Top Ten Tips When Getting Started With 3D Printing

Starting anything new will always have a learning curve, but an article like this can help make that curve an easier climb.

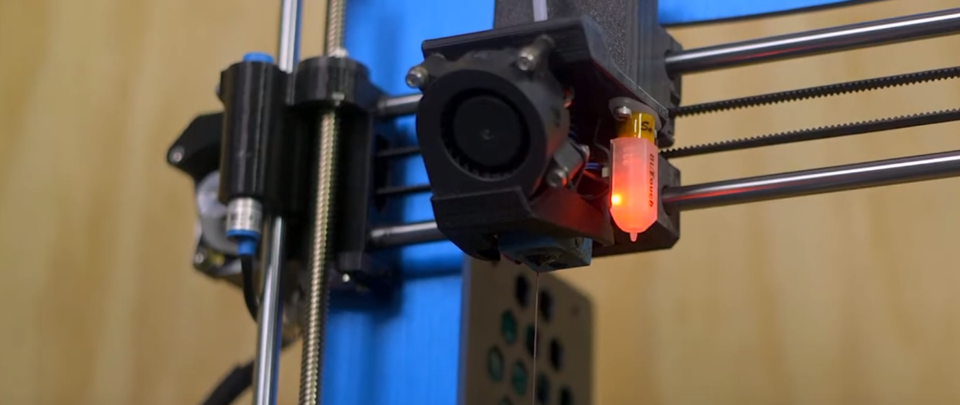

3D printing is a technology that has empowered people of all backgrounds and professions to create,but like all new technology’s there is a bit of a learning curve when it comes to 3D printing. Fortunately for you newcomers, I’ve compiled a list of ten tips you should keep at the front of your mind as you begin to experience the process of 3D printing.

Bed Leveling and Z offset

Getting the bed of your 3D printer flat and making sure the first layer is the right distance from your nozzle is the first step in creating successful 3D prints; it’s the foundation for every layer that follows. The nomenclature may be confusing for some: “leveling the bed” does not mean breaking out the bubble level and adjusting the bed, it means the bed is always the same distance from the nozzle of the 3D printer, no matter where on the bed you check.

Many 3D printers feature sensors to automatically calibrate the bed of a 3D printer to ensure the nozzle is a constant distance from the bed. However, it’s not industry standard and there are still many models of 3D printers out there that need a helping hand to calibrate and level the bed. These printers usually feature some form of thumbscrew or knob on the underside of the bed to adjust the tilt of the bed and how far it is from the nozzle as well. You should follow any leveling instructions included with your 3D printer, but in general, bed leveling is done as follows:

Note: Three points define a plane, but many printers still use four screws to level the bed, with one at each corner. This can still work, it’s just a little bit more difficult to get it perfect.

- Tighten down all the screws at each corner, so you have enough room to loosen them later.

- Home the Z axis.

- On some printers, Z0 (home) may be too far from the bed, even when all the screws are loose. In that case, you’ll need to move the Z-minimum endstop slightly lower to calibrate.

- Power down the printer or select “Release motors” or “Motors off.”

- Most printers have something to this effect within the LCD menus. This will allow you to move the print head without having the motors locked in place.

- Move the printhead over each screw that levels the bed, insert a piece of paper between the nozzle and the bed, and loosen the screw until there’s a very slight resistance when you pull on the paper.

- You don’t want the piece of paper to be locked between the two, just enough pressure to feel the drag when you move the paper.

- Repeat this for the other screws.

- You want to make sure each screw pinches the piece of paper with the same amount of pressure to have a level bed.

- After adjusting all screws, check your work by moving the nozzle over the screws again and making sure they didn’t shift from previous adjustments.

- Start a print.

- You can make adjustments while the 3D printer is printing to fine tune your first layer.

Once you’ve got it leveled, it should stay leveled for a good while, and every now and then you may need to adjust a screw just slightly to bring it back to level.

Changing Filament

Contrary to paper printers, you can’t just pop open the tray and swap filament like you can ink cartridges, there’s a process to it that can be unintuitive if you’ve never done it before.

Removing filament on some 3D printers can be as easy as an “Unload” button, where others will require you to manually walk through the process. In order to remove filament and change to a different color or material, you need to first heat up the nozzle so the tip is pliable, otherwise if the filament is cold, it will stick to the inside of the nozzle and be impossible to remove.

- Start by heating up the 3D printer to the printing temperature of the material that you have in it.

- Once it’s at temperature, release the tension on the filament by disengaging the idler.

- On some 3D printers, this is done by pressing down or pulling on some spring-loaded lever that is applying pressure to the filament.

