the tips and tricks we've uncovered from MatterHackers' engineers can be found here, so any hobbyist interested in expanding their 3D printing options can increase their chances of success. One crucial thing makers should be aware of is that this thermoplastic has a semi-crystalline structure that causes it to potentially warp and shrink upon cooling. Users must pay closer attention to settings that they may not normally consider in comparison to standard filaments like PLA. To avoid warping and shrinkage, check out the tips below on how to successfully produce polypropylene prints.

CHECKLIST FOR SUCCESS: USE THE RIGHT TOOLS

The first key to success is making sure you have the right tools. That means having the right 3D printer and accessories. With polypropylene, only a couple of upgrades are recommended if they do not already come stock with your machine. FDM printers that have the electrical hardware to print with polypropylene include (but are not limited to) the Pulse 3D Printer, Raise3D Pro2, LulzBot TAZ 6, and Ultimaker S5.

Not sure if your 3D printer can safely extrude polypropylene? See if your 3D printer meets the following recommendations listed below.

HOTEND RECOMMENDATIONS

- If printing a polypropylene with no special blends of other polymers and/or fibers (ex: SmartMaterials Polypropylene, Ultimaker Polypropylene), no special hotend is necessary.

- If printing a polypropylene with a special blend of abrasive fibers (ex: X-Strand or BASF's Black PPGF [Polypropylene Glass Fiber] 30), a hotend that safely operates at temperatures of up to 300°C is highly recommended.

- Universal hotends we recommend for this capability include (but are not limited to) E3D's V6 All-Metal Hotend, Slice Engineering's Mosquito All-Metal Hotend, and Micro-Swiss All-Metal Hotend.

- An abrasive resistant nozzle is highly recommended when printing with abrasive fibers such as carbon and glass. These materials will wear out non-abrasive nozzles quickly, which will cause inconsistent extrusions during the printing process.

- Abrasive resistant nozzles we recommend include (but are not limited to) Olsson Ruby Nozzles, Nozzle X, and any hardened steel or vanadium nozzles.

PRINT BED RECOMMENDATIONS

- A heated bed that can safely operate at temperatures of up to 100°C is required.

- LayerLock Build Surface for Polypropylene is the build surface we've seen produce the most consistent, successful results. Designed to succeed with polypropylene, certain polypropylene blends, and OBC filament, LayerLock Build Surface sheets provide the strong adhesion necessary to keep prints from warping. We highly recommend LayerLock Build Surface as it is available in medium to large sheets that can be cut to size for your print bed.

- Packing tape is a possible alternative you can find around the house and in most stores. However, please note that it does require multiple strips of tape that must be carefully laid down (no creases or air bubbles), must be replaced more frequently, and may come with a few limitations (depending on what type of filament you are printing with). Also, confirm that the packing tape is made out of polypropylene as any other packing tape will not work.

ENCLOSURE RECOMMENDATIONS

- Only required if printing in an area that is cold or where the temperature is inconsistent. View the wide variety of 3D printer enclosures available here.

HOW TO AVOID WARPING AND SHRINKAGE

Filaments that warp and/or shrink during 3D printing are nothing new among the current line of thermoplastics available on the market for both professionals and everyday hobbyists. Each type of material has its own special set of print settings and conditions it needs to succeed such as flexibles (TPU, TPE) benefiting from a PrintDry for quality print results and nylon/nylon-based materials like NylonX and NylonG heavily benefiting from both a PrintDry and LayerLock Garolite Build Surface for maximum print success. For polypropylene, a LayerLock Build Surface and polypropylene bed adhesion solution will maximize your success when 3D printing with this material. Depending on the temperature conditions of your workspace, an enclosure may also be recommended.

Achieving a strong bond between the first layer of your print and the heated bed's build surface is crucial for successfully avoiding warping. Like other filaments, printing too close can cause your part to stick too well to the bed and printing too high can lead to the material not sticking. What steps can you take to get that ideal first layer?

- Choose the right build surface.

- Level your bed.

- Set your nozzle at the appropriate height.

LayerLock Build Surface for Polypropylene has provided the most consistent results based on the continuous testing our engineers have been performing for months. Polypropylene has a strong tendency to warp as it tends to be extremely limited to what it likes to stick to and be sensitive to temperature. This thermoplastic loves sticking to our LayerLock Build Surface so you can rest easy knowing that first layer will stay firmly adhered to the build surface during the entire duration of the print. For easy removal post-printing, we recommend combining LayerLock with a bed adhesion solution specifically designed for polypropylene before the start of your print.

Before you start printing on any new bed surface, always remember to level your bed and calibrate your nozzle height to adjust for the print bed's height difference. With LayerLock Build Surface, it is essential to achieve the correct layer height because extruding too low may cause your print to fuse to the bed surface. When adjusting layer height, we always recommend starting higher than you normally would because that prevents the possibility of having your print fuse to the bed. A great starting point would be beginning a test print at a 1mm height away from the bed surface and working your way down. Optimal nozzle height is achieved when you see the filament extruded on the bed with a width of about 1 mm.

As for shrinkage during 3D printing, that shouldn't be an issue when following our recommended print settings below on a LayerLock Build Surface for Polypropylene in a room with consistent room temperature. Our engineers have been performing these tests on our open-frame Pulse 3D Printers and have been successfully producing polypropylene parts! However, if you are limited to printing in a room below 70°C or an area with air conditioning, we highly recommend using a 3D printer enclosure to ensure your parts are being produced in a consistently warm environment. Cold air can easily cause your parts to cool too fast during printing which can lead to cracks in your prints, leaving them unusable in the end. If you don't have an enclosure and are not located in a consistently warm environment, check out our catalog of 3D printer enclosures and enclosure kits. Follow our recommended settings below with our recommended 3D printer accessories and you will be closer to polypropylene 3D printing success!

RECOMMENDED POLYPROPYLENE PRINT SETTINGS ON LAYERLOCK BUILD SURFACE:

- Extruder Temperature:

- 210°C - 230°C (SmartMaterials SmartFil Polypropylene, Ultimaker Polypropylene)

- 250°C - 280°C (X-Strand GF30-PP, BASF Black PPGF 30)

- Bed Temperature: 50°C - 80°C bed

- Bed Adhesion Solution: Magigoo Bed Adhesion for Polypropylene or SmartMaterials SmartStick

- Layer Height - Relative to the brand and type of polypropylene filament being printed

- To find the ideal layer height, start 1mm above the print bed and baby step down until your extruded filament looks to be about 1mm in width.

- Print Speed: 30 - 50mm/s

- Brim: 25 - 35mm

- Raft - May be useful for parts with a very large surface area; otherwise not necessary

- Layer Cooling Fan - May be needed when layer time is below 20 seconds; otherwise not recommended

READY, SET, PRINT!

We hope these tips help you succeed with 3D printing polypropylene! With this thermoplastic found in many common household products, PP is the perfect end-use material for prototyping straight from your workbench. If you have any further questions, feel free to hop on our forum filled with helpful posts and fellow enthusiasts working together to create a smooth, enjoyable 3D printing experience.

Happy Printing!

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.