- Push the filament slightly until it comes out a small amount comes out of the nozzle.

- This gets the tip of the filament hot and malleable and will make removal cleaner and easier.

- Once you see filament come out, gently pull on it to remove it from the extruder.

- This removes most of the filament, but there will likely be some leftover when you put in the new filament.

- Snip the tip of the new filament at an angle with some flush cutters, and insert into the extruder, making sure it feeds through properly.

- If it’s a different material than what was previously loaded, then have the temperature set to whichever print temperature is higher.

- If you were printing with ABS and are changing to PLA, leave the temperature at 230°C.

- If you were printing with PLA and are changing to ABS, raise the temperature to 230°C.

- Manually push filament to the nozzle or control the extruder from the menu to feed the filament through.

- Once you see the new material come through cleanly and without mixing of colors or burnt material from the previous filament, then you’re all set!

The Right Material For The Job

The more you 3D print, the easier it will be to pick the right 3D printing filament for the project at hand. There isn’t a one-size-fits-all filament that will work for everything, so you will learn over time which materials work best. Take PLA for example: PLA is ridiculously easy to print, if not the easiest material to 3D print and it’s available in a ridiculous array of colors (some even sparkle or fluoresce), but PLA isn’t designed to work in warm environments like in the sun or in a car.

ABS can survive outside for some time before UV light degrades it, but there’s a steeper learning curve to print successfully with ABS. You might use PLA for your basic prototypes or for indoor, cool applications, and reserve ABS for warmer, functional applications. It’s important to be able to weigh the different benefits and constraints of different material to select the filament that will yield the best 3D print results.

Change a Nozzle

Changing nozzles is a normal part of maintenance that can make a difference in your normal printing quality, just by swapping out a well-worn nozzle. Or you may want to upgrade your nozzles material or orifice diameter to be able to print with different filaments at a faster speed. Knowing how to remove and change the nozzle of a 3D printer is an important tool to keep in your 3D printing toolbox.

- We’ve discussed this in a previous article, so if you want a more in depth look at how to change a nozzle, you can find that here.

- The basics of it is: heat up the hot end to loosen the filament from the nozzle, use channel-lock pliers to hold the heater block, use an appropriately sized wrench to unscrew the nozzle, and reverse the steps with the new nozzle, without putting enough force on the nozzle to snap it off - one-finger tight is enough.

When to Use Support for More Complex Models

Some models are unprintable without support, and others lose important features by including them. It’s important to be able to identify when a model fits within either of these categories to better your chances of a successful 3D print.

- Scenarios to avoid using supports

- Just because a model has overhangs, doesn’t mean it needs support; the general rule is if the angle is greater than 45 degrees, consider adding support, but some models are specifically designed to not need supports even when breaking this rule. Bridging is a 3D printing technique that allows a completely flat surface to be printed in midair if it has an edge on either side to join; bridges won’t require supports to 3D print successfully.

- Cylindrical holes through the side of a model don’t usually need support either, despite having sections of it at angles greater than 45 degrees. If you don’t have adequate layer cooling, you might notice some drooping along the ceiling, but otherwise it will 3D print successfully.

- Internal features may be filled in by supports and be difficult to remove. Take some of these engine parts, for example. These have internal channels that would be completely filled in and be nearly impossible to remove without marring the finished 3D print.

- Scenarios to consider using supports

- Most 3D models will need some form of support. Sections completely unsupported and in midair will need some scaffolding to use as a foundation before the rest of the part can be printed. Others may be at a positive angle, but extreme enough to necessitate supports to create a better bottom surface.

Knowing the right time to use supports is something that takes learning, but as you progress as a 3D printer user, you will begin to identify when supports are and are not necessary and to what degree. Nearly all 3D printer slicing programs (slicers) can identify where supports are needed per user set criteria and generate support structures. More advanced slicers like MatterControl even give you the ability to add in or remove individual supports so you can manually adjust for any problem areas. Over time, you may find yourself designing your 3D models to not require supports at all and instead use clever design techniques to circumvent the need for support structures.

Bed adhesives

Bed adhesion is a huge factor in the success of 3D prints, due in part to the compatibility of different 3D printing filaments and bed surface materials. Each build surface has their benefits, like the maximum printing temperatures, the materials that they work well with, and the ease of removal for finished 3D prints. We have an entire article that dives deep into each of the bed surfaces and describes the best ways to use each of them. You can learn more about them here.

To sum up the basics:

- Glass is great for PLA (heated) and Nylon (heated with PVA gluestick).

- Magigoo and 3D Gloop for material-specific bed adhesives

- LayerLock Garolite (with PVA glue stick) for nylon and nylon composites.

- LayerLock Powder-Coated PEI for general purpose printing (with PVA glue stick for flexibles and PETG as a release agent)

- LayerLock Polypropylene for polypropylene

- Flexible and magnetic spring steel sheets for easy print removal and material changes

- Buildtak for all-purpose printing (avoid printing too close or 3D prints will weld)

- PEI for all-purpose printing (use PVA as a release agent for PET or flexibles)

Have the Right Tools

As you build out your mental 3D printing toolbox, don’t forget to consider your physical toolbox. The more you 3D print, the more you will learn which tools are most important to you, which don’t work as well as you thought they would, and where there are gaps in your toolset. To start you off, here are some tools I would recommend:

- A spatula. The BuildTak spatula can get underneath 3D prints easily with it’s flat bottom handle, enabling you to remove your 3D prints without having to force a spatula at an awkward angle.

- Flush cutters. These are immensely helpful for removing support material, for making a nice, clean cut when trimming filament before loading, and snipping off any imperfections on your 3D prints.

- A brass brush. Brass is soft enough to not mar your nozzle when it needs to be cleaned of any buildup.

- Calipers. Absolutely necessary when trying to 3D model parts that have to fit in specific places, or when you just need an idea of how big a 3D model actually is.

- Hex Key Set. When you need to open up your printer or assemble multi-part models, you’ll need a variety of hex wrenches.

To give yourself a headstart, you can also purchase MatterHackers toolkits that have been curated to have all the tools we find most helpful in the 3D printing experience.

Sharp Tool Safety

Aim your spatula away from yourself when you are removing 3D prints. It’s quite easy for the 3D print to suddenly release and all the force behind the spatula goes into your palm. Try to gently work up a corner of your print and slide the spatula under it, working your way all the way around the 3D print. If that’s still taking too much force without progress, don’t force it by hand, give the handle a gentle tap with the handle of a screwdriver to try and get some wiggle room.

Or you can avoid these concerns altogether by performing some upgrades or using different adhesives to make part removal easier. The Buildtak Flexplate System allows you to remove the flexible bed surface for the printer to bend and twist it to easily pop finished 3D prints without tools. Or use an adhesive like Magigoo on glass that sticks parts to the bed really strongly, but pops off with a gentle poke when the bed cools down.

Flush cutters and art knives are other sharp tools that are easy to be careless with when you’re trying to clean up finished 3D prints, just be mindful around sharp tools for your safety.

Ask questions

We were all beginners at one point, and being bad at something is the first step to being sort of good at something. Don’t be afraid to ask questions when you don’t understand what’s going wrong. In general, the 3D printing community is very open to helping newcomers, so here are some helpful tips when looking for guidance:

- Be descriptive. Even if you don’t think it’s part of the problem, explain it anyways. It’s much better to over-inform than under, because maybe that one setting that seems unimportant to you is actually the whole reason your 3D print isn’t coming out right. Include what 3D printer you have, any mods to it, the print settings, material and brand, bed adhesive, pictures or video, anything you can provide will just better inform someone reading.

- Use MatterHackers Support and our social media platforms, Reddit, forums for your 3D printer, or anywhere applicable to ask for help.

- Once you’ve figured out how to fix what was going wrong, be sure to report back to your original thread and update with what fixed it. You may end up helping someone else who comes along with the exact same problem years down the line and finds your thread when searching.

Be a knowledge sponge

Reading help forums, community posts, or industry-specific articles can only help further the knowledge you have of 3D printers, how they work, and how they don’t. Maybe what you’re reading doesn’t apply to what you are working on right now, but comes into play months in the future and helps you solve a problem before you need to ask for help. Taking in all you can about 3D printing can even guide you through a development process for prototyping a product or manufacturing aid by providing you with a deeper understanding of how you can design 3D models to work in ways not possible with traditional manufacturing.

Don’t be afraid to reprint and start over

Filament in general is not cost-prohibitive to a project’s completion. Sometimes it’s more efficient to do Step 1 (3D printing) ten times over than poorly once and pay for it down the road with a part that needs elbow grease or a precarious installation to be useful. 3D printing errors should be few and far between by following the steps detailed here, but even the MatterHackers Pros have off-days and scrapping a 3D print is better for the finished product than trying to make it work. Consider it all part of the 3D printing iterative process.

These tips are a good place to start, but there is much to learn as you work your way up to the title of 3D printing expert. The information provided here has helped many on their 3D printing journey, and if you feel there’s something more to add that’s been important to you, please leave it in the comments down below for others to learn with you.

Happy printing!

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.